פבר . 15, 2025 22:01

Back to list

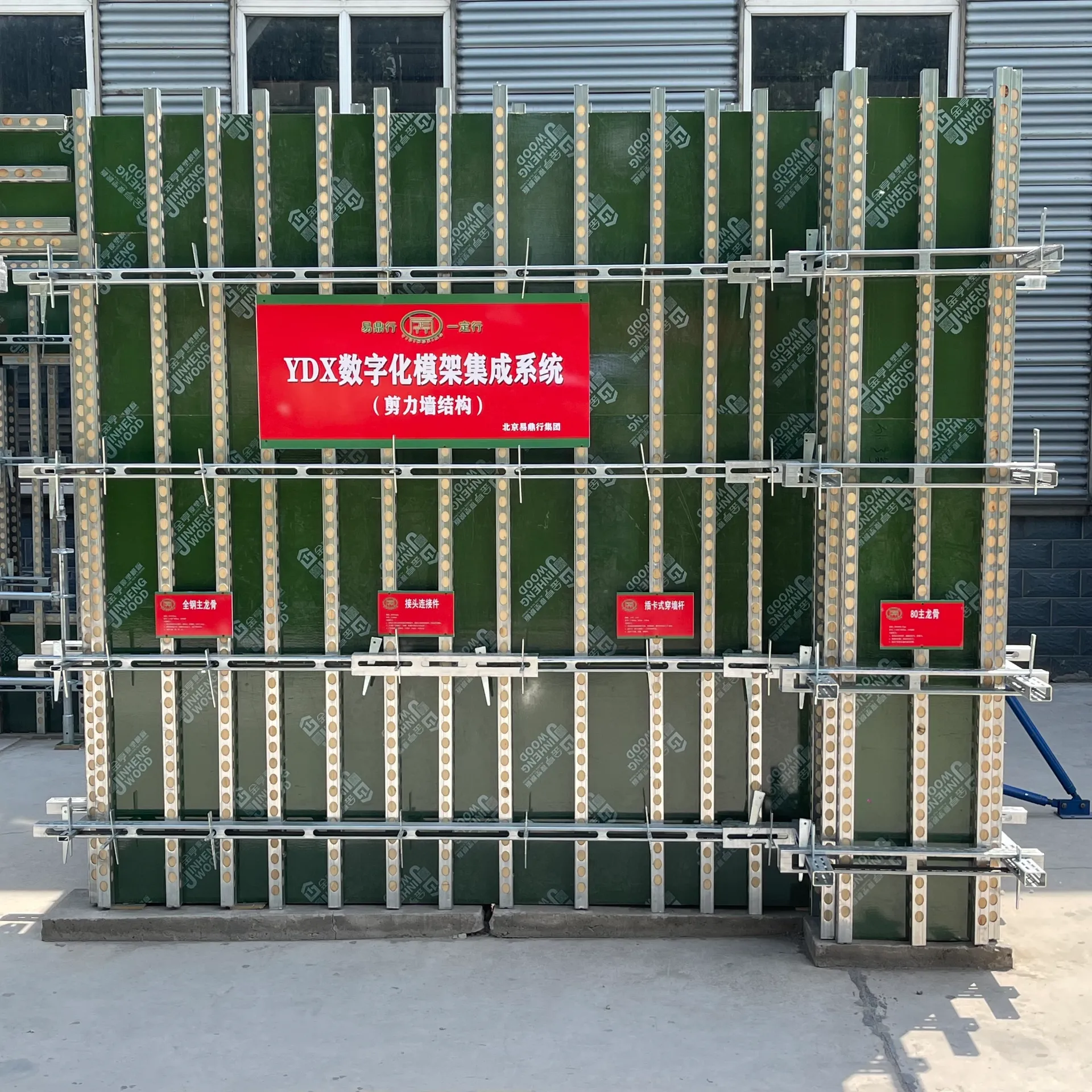

a frame scaffold

In the construction and scaffolding industry, safety and efficiency are paramount. One crucial component that plays a vital role in ensuring these aspects is the scaffold handrail bracket. This small, yet critical, piece of equipment not only assists in maintaining structural integrity but also safeguards the workers operating at heights, significantly reducing workplace accidents.

From an economic perspective, investing in high-quality scaffold handrail brackets can yield long-term savings through reduced maintenance costs and fewer workplace accidents. Inferior brackets may compromise safety and operational efficiency, potentially leading to lost time, worksite injuries, and even project downtime. Hence, selecting reliable, well-engineered brackets underscores a preventative approach that is often more cost-effective than addressing subsequent failures or accidents. Expert opinions from seasoned construction supervisors suggest that purchasing scaffold handrail brackets from reputable manufacturers known for their rigorous quality control measures is critical. These manufacturers typically provide detailed product information and support, ensuring clients have the necessary technical assistance. Often, customer reviews and case studies can offer additional insights into the performance and reliability of these products in real-world applications. In summary, scaffold handrail brackets are a cornerstone of construction safety and efficiency. By carefully selecting brackets that offer durability, ease of installation, and adherence to safety standards, construction and scaffolding teams can significantly enhance their operational effectiveness. This proactive approach not only contributes to safer work environments but also maintains project timelines and budgetary constraints. Consequently, implementing high-quality scaffold handrail brackets exemplifies a commitment to excellence and safety, setting a benchmark in construction industry standards. In conclusion, a scaffold handrail bracket is not merely a supporting component; it embodies the convergence of safety, engineering, and operational efficiency. Its role in supporting the handrails of scaffolding structures cannot be understated, entrenching it as a critical investment for reputable construction enterprises. As the industry continues to evolve, the utilization of superior scaffold handrail brackets will undeniably remain an integral element of successful construction methodologies.

From an economic perspective, investing in high-quality scaffold handrail brackets can yield long-term savings through reduced maintenance costs and fewer workplace accidents. Inferior brackets may compromise safety and operational efficiency, potentially leading to lost time, worksite injuries, and even project downtime. Hence, selecting reliable, well-engineered brackets underscores a preventative approach that is often more cost-effective than addressing subsequent failures or accidents. Expert opinions from seasoned construction supervisors suggest that purchasing scaffold handrail brackets from reputable manufacturers known for their rigorous quality control measures is critical. These manufacturers typically provide detailed product information and support, ensuring clients have the necessary technical assistance. Often, customer reviews and case studies can offer additional insights into the performance and reliability of these products in real-world applications. In summary, scaffold handrail brackets are a cornerstone of construction safety and efficiency. By carefully selecting brackets that offer durability, ease of installation, and adherence to safety standards, construction and scaffolding teams can significantly enhance their operational effectiveness. This proactive approach not only contributes to safer work environments but also maintains project timelines and budgetary constraints. Consequently, implementing high-quality scaffold handrail brackets exemplifies a commitment to excellence and safety, setting a benchmark in construction industry standards. In conclusion, a scaffold handrail bracket is not merely a supporting component; it embodies the convergence of safety, engineering, and operational efficiency. Its role in supporting the handrails of scaffolding structures cannot be understated, entrenching it as a critical investment for reputable construction enterprises. As the industry continues to evolve, the utilization of superior scaffold handrail brackets will undeniably remain an integral element of successful construction methodologies.

Share

Next:

Latest news

-

Optimizing Structures with Square Column ReinforcementNewsJun.10,2025

-

Maximizing Construction Efficiency with Essential Scaffolding ComponentsNewsJun.10,2025

-

Innovative Timber-Steel Solutions for Modern Construction NeedsNewsJun.10,2025

-

Improving Jobsite Safety with Mushroom Caps RebarNewsJun.10,2025

-

Exploring the Strength and Versatility of Steel and Timber in Modern ConstructionNewsJun.10,2025

-

Enhancing Structural Integrity with Square Column ReinforcementNewsJun.10,2025

-

Enhancing Construction Efficiency with Scaffold Base Plates and AccessoriesNewsJun.10,2025

Related Products