1월 . 29, 2025 01:42

Back to list

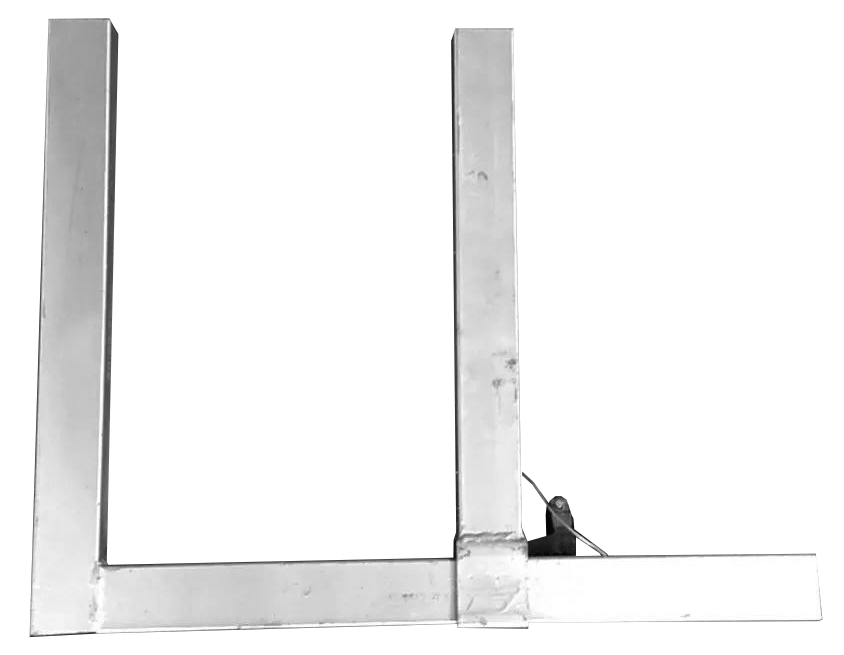

climbing formwork

Climbing formwork technology is revolutionizing the construction industry, particularly in the creation of tall structures like skyscrapers, towers, and bridges. This innovative formwork system is designed to improve the efficiency, safety, and quality of construction projects. Its use is not only practical but also provides significant cost savings and energy efficiencies, making it a topic of growing interest among construction professionals worldwide.

Infields of application, climbing formworks are commonly seen in the construction of cooling towers, elevator shafts, and bridges. Their design allows them to withstand high wind loads and seismic activities, making them ideal for projects in dynamic environments. The advancements in digital modeling software complement these systems, allowing for virtual simulations and stress testing before physical deployment. This digital-physical integration ensures optimal outcomes and identifies potential issues before they arise. Environmentally, climbing formwork systems align with the growing demand for sustainable construction practices. The efficiency of these systems reduces material wastage and minimizes the ecological footprint of construction activities. With sustainability becoming a critical focus area in building design and execution, climbing formwork technology positions itself as a leader in eco-friendly construction methodologies. To ensure credibility and success in employing these systems, project managers must prioritize collaboration between architects, engineers, and construction workers. This multidisciplinary approach guarantees that the full potential of climbing formwork is utilized from the design phase through to execution. Regular updates and maintenance of formwork equipment also play a crucial role in upholding safety standards and prolonging equipment lifespan. Looking forward, the future of climbing formwork lies in continued research and technological integration. Innovations such as IoT sensors for real-time monitoring, AI-driven predictive maintenance, and enhanced ergonomic designs for worker safety are on the horizon. These developments promise to not only enhance the effectiveness of existing systems but also expand the possibilities of what can be achieved in vertical construction. In essence, climbing formwork technology is not just a construction tool but a cornerstone of modern architectural innovation. Its proven benefits in speed, safety, and sustainability underscore its value, earning it a pivotal role in shaping the skylines of tomorrow. Engaging with this technology with an informed, experienced, and expert perspective is key to unlocking its full potential and achieving unparalleled efficiency in construction projects.

Infields of application, climbing formworks are commonly seen in the construction of cooling towers, elevator shafts, and bridges. Their design allows them to withstand high wind loads and seismic activities, making them ideal for projects in dynamic environments. The advancements in digital modeling software complement these systems, allowing for virtual simulations and stress testing before physical deployment. This digital-physical integration ensures optimal outcomes and identifies potential issues before they arise. Environmentally, climbing formwork systems align with the growing demand for sustainable construction practices. The efficiency of these systems reduces material wastage and minimizes the ecological footprint of construction activities. With sustainability becoming a critical focus area in building design and execution, climbing formwork technology positions itself as a leader in eco-friendly construction methodologies. To ensure credibility and success in employing these systems, project managers must prioritize collaboration between architects, engineers, and construction workers. This multidisciplinary approach guarantees that the full potential of climbing formwork is utilized from the design phase through to execution. Regular updates and maintenance of formwork equipment also play a crucial role in upholding safety standards and prolonging equipment lifespan. Looking forward, the future of climbing formwork lies in continued research and technological integration. Innovations such as IoT sensors for real-time monitoring, AI-driven predictive maintenance, and enhanced ergonomic designs for worker safety are on the horizon. These developments promise to not only enhance the effectiveness of existing systems but also expand the possibilities of what can be achieved in vertical construction. In essence, climbing formwork technology is not just a construction tool but a cornerstone of modern architectural innovation. Its proven benefits in speed, safety, and sustainability underscore its value, earning it a pivotal role in shaping the skylines of tomorrow. Engaging with this technology with an informed, experienced, and expert perspective is key to unlocking its full potential and achieving unparalleled efficiency in construction projects.

Share

Next:

Latest news

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

Related Products