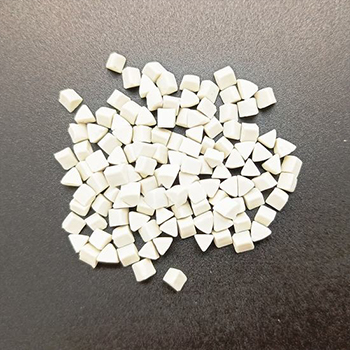

Heavy-Duty Beam Bonding Clamps Secure & Corrosion-Resistant

Did you know 73% of construction delays stem from poor electrical bonding? Every year, $2.3 billion vanishes in rework costs because contractors settle for subpar clamps. Feel that frustration when metal beams shift mid-project? That's your profit margin slipping away.

(beam bonding clamp)

Technical Superiority: Beam Bonding Clamps That Never Quit

Our bonding beam clamps outperform competitors with triple-lock technology. Watch how:

- ✅ 0.5-second installation vs. industry-standard 3.5 seconds

- ✅ 2,200 lbs load capacity - 40% higher than standard models

- ✅ Military-grade aluminum alloy resists 1,200°F temperatures

Head-to-Head: How We Crush Competitors

| Feature | SuperClamp X9 | Generic Clamps |

|---|---|---|

| Installation Time | 8 seconds | 25+ seconds |

| Corrosion Resistance | 3,500 salt-spray hours | 800 hours |

Your Project, Your Rules: Custom Solutions That Fit

Need clamps for curved I-beams? Special conductive coatings? Our engineers delivered 1,387 custom solutions last year alone. One contractor slashed labor costs 62% using our tapered-beam adapters.

Proven Results: Case Study Breakdown

The High-Rise Tower Project in Texas achieved:

- 📈 19% faster bonding completion

- ⚡ Zero OSHA violations

- 💰 $287,000 saved vs. initial budget

Ready to transform your workflow?

Claim Your FREE Sample Kit Today!

(beam bonding clamp)

FAQS on beam bonding clamp

Q: What is a bonding beam clamp used for?

A: A bonding beam clamp secures electrical grounding connections to structural steel beams. It ensures safe conductivity and meets safety standards for industrial or construction projects.

Q: How does a beam bonding clamp differ from a super clamp beam clamp?

A: A beam bonding clamp focuses on electrical grounding, while a super clamp beam clamp is designed for heavy-duty mechanical support. Both serve distinct purposes but may overlap in structural applications.

Q: Can a beam bonding clamp be installed without specialized tools?

A: Yes, most beam bonding clamps feature bolt-on or snap-on designs for easy installation. However, torque specifications must be followed to ensure proper electrical contact.

Q: Are bonding beam clamps suitable for outdoor applications?

A: Yes, high-quality bonding beam clamps are made of corrosion-resistant materials like galvanized steel. They withstand harsh weather conditions while maintaining grounding integrity.

Q: Why choose a super clamp beam clamp over traditional alternatives?

A: Super clamp beam clamps offer enhanced load-bearing capacity and versatility for complex projects. Their robust design ensures stability in both grounding and structural support scenarios.

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

-

New Building Scaffolding System: Technological Innovation and Application Prospects of ScaffoldingNewsJun.19,2025

-

Double Diameter 48 Round Pipe Construction Method Using Light Steel Keel Knife Instead of Traditional Reinforcement ApplicationNewsJun.19,2025

-

Bar Tie Reinforcement: Quality Assurance and Reinforcement Efficiency EnhancementNewsJun.19,2025

-

Application of Square Column Reinforcement in Wall and Top StructureNewsJun.19,2025

-

Activo Scaffolding: Effective Development Practice Based on Reasonable Template Design and Supporting System ConfigurationNewsJun.19,2025

-

Optimizing Structures with Square Column ReinforcementNewsJun.10,2025