जनवरी . 13, 2025 10:04

Back to list

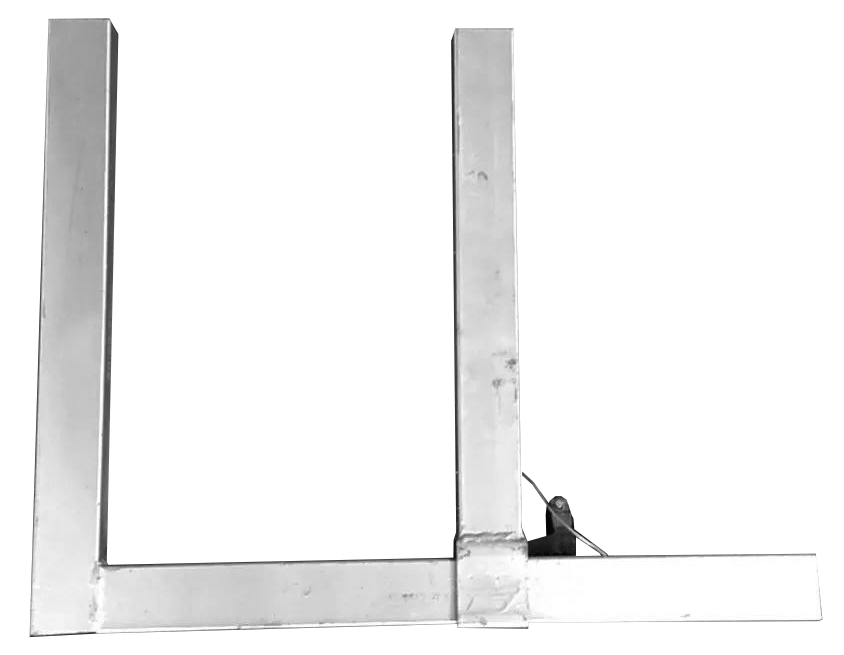

aluminium scaffolding for sale

Aluminium formwork panels have revolutionized the construction industry, offering an innovative solution that combines efficiency, durability, and cost-effectiveness. As the construction world steadily moves towards quicker completion times and sustainable practices, aluminium formwork stands out as an ideal choice for builders and contractors who aim for excellence.

Aluminium formwork is also a cornerstone of sustainable construction practices. The panels' reusability contributes directly to reducing waste, a critical component of environmentally friendly building methods. Moreover, aluminium is highly recyclable, aligning with the industry's move towards a circular economy. This sustainability factor elevates the profile of any construction project, providing added value to developers and positively impacting the community. Authority figures within the construction sector, including engineers and building inspectors, often recommend aluminium formwork systems for their contribution to improved safety on site. The preciseness of formwork assembly eliminates common errors associated with using traditional methods, leading to fewer incidents and enhancing the overall safety of the construction environment. Trustworthiness is naturally embedded in the reputation of aluminium formwork, as seen from years of successful implementation in diverse projects worldwide. Manufacturing standards for these panels are rigorous, ensuring that they meet or exceed international safety and quality benchmarks. When products undergo such stringent evaluation, it affirms the reliability that builders and contractors expect. In conclusion, aluminium formwork panels are at the forefront of modern construction techniques. With their unmatched efficiency, adaptability, sustainability, and safety, these panels are indispensable in achieving unparalleled construction quality. For those in the industry looking to innovate and stay ahead of the curve, investing in aluminium formwork systems is a prudent step towards excellence and future-ready construction practices.

Aluminium formwork is also a cornerstone of sustainable construction practices. The panels' reusability contributes directly to reducing waste, a critical component of environmentally friendly building methods. Moreover, aluminium is highly recyclable, aligning with the industry's move towards a circular economy. This sustainability factor elevates the profile of any construction project, providing added value to developers and positively impacting the community. Authority figures within the construction sector, including engineers and building inspectors, often recommend aluminium formwork systems for their contribution to improved safety on site. The preciseness of formwork assembly eliminates common errors associated with using traditional methods, leading to fewer incidents and enhancing the overall safety of the construction environment. Trustworthiness is naturally embedded in the reputation of aluminium formwork, as seen from years of successful implementation in diverse projects worldwide. Manufacturing standards for these panels are rigorous, ensuring that they meet or exceed international safety and quality benchmarks. When products undergo such stringent evaluation, it affirms the reliability that builders and contractors expect. In conclusion, aluminium formwork panels are at the forefront of modern construction techniques. With their unmatched efficiency, adaptability, sustainability, and safety, these panels are indispensable in achieving unparalleled construction quality. For those in the industry looking to innovate and stay ahead of the curve, investing in aluminium formwork systems is a prudent step towards excellence and future-ready construction practices.

Share

Next:

Latest news

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

Related Products