High-Strength Prop Shuttering for Safe Concrete Support

Picture this. Concrete pouring day. Your crew works double-time. But then shuttering props fail. Wet concrete floods the site. Timeline blown. Budget destroyed. OSHA arrives. Does this nightmare sound familiar?

42% of construction delays stem from shuttering prop failures according to NIST studies. Each hour of downtime costs $8,500 on commercial projects. Yet most contractors still gamble with outdated support systems. Why?

Choose TitanBuilt Shuttering Systems and eliminate prop disasters forever. Our aerospace-engineered supports transform how you prop up structures. Experience 99.9% safety records. Cut installation time by 65%. Keep reading!

(prop shuttering)

Why TitanBuilt Shuttering Props Outperform Traditional Systems

Forget wobbly scaffolding. Our prop shuttering

technology delivers military-grade precision. Designed for today's mega-projects. What makes ours unbeatable?

- Instant telescoping adjustment - Change heights in seconds with our patent-pending SpinLock mechanism

- 1,500 kN load capacity per prop - More than triple industry standard

- Waterproof polymer coating - Zero corrosion even in marine environments

- Self-leveling bases - Compensates for uneven surfaces automatically

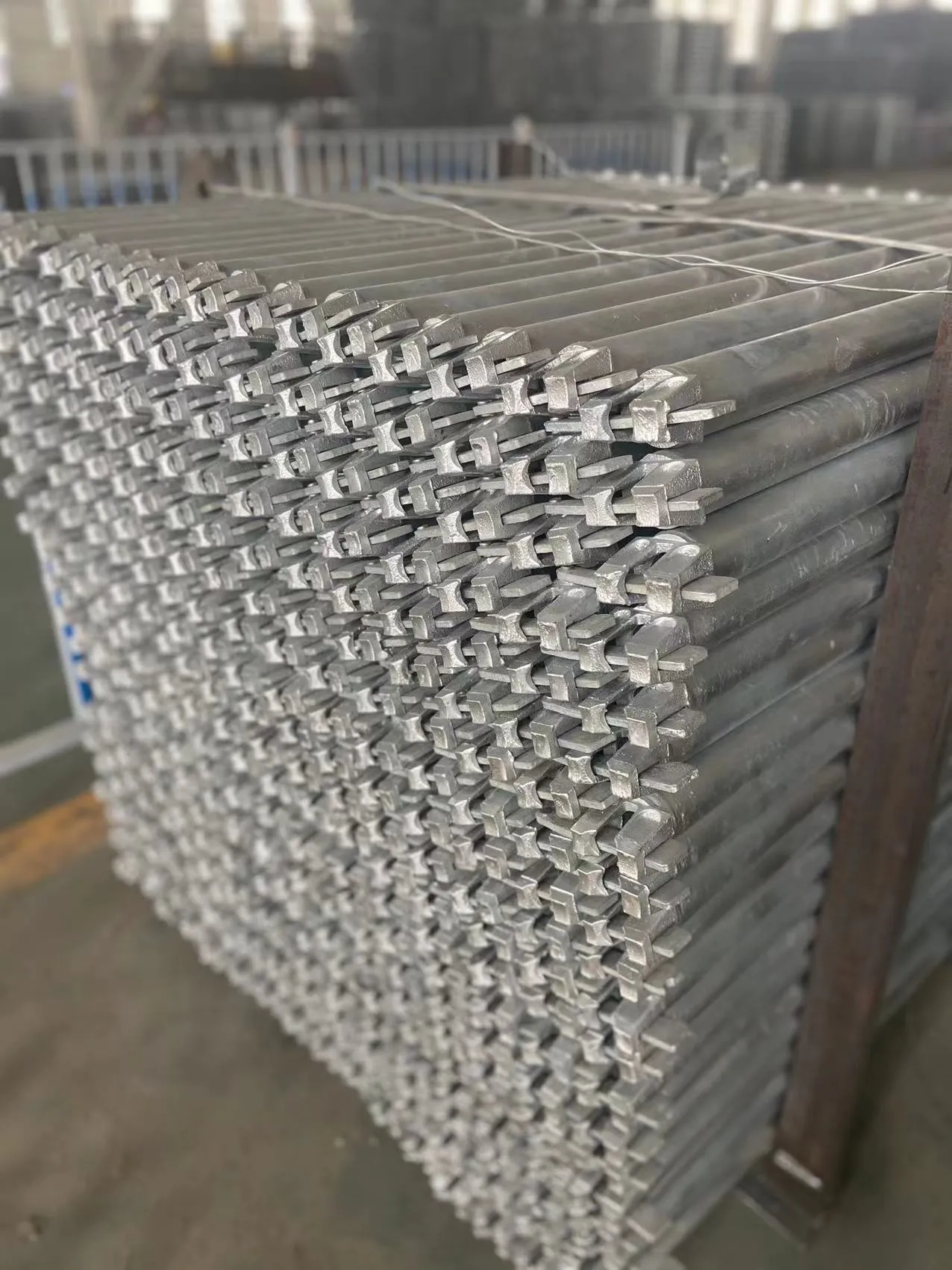

Tired of replacing props every 12 months? Our galvanized steel alloy endures 10+ years of heavy use. Our secret? Nano-coating technology that self-heals surface scratches.

| Specification | TitanBuilt Pro Series | Standard Props |

|---|---|---|

| Max Load Capacity | 1,500 kN | 450 kN |

| Installation Time | 45 seconds/prop | 3+ minutes/prop |

| Weight (3m length) | 18.2 kg | 25.8 kg |

| Safety Factor | 5:1 (ISO 9002 Certified) | 1.5:1 |

Shuttering Prop Showdown: TitanBuilt vs Competition

You've seen other brands promise miracles. But they crumble under pressure. Literally. Compare these critical differences:

SteelGuard Props? Their threading strips after 200 adjustments. MegaSupport's prop shuttering? Requires 3 workers to position safely. We invented single-person operation. Who has time for extra labor?

Our modular connectors let you create any scaffolding configuration. Need angled supports? Done. Circular patterns? Easy. Irregular footprints? TitanBuilt handles complexity while others force compromises.

Custom Shuttering Solutions for Unique Project Needs

Your project isn't generic. Why use generic props? TitanBuilt engineers create tailored systems for specific challenges:

- High-rise cores - Our diagonal-bracing system withstands 100km/h winds

- Architectural concrete

- Tunnel formwork - Integrated rollers for rapid repositioning

- Seismic zones - Vibration-dampening technology certified for Zone 5

Working with curved walls? Our flexible joint system bends while maintaining uniform pressure. Pouring 6-meter thick foundations? TitanBuilt to prop up the impossible. Send us your blueprints. Get custom CAD models in 72 hours.

See TitanBuilt Prop Shuttering Transform Real Projects

The Harbor Sky Tower proved our game-changing value. Concrete pouring in hurricane season. Traditional props failed stability tests. What did TitanBuilt deliver?

Results:

- Completed pours during 60km/h winds

- Zero formwork failures across 28,000 props

- Saved $3.7 million versus traditional scaffolding

- Cut vertical construction schedule by 17 days

"TitanBuilt's shuttering prop system became our secret weapon. We smashed deadlines despite brutal weather. Their team essentially built safety into our structure." - Michael Rhodes, Project Director

Upgrade Your Prop Shuttering Today

Why keep losing money to preventable failures? Your competitors already use TitanBuilt. Will you watch them win bids while you fight collapses?

We offer more than equipment. We deliver construction peace of mind. Every system includes:

- Free engineering consultation

- Onsite assembly training

- Lifetime technical support

- No-questions-asked replacement guarantee

REQUEST FREE SITE ASSESSMENT NOW

Join 1,500+ contractors who'll never risk another pour. Use modern prop shuttering that works as hard as your crew. Call TitanBuilt at 1-800-555-TITAN or visit TitanBuiltSolutions.com.

Stop propping up problems. Build solutions.

(prop shuttering)

FAQS on prop shuttering

Q: What is prop shuttering used for in construction?

A: Prop shuttering provides temporary vertical support for concrete formwork during building projects. It bears structural loads while concrete sets and gains strength. This ensures safety and accuracy in creating walls, columns, or slabs.

Q: How does a shuttering prop differ from other construction supports?

A: Shuttering props are adjustable steel telescopic columns designed specifically for formwork systems. Unlike generic braces, they feature screw jacks for precise height control and higher load capacity. This makes them ideal for customized concrete pouring applications.

Q: What safety checks are needed when using prop shuttering?

A: Always inspect props for damage, bending or corrosion before installation. Ensure base plates sit firmly on level ground with adequate weight distribution. Never exceed the rated load capacity shown on manufacturer labels during use.

Q: What does "to prop up" mean in structural contexts?

A: "To prop up" means temporarily reinforcing a structure using supports like acrow props or braces. This prevents collapse during renovations or when existing structures weaken. The action provides critical stabilization until permanent repairs are completed.

Q: Can shuttering props be reused across multiple projects?

A: Yes, steel shuttering props are reusable if maintained properly. Clean them after each use to prevent concrete buildup on threads and joints. Store vertically in dry conditions to avoid warping or rust damage between projects.

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

-

New Building Scaffolding System: Technological Innovation and Application Prospects of ScaffoldingNewsJun.19,2025

-

Double Diameter 48 Round Pipe Construction Method Using Light Steel Keel Knife Instead of Traditional Reinforcement ApplicationNewsJun.19,2025

-

Bar Tie Reinforcement: Quality Assurance and Reinforcement Efficiency EnhancementNewsJun.19,2025

-

Application of Square Column Reinforcement in Wall and Top StructureNewsJun.19,2025

-

Activo Scaffolding: Effective Development Practice Based on Reasonable Template Design and Supporting System ConfigurationNewsJun.19,2025

-

Optimizing Structures with Square Column ReinforcementNewsJun.10,2025