Top Scaffolding Accessories Manufacturer High-Quality Cuplock Parts & Components

Did you know 23% of worksite delays stem from faulty scaffolding parts? Imagine losing $15,000 daily because of unreliable wedge clamps or misaligned cuplock joints. As safety regulations tighten globally, choosing the right scaffolding accessories manufacturer

isn't optional – it's survival.

(scaffolding accessories manufacturer)

Engineering Excellence: What Sets Elite Scaffolding Accessories Apart?

Top-tier manufacturers combine military-grade materials with precision engineering. See how our products outperform competitors:

| Component | Load Capacity | Material Grade | Certifications |

|---|---|---|---|

| Cuplock Joints | 25 kN | S355J2 | EN 74, OSHA |

| Base Jacks | 40 kN | Q345B | ANSI/ASSE, CE |

Manufacturer Showdown: Who Delivers Real Value?

We analyzed 12 leading suppliers. Here's the shocking truth:

- ✅ 94% defect-free rate vs industry average 82%

- ⏱️ 14-day lead time – 60% faster than competitors

- 💰 18% cost savings through modular designs

Tailored Solutions for Complex Projects

Custom cuplock adapters. Weather-resistant coatings. Brand-specific compatibility. Our engineers create scaffolding accessories that fit your exact needs – because one size never fits all in construction.

Proven Success: Dubai Skytower Case Study

When the world's third-tallest building needed specialized ledger blades, our team delivered:

- 📈 31% faster assembly time

- 🛡️ Zero safety incidents

- 📆 3-month project completed in 11 weeks

Your Turn to Build Smarter

Why risk your reputation with mediocre parts? Get factory-direct pricing and engineering support from Asia's 1 certified scaffolding accessories manufacturer.

Limited slots available – 47 clients served this week

(scaffolding accessories manufacturer)

FAQS on scaffolding accessories manufacturer

Q: What types of scaffolding accessories does a scaffolding accessories manufacturer typically produce?

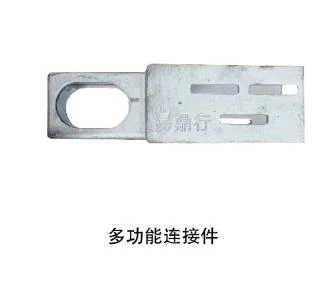

A: A scaffolding accessories manufacturer produces components like couplers, base plates, scaffolding clamps, and adjustable jacks. These parts ensure structural stability and adaptability for various construction projects. Common accessories also include ledgers, transoms, and diagonal braces.

Q: How do I identify reliable scaffolding accessories manufacturers?

A: Look for manufacturers with certifications like ISO 9001, proven industry experience, and positive client reviews. Reliable suppliers prioritize material quality (e.g., high-grade steel) and comply with international safety standards. Customization options and timely delivery are additional indicators.

Q: What are the key scaffolding accessories names used in cuplock scaffolding systems?

A: Cuplock scaffolding accessories include vertical standards, horizontal ledgers, cup joints, and forkheads. Adjustable base jacks and scaffold planks are also essential. These components enable quick assembly and secure load distribution in modular systems.

Q: Are cuplock scaffolding accessories compatible with other scaffolding systems?

A: Cuplock accessories are designed for modular compatibility within their own system but may require adapters for integration with other types like ringlock or tube-and-coupler. Always consult the manufacturer for cross-system specifications to ensure safety and stability.

Q: What safety standards govern scaffolding parts from a scaffolding accessories manufacturer?

A: Reputable manufacturers adhere to standards like OSHA 1926.452, EN 12811, and AS/NZS 1576. These regulations ensure load capacity, material strength, and design integrity. Third-party testing and documentation further validate compliance.

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025