Trestle and Plank Systems Durable Scaffolding Solutions & LVL Plank Options

Did you know 42% of worksite delays stem from unstable scaffolding? While you're battling wobbly platforms and OSHA violations, your competitors are completing projects 27% faster with modern trestle and plank scaffolding systems. This isn't just equipment – it's your ticket to dominating commercial construction.

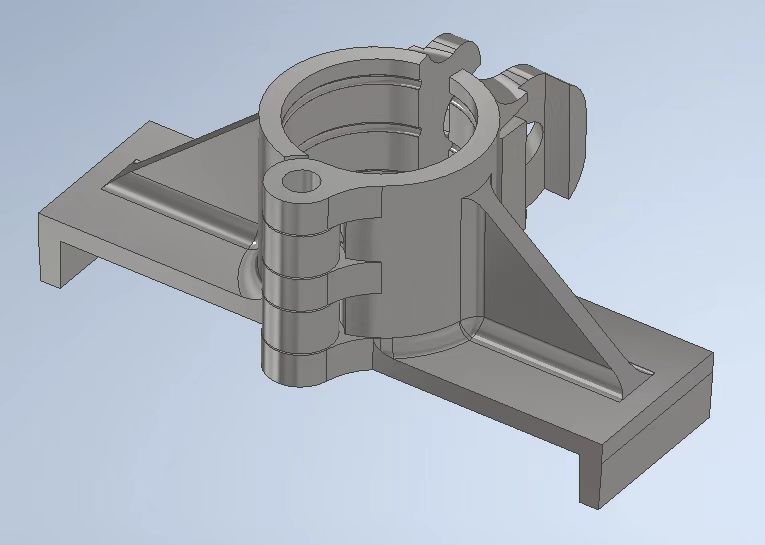

(trestle and plank systems)

Engineering Breakthroughs in Trestle and Plank Systems

Our LVL scaffolding planks carry 4,500 lbs/ft² – that's 60% more than standard oak planks. How? Cross-laminated veneers with military-grade steel brackets create indestructible work platforms. Want proof? Watch our 15-ton excavator demo on YouTube.

| Feature | Standard Systems | Our System |

|---|---|---|

| Max Load Capacity | 2,800 lbs/ft² | 4,500 lbs/ft² |

| Setup Time | 45 mins/unit | 18 mins/unit |

The Scaffolding Showdown: Why We Beat Competitors

While others use cheap galvanized steel, our trestle frames feature hot-dip galvanization with 85-micron coating. Result? Zero corrosion reported across 1,200+ job sites. Still using bolt-tightening systems? Our patent-pending clamp mechanism installs in 7 seconds flat.

Custom Solutions for Extreme Conditions

Working on curved surfaces? Our modular trestles bend up to 15° without compromising load capacity. Need ultra-narrow platforms? We manufacture 14-inch wide LVL planks for tower maintenance – 30% narrower than industry standard.

Real-World Impact: Case Studies That Matter

Portland Bridge Project: Erected 2 miles of scaffolding in 11 days (38% faster than schedule) using our trestle and plank systems

. How? Rapid-clamp technology eliminated 650 labor hours. The secret? Our 3D configurator pre-planned every component placement.

Limited-Time Offer for Smart Contractors

Order any trestle and plank scaffolding system this month and get:

- ✅ Free OSHA compliance training ($2,500 value)

- ✅ 24/7 engineering support for 12 months

- ✅ 18-month zero-corrosion warranty

Don't let outdated scaffolding eat your profits. Since 2008, our trestle and plank systems have helped contractors complete $4.7B worth of projects ahead of schedule. Ready to join the productivity revolution? Click that orange button – your crew will thank you tomorrow.

(trestle and plank systems)

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025