Feb . 20, 2025 13:36

Back to list

Scaffolding

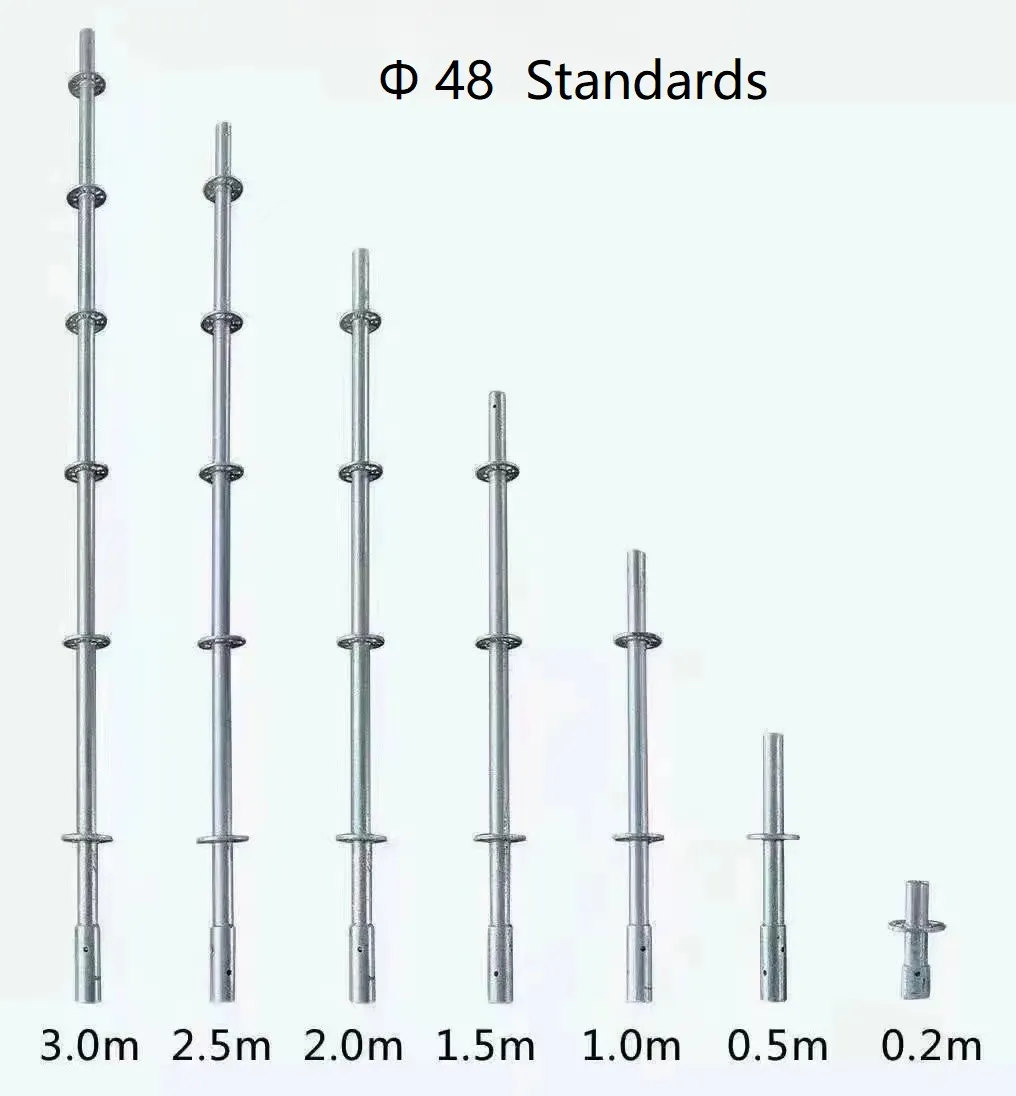

The market for steel scaffolding tubes has seen a remarkable evolution, driven by advancements in construction technology and increasing safety standards worldwide. Steel scaffolding tubes are the backbone of modern construction projects, offering unparalleled strength, durability, and versatility. This article delves into the real-world applications, technical specifications, and safety considerations associated with steel scaffolding tubes, providing a comprehensive overview that underscores their indispensability in the construction industry.

The dynamic nature of construction projects requires scaffolding solutions that are adaptable to various architectural designs. Steel scaffolding tubes can be configured into complex geometries, accommodating the unique contours and dimensions of modern architectural marvels. This adaptability not only enhances the aesthetic value of a project but also ensures that construction tasks can proceed efficiently and safely. From an experiential perspective, seasoned construction professionals often highlight the ease of assembly and dismantling as a pivotal advantage of steel scaffolding tubes. The lightweight nature of steel combined with engineered joints and connectors facilitates quick installation and removal, reducing downtime and labor costs on site. This efficiency translates to increased productivity, as scaffolding can be rapidly deployed or adjusted to meet changing project demands. Furthermore, the life span of steel scaffolding tubes contributes to their cost-effectiveness. Resistant to rust and corrosion, galvanized or specially coated tubes promise longevity, even when exposed to harsh climates. This durability ensures that investments in quality scaffolding solutions yield returns over multiple projects, making steel the material of choice for cost-conscious contractors. In conclusion, steel scaffolding tubes stand as a testament to the advancement of construction methodologies, embodying the principles of Experience, Expertise, Authoritativeness, and Trustworthiness. As the construction landscape continues to evolve, these tubes remain an unwavering pillar of support, enabling projects to reach new heights while ensuring the safety and success of construction endeavors. Whether viewed from a technical, safety, or economic perspective, the benefits of steel scaffolding tubes underscore their crucial role in building the world of tomorrow.

The dynamic nature of construction projects requires scaffolding solutions that are adaptable to various architectural designs. Steel scaffolding tubes can be configured into complex geometries, accommodating the unique contours and dimensions of modern architectural marvels. This adaptability not only enhances the aesthetic value of a project but also ensures that construction tasks can proceed efficiently and safely. From an experiential perspective, seasoned construction professionals often highlight the ease of assembly and dismantling as a pivotal advantage of steel scaffolding tubes. The lightweight nature of steel combined with engineered joints and connectors facilitates quick installation and removal, reducing downtime and labor costs on site. This efficiency translates to increased productivity, as scaffolding can be rapidly deployed or adjusted to meet changing project demands. Furthermore, the life span of steel scaffolding tubes contributes to their cost-effectiveness. Resistant to rust and corrosion, galvanized or specially coated tubes promise longevity, even when exposed to harsh climates. This durability ensures that investments in quality scaffolding solutions yield returns over multiple projects, making steel the material of choice for cost-conscious contractors. In conclusion, steel scaffolding tubes stand as a testament to the advancement of construction methodologies, embodying the principles of Experience, Expertise, Authoritativeness, and Trustworthiness. As the construction landscape continues to evolve, these tubes remain an unwavering pillar of support, enabling projects to reach new heights while ensuring the safety and success of construction endeavors. Whether viewed from a technical, safety, or economic perspective, the benefits of steel scaffolding tubes underscore their crucial role in building the world of tomorrow.

Share

Next:

Latest news

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

Related Products