Gen . 28, 2025 02:09

Back to list

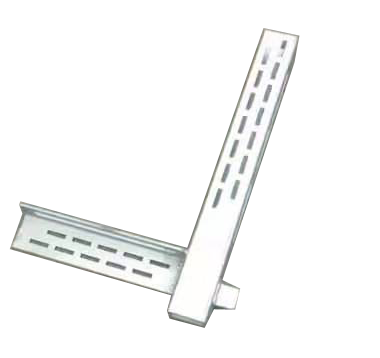

aluminium tilt panel formwork

Aluminium tilt panel formwork has revolutionized the construction industry by providing an efficient, versatile, and environmentally-friendly solution for building concrete structures. This cutting-edge technology is not only redefining the traditional construction processes but is also adding substantial value through its durability and cost-effectiveness. By exploring the practical benefits, industry insights, and real-world applications of aluminium tilt panel formwork, we can understand why it's rapidly becoming the preferred choice for contractors and builders worldwide.

In terms of authority and trustworthiness, the aluminum tilt panel formwork industry is supported by rigorous quality standards and certifications. Manufacturers adhere to international quality assurance protocols, ensuring that every panel produced meets the stringent requirements necessary for safe and effective use in construction. Leading certification bodies regularly audit these processes, reinforcing the reliability of aluminum formwork systems. Consequently, construction companies and project managers can invest with confidence, knowing that they are backed by a tried-and-tested system that aligns with global construction standards. Real-world applications of aluminum tilt panel formwork are abundant and diverse. In urban landscapes, where rapid construction is essential, developers favor this formwork for its speed and efficiency. A case in point is the successful completion of a large-scale residential project in New York, where aluminum formwork was pivotal in achieving a record-breaking build schedule without compromising quality. Meanwhile, in remote or environmentally sensitive areas, the formwork's lightweight nature minimizes its ecological footprint, facilitating sustainable development practices. Looking ahead, the aluminum tilt panel formwork market is poised for growth, with innovations driving further enhancements in product design and functionality. Tech-driven advancements such as digital modelling and precision engineering continue to expand the possibilities, making the formwork more adaptable and efficient than ever before. For instance, integrating automation in the manufacturing process is anticipated to refine the assembly and dismantling phases, cutting down manual intervention and increasing safety on construction sites. In conclusion, aluminium tilt panel formwork represents a quantum leap in construction methodologies. Its lightweight, durable, and versatile nature offers significant advantages that meet the evolving needs of modern architecture and construction. With proven efficiency, sustainability, and compliance with rigorous standards, it stands as a credible and authoritative choice for future construction projects. As the industry continues to innovate, aluminum formwork is likely to play an increasingly pivotal role, paving the way for smarter, faster, and more sustainable building solutions.

In terms of authority and trustworthiness, the aluminum tilt panel formwork industry is supported by rigorous quality standards and certifications. Manufacturers adhere to international quality assurance protocols, ensuring that every panel produced meets the stringent requirements necessary for safe and effective use in construction. Leading certification bodies regularly audit these processes, reinforcing the reliability of aluminum formwork systems. Consequently, construction companies and project managers can invest with confidence, knowing that they are backed by a tried-and-tested system that aligns with global construction standards. Real-world applications of aluminum tilt panel formwork are abundant and diverse. In urban landscapes, where rapid construction is essential, developers favor this formwork for its speed and efficiency. A case in point is the successful completion of a large-scale residential project in New York, where aluminum formwork was pivotal in achieving a record-breaking build schedule without compromising quality. Meanwhile, in remote or environmentally sensitive areas, the formwork's lightweight nature minimizes its ecological footprint, facilitating sustainable development practices. Looking ahead, the aluminum tilt panel formwork market is poised for growth, with innovations driving further enhancements in product design and functionality. Tech-driven advancements such as digital modelling and precision engineering continue to expand the possibilities, making the formwork more adaptable and efficient than ever before. For instance, integrating automation in the manufacturing process is anticipated to refine the assembly and dismantling phases, cutting down manual intervention and increasing safety on construction sites. In conclusion, aluminium tilt panel formwork represents a quantum leap in construction methodologies. Its lightweight, durable, and versatile nature offers significant advantages that meet the evolving needs of modern architecture and construction. With proven efficiency, sustainability, and compliance with rigorous standards, it stands as a credible and authoritative choice for future construction projects. As the industry continues to innovate, aluminum formwork is likely to play an increasingly pivotal role, paving the way for smarter, faster, and more sustainable building solutions.

Share

Next:

Latest news

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

Related Products