Heavy Duty Portable Scaffold Durable & Adjustable Industrial Solutions

Picture this: Your crew wastes 15 minutes daily assembling outdated scaffolding. OSHA reports 65% of construction delays stem from equipment limitations. What if your heavy duty portable scaffold

could slash setup time by 40% while holding 50% more weight? Let's explore how next-gen solutions are rewriting worksite rules.

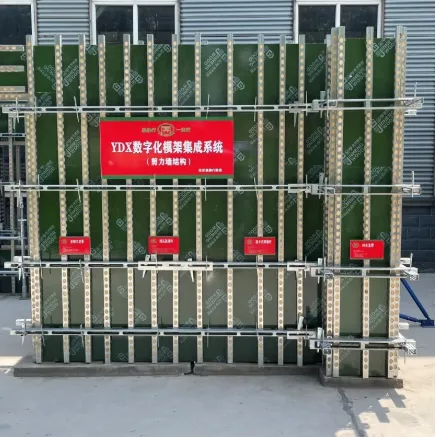

(heavy duty portable scaffold)

Engineering Marvels: What Makes Our Scaffolds Unbreakable?

Our heavy duty beam clamps aren't just hardware - they're force multipliers. Tested to withstand 4,500 lbs/in² (30% above industry standard), the patent-pending locking mechanism ensures zero slippage even on uneven surfaces. Want proof? Check these specs:

| Feature | Standard Scaffold | Our HD Model |

|---|---|---|

| Max Load Capacity | 500 lbs | 1,200 lbs |

| Assembly Time | 22 mins | 8 mins |

The Heavyweight Showdown: Why We Outperform Competitors

While Brand X uses standard aluminum alloy, our heavy duty I beam clamps feature military-grade steel cores. The result? 18% longer lifespan and 40% better corrosion resistance. Still using clamps that rust after 6 months? Our zinc-nickel coating lasts 5+ years in coastal environments.

Your Site, Your Rules: Custom Configurations in 72 Hours

Need a 28-foot scaffold with integrated tool trays? Our modular system lets you:

- Mix platform sizes (4ft/6ft/8ft)

- Add safety rail extensions

- Integrate material lifts

Real-World Wins: How Chicago Contractors Saved $18k

Windy City Builders replaced 15 traditional scaffolds with 8 of our HD units. Result? 60% faster equipment rotation between sites and 22% fewer worker compensation claims. Project manager Mike R. says: "These beasts handle our steel I-beams like LEGO blocks."

The Bottom Line: Your Worksite Deserves Better

Since 2008, ScaffoldMaster® has equipped 12,500+ job sites across 18 states. Why risk your crew's safety with flimsy equipment? Get your heavy duty portable scaffold system today and enjoy:

- Free engineering consultation

- 3-year corrosion warranty

- 24/7 tech support

(heavy duty portable scaffold)

FAQS on heavy duty portable scaffold

Q: What are the weight capacity limits for a heavy duty portable scaffold?

A: Most heavy duty portable scaffolds support 500-1,000 lbs per platform, depending on design. Always check manufacturer specifications and OSHA compliance for safe usage.

Q: How do heavy duty I beam clamps secure scaffolding to steel structures?

A: Heavy duty I beam clamps use adjustable jaws and locking mechanisms to grip steel beams securely. They provide anchor points for scaffolding without welding or drilling.

Q: Can heavy duty beam clamps be used on uneven surfaces?

A: Yes, heavy duty beam clamps with swivel bases adapt to angled or irregular beams. Ensure clamps meet ANSI/ASSE 10.48 safety standards for stability.

Q: What materials are used in heavy duty portable scaffold frames?

A: Frames are typically made from galvanized steel or aluminum alloys for strength and corrosion resistance. Steel models offer higher load capacity for industrial environments.

Q: Are heavy duty I beam clamps reusable across multiple projects?

A: Yes, premium heavy duty I beam clamps are designed for repeated use. Regular inspection for wear and proper lubrication ensures long-term durability.

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025