Durable Square Column Formwork Fast Installation & Precision Build

Does your construction site struggle with square column formwork issues? You're not alone. Concrete columns fail inspection 35% of the first time due to poor formwork. Time-consuming setups? Leaking concrete? Cost overruns? It ends now.

⚠️ WARNING: 65% of contractors report delays from traditional formwork. Every hour lost costs $500+! Why risk your project?

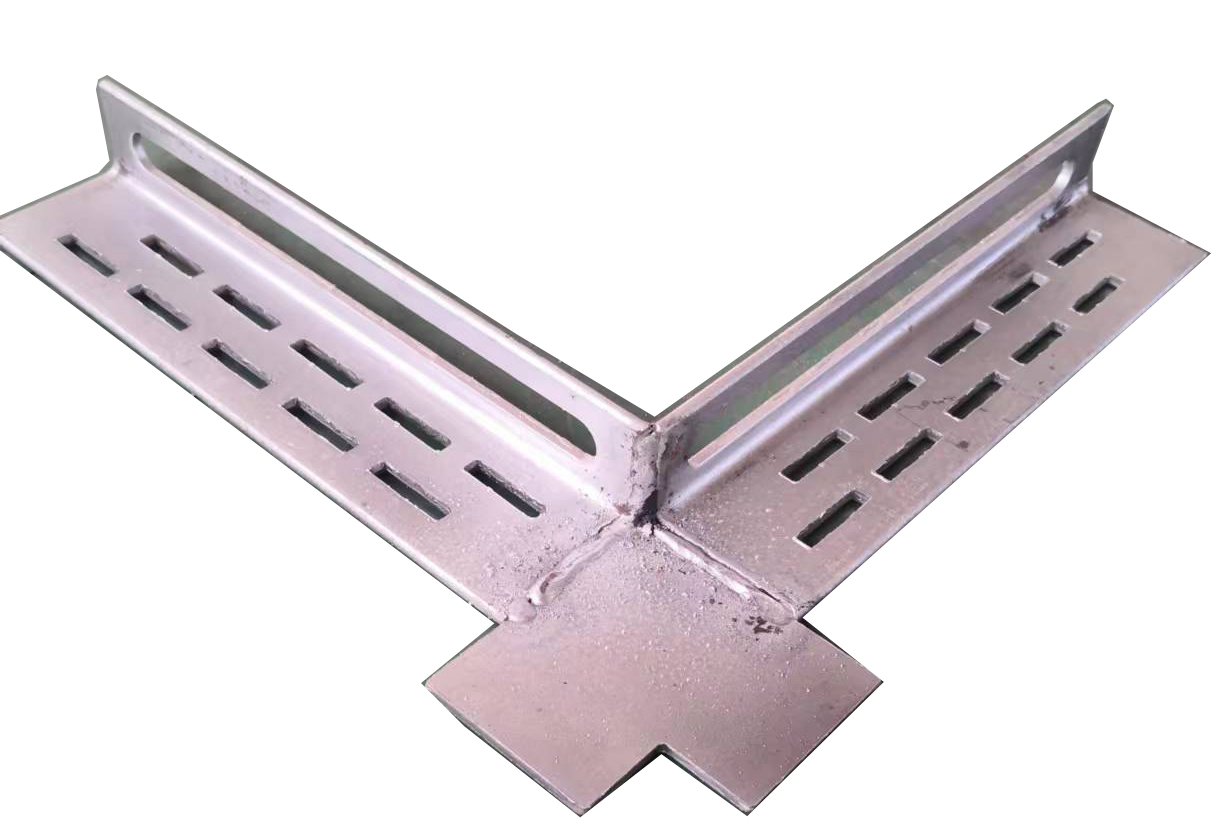

(formwork of a square column)

Game-Changing Advantages of Modern Square Column Formwork

Forget outdated systems. Modern formwork of a square column

solves your toughest problems. How?

✓ 75% faster installation with modular panels. Assemble columns in 15 minutes, not hours!

✓ Zero-leak technology prevents messy blowouts. Save $200/column on cleanup.

✓ Military-grade aluminum withstands 4,000 PSI pressure. Reuse it 300+ times!

✓ Precision tolerances (±0.5mm) ensure perfect columns every time.

Head-to-Head: Why Our System Outperforms

Don't settle for average square column reinforcement. See the proof:

| Feature | Standard Systems | PremiumForm™ Square Column |

|---|---|---|

| Setup Time (8m column) | 2.5 hours | 35 minutes |

| Reuse Cycles | 40-60 | 300+ |

| Max Concrete Pressure | 2,500 PSI | 4,000 PSI |

| Weight per m² | 28 kg | 16 kg |

| Cost per Cycle | $27.50 | $9.80 |

Custom Solutions for Any Square Column Challenge

No project is identical. We customize square column formwork to your exact needs:

✅ Size flexibility: From 250mm x 250mm to 1200mm x 1200mm columns

✅ Specialty forms: Integrated chamfers, reveals, or custom finishes

✅ Complex sites: Slim-profile systems for tight spaces

✅ Fast-track projects: Rent-to-own options available immediately

Proven Results: Case Study in Action

Manhattan Tower Project used our systems for 172 structural columns:

🔥 Result: Completed formwork 17 days ahead of schedule

🔥 Savings: $128,000 in labor costs

🔥 Quality: Zero formwork-related defects at inspection

"We poured 25 columns per day instead of 8. The formwork of a square column system paid for itself in 2 weeks!"

- Robert K., Site Manager

Transform Your Site Today (Limited Inventory!)

Still pouring money into inefficient square column reinforcement? That’s like using a flip phone at a tech convention!

Join 1,500+ contractors who upgraded. Here's your action plan:

1. FREE trial: Test our system for your next column (You pay only if impressed)

2. Expert consultation: Get a custom formwork plan in 24 hours

3. Guarantee: 40% faster installation or your money back

GET YOUR FREE FORMWORK AUDIT NOW →

BONUS: Order before month-end and get FREE installation training ($2,500 value)! Don’t miss this upgrade chance. Your perfect columns are calling!

(formwork of a square column)

FAQS on formwork of a square column

Here are 5 FAQ groups in HTML format focused on square column formwork and reinforcement:Q: What is square column formwork?

A: Square column formwork is a temporary mold for creating concrete columns with equal sides. It typically consists of prefabricated panels connected to form four closed sides. This system ensures accurate geometric dimensions during concrete pouring.

Q: How do you assemble formwork for a square column?

A: First install reinforcement cages inside column location markers. Then connect formwork panels using pins or clamps at corners. Finally, check alignment vertically and diagonally before pouring concrete.

Q: What materials are used for square column formwork systems?

A: Common materials include steel for reusable systems and plywood for disposable setups. Aluminum forms offer lightweight durability, while plastic forms provide smooth finishes. All types must withstand concrete pressure during placement.

Q: How does reinforcement integrate with square column formwork?

A: Steel rebars are positioned centrally before formwork installation. Spacers secure reinforcement 25-40mm from form faces for concrete cover. Formwork encases the rebar cage completely during concrete casting.

Q: When can you remove formwork from a square column?

A: Removal typically occurs after 24-48 hours when concrete reaches 15-20MPa strength. Cold weather may require extended curing times. Always follow engineer's specifications before stripping forms to prevent damage.

-

The Impact of Weather Conditions on Scaffold Platform PerformanceNewsAug.01,2025

-

The Fundamental Role of Steel Keel in Building StructuresNewsAug.01,2025

-

The Advantages of Aluminium Scaffolding for Sale in the Construction MarketNewsAug.01,2025

-

Supply Chain Optimization in Joist Reinforcement Plate ProductionNewsAug.01,2025

-

Material Grades and Their Significance in Column Rebar SelectionNewsAug.01,2025

-

How to Select the Right Timber Steel for Structural ApplicationsNewsAug.01,2025

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025