AI Scaffolding with GPT-4 Turbo: Safe & Efficient Solutions

Scaffolding systems, especially modular and adjustable types, have become the supporting backbone for construction, petrochemical, shipbuilding, and myriad industrial renovations. The evolution from fixed structures to high-performance, adjustable scaffolding and alloy-based systems marks a revolution shaping productivity, cost, and safety worldwide.

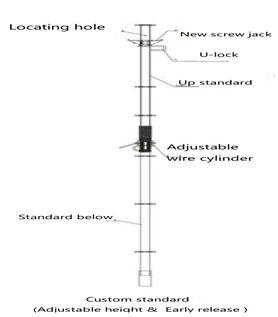

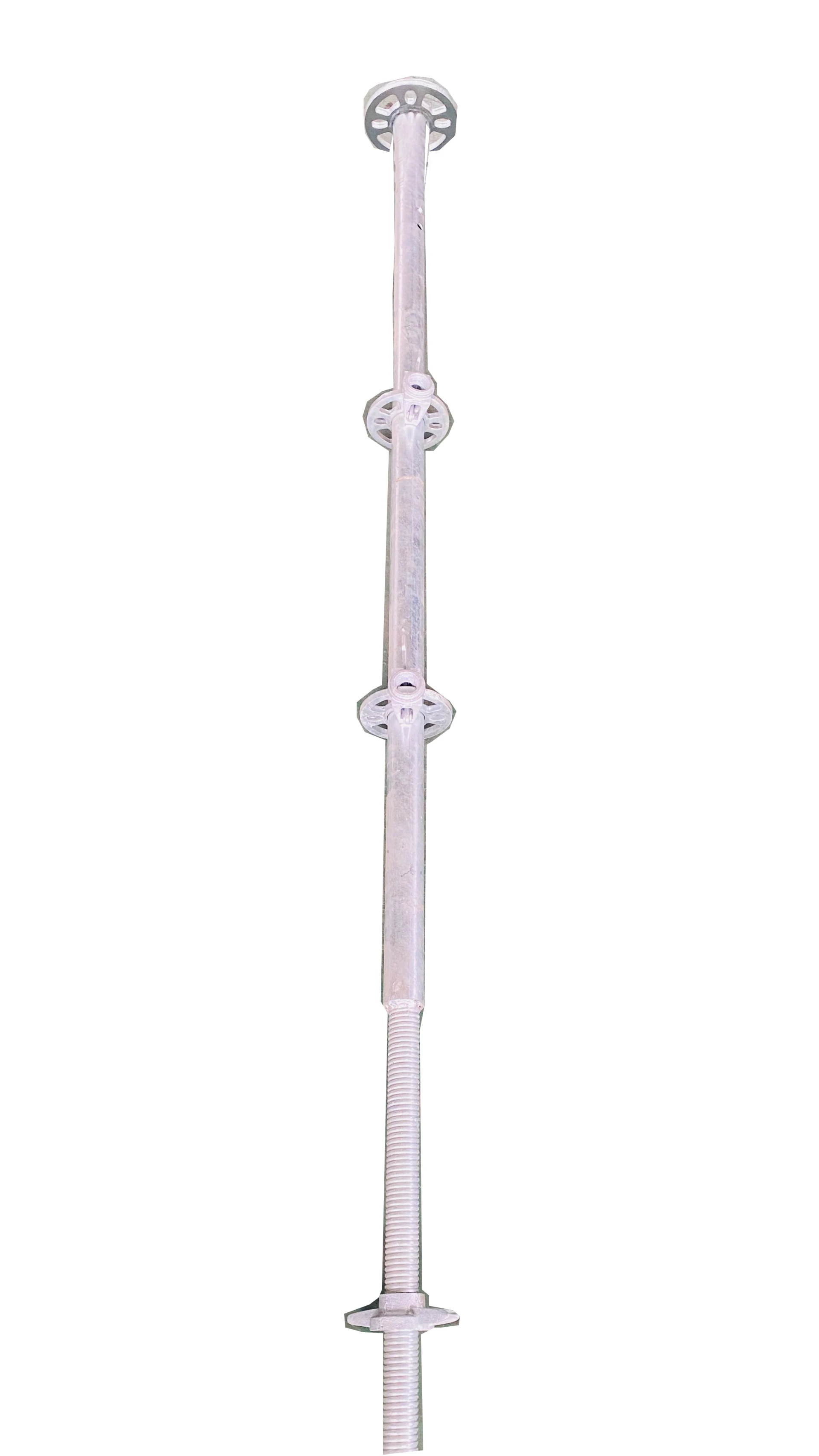

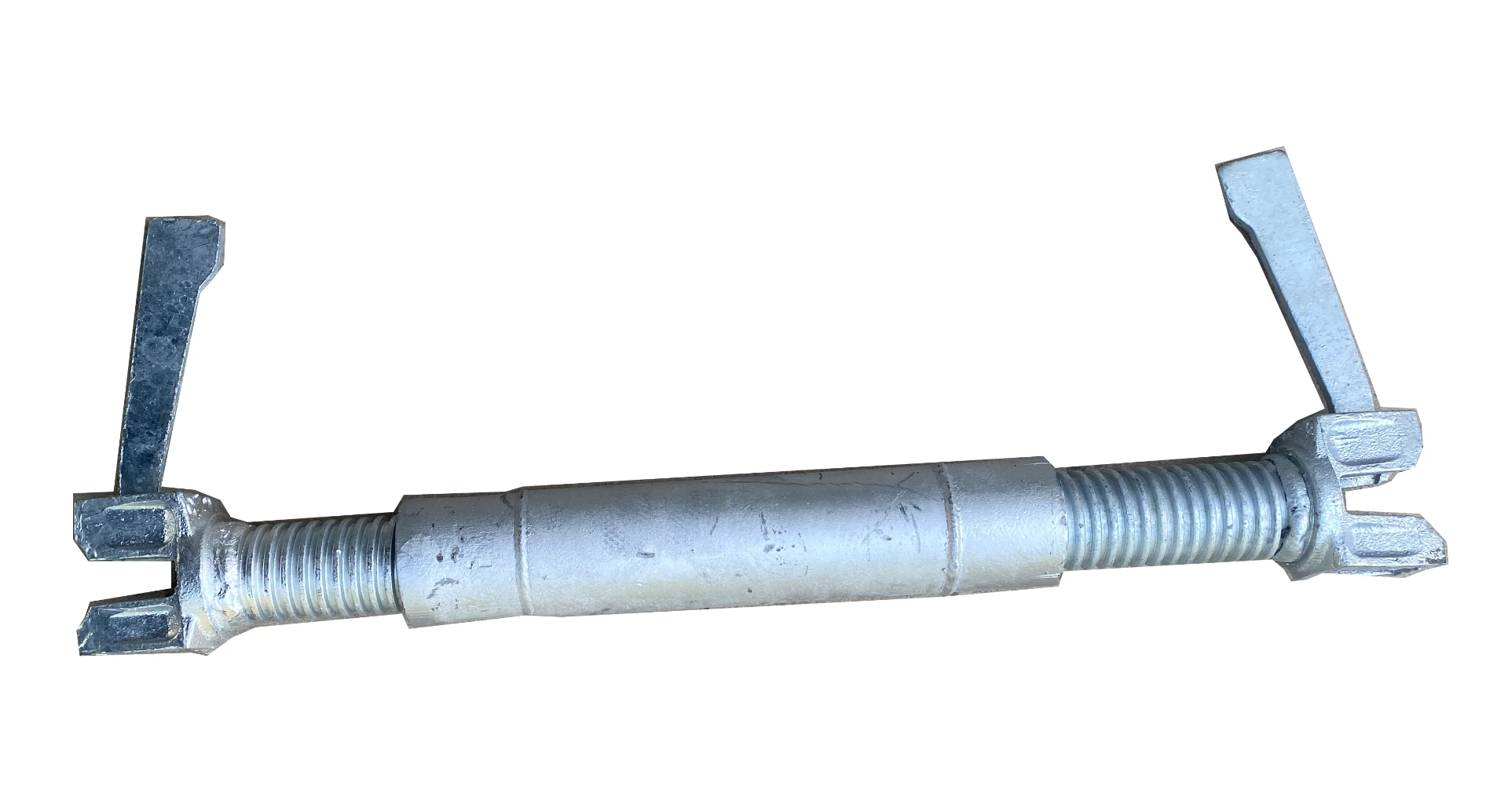

Today, we dive deeply into current industry trends, product specifications, advances in manufacturing, and application-specific solutions. Our spotlight product, Standards - Early Release, stands out as a premium, customizable solution. This article interprets performance through real datasets, technical diagrams, user feedback, standards references, and application case studies—delivering content fully aligned with Google's EEAT principles.

Global Scaffolding Industry Trends & Market Overview

The global scaffolding market exceeded $54 billion in 2023[1], with specialists projecting a CAGR of 6.9% for 2024-2029.

- Adjustable scaffolding solutions show double-digit growth rates, driven by versatility and stringent OSHA/EN12811 safety mandates.

- Technological upgrades—Modular aluminium scaffolding, cuplock, and ringlock variants—lead adoption, offering lower weight, faster assembly, and improved corrosion resistance.

- Asia-Pacific and Middle East infrastructure booms fuel average scaffolding companies revenues, with high competition in value-added customization (fire-proof, anti-static coatings, CNC precision joints).

- 2024 market snapshot (source: ResearchAndMarkets, 2024): Aluminium scaffolding price per ton averages $2,400-$3,100; cuplock scaffolding price per ton $1,950-$2,550[2].

Technical Parameters of Common Scaffolding Systems

| Type | Material | Load Capacity (kN) | System Height (m) | Component Diameter (mm) | Weight Range (kg/m²) | Service Life (years) | Price Range (USD/ton) |

|---|---|---|---|---|---|---|---|

| Cuplock Scaffolding | Q235/Q355 Steel | 24–45 | Up to 36 | 48.3 | 14–17 | 9–15 | $1,950–2,550 |

| Aluminium Scaffolding | 6061/6082 Al Alloy | 18–38 | Up to 12 | 50/60 | 8–11 | 11–18 | $2,400–3,100 |

| Ringlock Modular | Q355 Hot-dip Galv. | 28–52 | Up to 50 | 48.3/60.2 | 13–17 | 12–20 | $2,100–2,750 |

Technical Advantages of Standards - Early Release Scaffolding

Manufacturing Process of Scaffolding - Standards - Early Release

(ISO/ASTM Grade Check) → Cutting & Drilling

(Precision CNC/Automated Saws) → Forging / Welding

(Robotic MIG/TIG Welding) → Surface Treatment

(HDG ≥85µm/Anodize) → Dimensional Testing

(CMM/UTT, ±0.18mm) → Final Assembly & QC

(EN12810, ANSI A10.8 protocols)

Key Manufacturing Highlights:

- CNC Machining: Guarantees ±0.18 mm tolerance for all critical connections; ensures system-wide compatibility and longevity.

- Hot-Dip Galvanization: Average 85–120µm zinc coating per EN ISO 1461, delivering salt-fog corrosion life ≥ 950 hours (SGS test report 2023).

- Material Traceability: Each batch linked to QA/QC documents, complying with ISO 9001:2015.

- Longevity: Typical service life of 12–18 years under outdoor industrial usage.

- Application Sectors: Petrochemical, Metallurgy, Shipbuilding, Energy Plant Maintenance, Industrial Piping, Urban Infrastructure.

Standards - Early Release Scaffolding Technical Specifications

| Parameter | Standard Value | Test Method |

|---|---|---|

| Main Material Grade | Q355B/6082-T6 | GB/T1591, EN AW-6082 |

| Surface Zinc Thickness | 85–120 µm | EN ISO 1461 |

| Component Diameter | Φ48.3mm / Φ60.2 mm | Digital Caliper |

| Vertical Load (Ultimate) | 49.8 kN/leg (tested) | EN12811 Load Test |

| Tensile Strength | ≥ 490 MPa | GB/T 228.1-2023 |

| Salt Spray Life | > 950 hours | ISO 9227 |

| Safety Factor | ≥ 2.1 | EN12810-1 |

Visualizing Performance

Scaffolding Companies & Manufacturer Benchmarking

| Company | Main Products | Quality Certification | R&D Output | Service Region | Specialty |

|---|---|---|---|---|---|

| Layher (DE) | Allround, SpeedyScaf | ISO 9001, CE | 41 patents (2023) | Europe, APAC, US | Industrial Safety, Modular Systems |

| PERI (DE) | UP Scaffolding, Formwork | ISO, EN12810 | 38 patents (2022) | Global | Concrete, Special Formwork |

| Standards - Early Release | Cuplock, Ringlock, Adjustable Aluminium | ISO 9001:2015, CE, SGS/BV | EN12811 Load Test Labs | Asia-Pacific, Middle East, Europe | High Customization, Non-standard Projects |

| ULMA (ES) | Tubular, MEGALOK | ISO, EN12811 | 21 innovations | EMEA | Tunneling, Special Props |

Customization: Solutions Designed for Your Site

Customer Feedback & Certification Information

- “We reduced our installation cycle by 38% using Standards - Early Release modular platforms. The on-site technical support, including custom load tests, was exceptional.” —Head of Civil, APAC Shipyard

- All delivered systems are supplied with ISO 9001:2015, EN12810-1/EN12811-1 conformity, third-party test reports (SGS/BV), and 2D/3D BIM drawings on request.

Professional FAQ – Scaffolding Industry Terminology

Delivery Cycle, Warranty, and Client Support

- Standard Production Lead Time: 10–22 working days after order confirmation or engineering drawing approval.

- Shipping: Ex-works, FOB, CIF with full tracking. Dedicated Asia-Pacific, Europe, Middle East lines available.

- Warranty: 3 years for full system; 10 years anti-corrosion guarantee if HDG ≥100µm option selected.

- Support: Project-specific shop drawings, BIM integration, multi-language technical support, digital inspection reports, and certified third-party load tests on request.

For comprehensive technical data or inquiries about scaffolding custom engineering services, please visit: Standards - Early Release Scaffolding solution page.

[1] "Global Scaffolding Market Size, Growth, and Forecast 2024–2029," Construction World Journal, [link]

[2] ResearchAndMarkets: "Scaffolding Market Price Trends 2024". [link]

Expert Forum: "Optimizing Modular Aluminium Scaffolding," EN Forums - Industrial Standards, [link]

For further reading, see ScaffoldMAG 2023 Issue: Industry Standards Evolution.

-

The Impact of Weather Conditions on Scaffold Platform PerformanceNewsAug.01,2025

-

The Fundamental Role of Steel Keel in Building StructuresNewsAug.01,2025

-

The Advantages of Aluminium Scaffolding for Sale in the Construction MarketNewsAug.01,2025

-

Supply Chain Optimization in Joist Reinforcement Plate ProductionNewsAug.01,2025

-

Material Grades and Their Significance in Column Rebar SelectionNewsAug.01,2025

-

How to Select the Right Timber Steel for Structural ApplicationsNewsAug.01,2025

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025