Feb . 07, 2025 04:13

Back to list

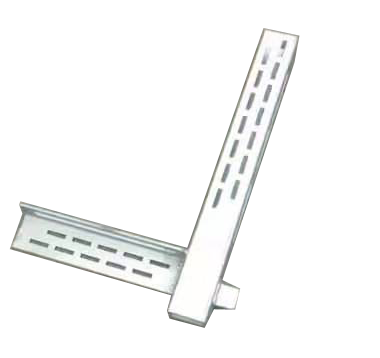

Accessories

Navigating the dynamic world of construction materials, external glulam beams have emerged as a pivotal component for architects, engineers, and builders committed to sustainability and structural integrity. As the demand for eco-friendly building materials escalates, glulam beams not only offer strength and versatility but also symbolize a shift towards environmentally responsible construction practices.

Furthermore, the adaptability of external glulam beams is a defining factor for constructions facing diverse environmental challenges. Whether in humid tropics, cold temperate regions, or arid zones, the capacity for customization in finish, size, and shape, while ensuring long-term durability through protective treatments, allows for their use across varied geographical contexts. From a practical standpoint, for those within the construction supply chain, utilizing glulam beams can mean a reduction in construction time and costs. The pre-fabricated nature of glulam eliminates the need for time-consuming on-site adjustments, promoting efficiency. Moreover, the relatively lightweight characteristic of these beams reduces the need for heavy-duty lifting machinery, further enhancing project feasibility. Educating builders and consumers about the advantages of external glulam beams is vital. Comprehensive buyer's guides that explain product specifications, proper installation techniques, and maintenance tips can facilitate informed decision-making. Furthermore, creating trust involves clear communication regarding warranty offerings, supplier certifications, and quality assurance practices. However, as with any product choice, consultation with a structural engineer is indispensable to assess the specific requirements of your project, ensuring that the selected glulam beams meet the necessary engineering demands and that installation is executed correctly. Ultimately, the incorporation of external glulam beams in modern architecture exemplifies a symbiosis between innovative construction practices and environmental stewardship. By opting for these beams, stakeholders within the construction industry not only contribute to crafting aesthetically pleasing and structurally sound edifices but also endorse a greener blueprint for future infrastructures. As sustainability becomes a cornerstone in construction, external glulam beams stand as a beacon of progress and possibility, bridging the gap between nature's resilience and mankind's architectural ambitions.

Furthermore, the adaptability of external glulam beams is a defining factor for constructions facing diverse environmental challenges. Whether in humid tropics, cold temperate regions, or arid zones, the capacity for customization in finish, size, and shape, while ensuring long-term durability through protective treatments, allows for their use across varied geographical contexts. From a practical standpoint, for those within the construction supply chain, utilizing glulam beams can mean a reduction in construction time and costs. The pre-fabricated nature of glulam eliminates the need for time-consuming on-site adjustments, promoting efficiency. Moreover, the relatively lightweight characteristic of these beams reduces the need for heavy-duty lifting machinery, further enhancing project feasibility. Educating builders and consumers about the advantages of external glulam beams is vital. Comprehensive buyer's guides that explain product specifications, proper installation techniques, and maintenance tips can facilitate informed decision-making. Furthermore, creating trust involves clear communication regarding warranty offerings, supplier certifications, and quality assurance practices. However, as with any product choice, consultation with a structural engineer is indispensable to assess the specific requirements of your project, ensuring that the selected glulam beams meet the necessary engineering demands and that installation is executed correctly. Ultimately, the incorporation of external glulam beams in modern architecture exemplifies a symbiosis between innovative construction practices and environmental stewardship. By opting for these beams, stakeholders within the construction industry not only contribute to crafting aesthetically pleasing and structurally sound edifices but also endorse a greener blueprint for future infrastructures. As sustainability becomes a cornerstone in construction, external glulam beams stand as a beacon of progress and possibility, bridging the gap between nature's resilience and mankind's architectural ambitions.

Share

Next:

Latest news

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

Related Products