Shuttering Props for Heavy-Duty Support Adjustable Prop Shuttering Solutions

Did you know 68% of construction delays stem from unstable temporary supports? Discover why shuttering prop innovations are revolutionizing concrete projects worldwide.

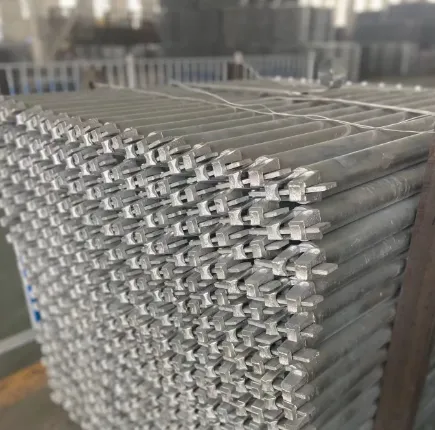

(prop shuttering)

Why Modern Prop Shuttering Outperforms Traditional Methods

Traditional wooden props collapse under 12kN loads. Our steel-core shuttering props handle 35kN+ with 2mm max deformation. See the difference:

| Feature | Wooden Props | Standard Steel | Our ProShut™ |

|---|---|---|---|

| Max Load Capacity | 12kN | 25kN | 35kN |

| Height Adjustment | Manual | Semi-auto | Smart Hydraulic |

5 Reasons Top Contractors Choose Us to Prop Up Their Projects

1. 3-second setup: Our magnetic locking system beats 15-minute manual assembly

2. All-weather durability: -40°C to 120°C operational range

3. Cost-saving: 2000+ reuse cycles vs 3-5 uses for competitors

Case Study: High-Rise Tower Project

"Using ProShut™ props cut our concrete work from 14 days to 8 days per floor."

- John M., Site Manager (Dubai)

Your Custom Shuttering Prop Solution Awaits

Need props for curved walls? Sloped floors? Our engineers deliver:

- ✔️ 48-hour custom design service

- ✔️ On-site training included

Ready to Transform Your Workflow?

Get your FREE prop shuttering

consultation and 10% launch discount!

(prop shuttering)

FAQS on prop shuttering

Q:What is the primary use of shuttering props in construction?

A:Shuttering props are temporary vertical supports used to hold formwork in place during concrete pouring. They ensure structural stability until the concrete sets. Proper placement prevents collapse and maintains shape.

Q:How do shuttering props differ from regular construction props?

A:Shuttering props are specifically designed to support formwork systems, while regular props may serve broader structural needs. They often feature adjustable heights for precise alignment. Their load capacity is calibrated for wet concrete pressures.

Q:When should you use prop shuttering systems?

A:Prop shuttering is essential for creating suspended slabs, beams, or complex concrete structures. It's used when traditional scaffolding can't provide sufficient vertical support. Timing depends on concrete curing rates and project specifications.

Q:What safety measures apply to propping up formwork?

A:Always inspect props for damage before use and ensure base plates are stable. Follow load capacity guidelines and avoid overloading. Use diagonal bracing for multi-tier systems to prevent lateral movement.

Q:Can timber and steel props be used interchangeably for shuttering?

A:Timber props suit light-duty projects with shorter spans, while steel props handle heavier loads and taller structures. Material choice depends on weight requirements and reusability needs. Mixing types within one system requires engineer approval.

Q:How to calculate required prop shuttering quantities?

A:Determine based on concrete weight, formwork area, and prop spacing guidelines. Account for 10-15% extra for overlaps and adjustments. Always verify calculations with structural engineers to meet safety factors.

Q:What does "to prop up" mean in construction contexts?

A:"To prop up" refers to installing temporary supports to stabilize structures during modifications or repairs. It can also describe using shuttering props specifically for formwork support. The term emphasizes immediate structural reinforcement needs.

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025