फरवरी . 03, 2025 01:21

Back to list

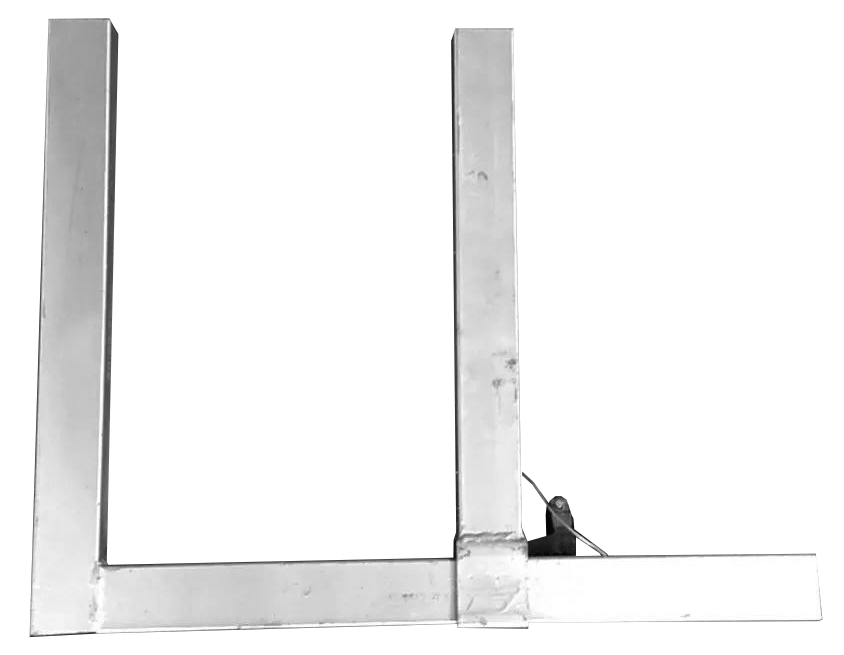

column plywood formwork

Column plywood formwork has long emerged as a staple in the construction industry, particularly for casting concrete columns. Its significance lies in the amalgamation of time-tested practices and modern engineering to meet the evolving demands of construction projects. Delving into this topic with an understanding of experience, expertise, authoritativeness, and trustworthiness provides clarity on why this formwork continues to reign supreme among builders and architects.

Evaluated through the lens of authoritativeness, the choice of column plywood formwork is often backed by industry leaders' recommendations and professional guidelines. Reputable industry bodies have conducted extensive research, resulting in standards that reinforce its use as a reliable material for form casting. This broad endorsement is a testament to the material's ability to meet stringent performance benchmarks in actual construction environments. Trustworthiness stems from real-world performance. The track record of successful construction projects utilizing column plywood formwork substantiates claims of its efficacy. Builders with years of experience vouch for its ability to maintain structural form during the curing process, minimizing imperfections in the finished concrete columns. This reliability is paramount, especially when client satisfaction and safety are at the forefront. Furthermore, innovations in the production and treatment of plywood continue to reinforce its status. Modern sustainable practices in sourcing wood for plywood reduce environmental impact, aligning construction practices with ecological mandates. Manufacturers now emphasize certified sustainable sources, ensuring that the formwork doesn't just support the infrastructure but also complements global sustainability goals. In conclusion, column plywood formwork stands out as a quintessential element in construction due to its tangible benefits that align with correctness, efficiency, and sustainability. While it offers technical advantages like flexibility and ease of handling, its legacy is etched deeper, backed by decades of practical use and validation by industry authorities. As construction continues to evolve, embracing materials that balance traditional knowledge with modern demands remains vital, and column plywood formwork exemplifies this harmony. For architects, engineers, and builders aiming to deliver robust, efficient, and sustainable projects, it stands as a tried and tested path to achieving exemplary results.

Evaluated through the lens of authoritativeness, the choice of column plywood formwork is often backed by industry leaders' recommendations and professional guidelines. Reputable industry bodies have conducted extensive research, resulting in standards that reinforce its use as a reliable material for form casting. This broad endorsement is a testament to the material's ability to meet stringent performance benchmarks in actual construction environments. Trustworthiness stems from real-world performance. The track record of successful construction projects utilizing column plywood formwork substantiates claims of its efficacy. Builders with years of experience vouch for its ability to maintain structural form during the curing process, minimizing imperfections in the finished concrete columns. This reliability is paramount, especially when client satisfaction and safety are at the forefront. Furthermore, innovations in the production and treatment of plywood continue to reinforce its status. Modern sustainable practices in sourcing wood for plywood reduce environmental impact, aligning construction practices with ecological mandates. Manufacturers now emphasize certified sustainable sources, ensuring that the formwork doesn't just support the infrastructure but also complements global sustainability goals. In conclusion, column plywood formwork stands out as a quintessential element in construction due to its tangible benefits that align with correctness, efficiency, and sustainability. While it offers technical advantages like flexibility and ease of handling, its legacy is etched deeper, backed by decades of practical use and validation by industry authorities. As construction continues to evolve, embracing materials that balance traditional knowledge with modern demands remains vital, and column plywood formwork exemplifies this harmony. For architects, engineers, and builders aiming to deliver robust, efficient, and sustainable projects, it stands as a tried and tested path to achieving exemplary results.

Share

Next:

Latest news

-

Top Scaffolding Solutions for Every Construction ProjectNewsApr.21,2025

-

Scaffolding Solutions for Every ProjectNewsApr.21,2025

-

Innovative Construction Solutions for a Stronger FutureNewsApr.21,2025

-

Essential Steel Keel Solutions for Maximum Protection and PerformanceNewsApr.21,2025

-

Building a solid foundation: The importance of high-quality concrete reinforcement accessoriesNewsApr.21,2025

-

Effective Reinforcement for Stronger StructuresNewsApr.21,2025

-

The Essential Role of Timber and Steel in Modern ConstructionNewsMar.10,2025

Related Products