Precise Concrete Cover for Rebar: Maximize Durability

The Critical Role of Concrete Cover for Rebar in Structural Integrity

In modern construction, the durability and longevity of reinforced concrete structures are paramount. A fundamental element ensuring this is the adequate concrete cover for rebar. This protective layer of concrete surrounding the steel reinforcement bars is crucial for preventing corrosion, ensuring fire resistance, and allowing the composite action between concrete and steel. Without proper cover, the structural integrity of buildings, bridges, and other infrastructure would be severely compromised, leading to costly repairs and potential safety hazards. Our range of accessories, including precision-engineered spacers, ensures optimal cover reinforcement.

Beyond basic protection, understanding the nuances of concrete cover for rebar involves considering environmental factors, load requirements, and specific industry standards. The proper positioning of reinforcing bars, facilitated by specialized reinforcing bar positioners, directly influences the effectiveness of this protective layer. Our commitment to providing high-quality solutions stems from a deep understanding of these engineering principles, ensuring that every structure built with our accessories meets the highest benchmarks of performance and safety.

Industry Trends and Market Dynamics for Cover Reinforcement

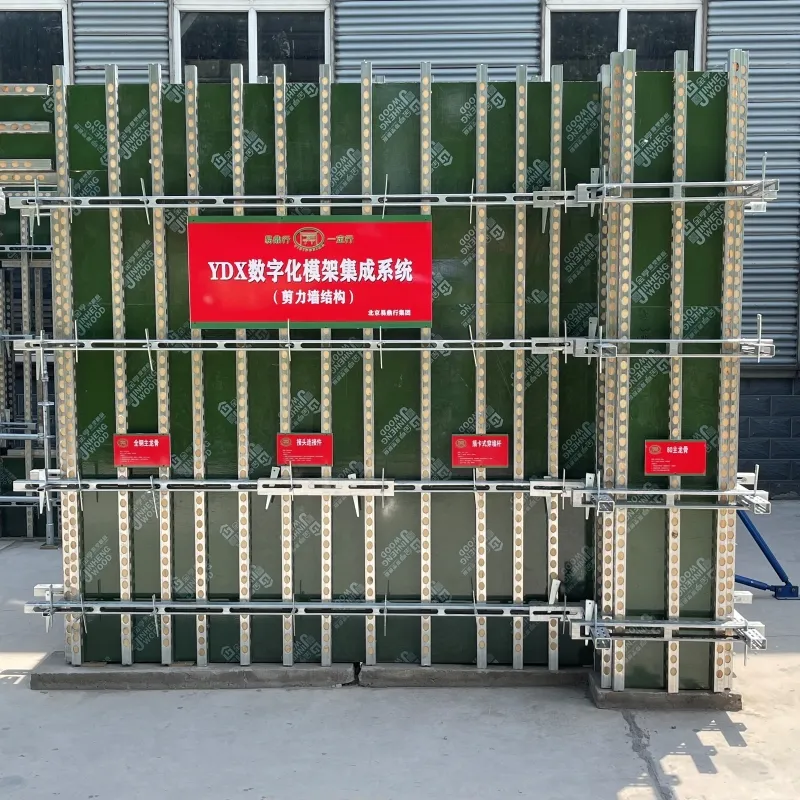

The global construction industry is increasingly focused on sustainable and resilient infrastructure, driving significant trends in the demand for precise cover reinforcement solutions. With urbanization and infrastructure development accelerating, especially in emerging economies, the market for products like concrete spacers and reinforcing bar positioners is experiencing steady growth. Strict building codes and standards, such as those from ACI (American Concrete Institute) and Eurocode, mandate specific cover depths, pushing engineers and contractors to adopt reliable and high-performance accessories. The push for extended service life of structures, particularly in corrosive environments like coastal areas or those exposed to de-icing salts, further emphasizes the importance of optimal concrete cover for rebar.

Technological advancements are also influencing this sector, with the introduction of automated rebar tying machines and prefabrication techniques requiring more standardized and robust concrete spacers. The integration of Building Information Modeling (BIM) in project planning often includes precise detailing of reinforcement and cover, highlighting the need for accurate and high-quality accessories. While specialized components like `slotted angle steel` and `rack slotted angle` serve different but equally vital roles in structural framing and support systems, the fundamental requirement for protective concrete cover remains a universal constant across diverse construction projects.

Technical Parameters and Specifications of Concrete Spacers

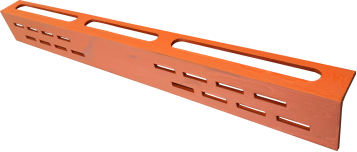

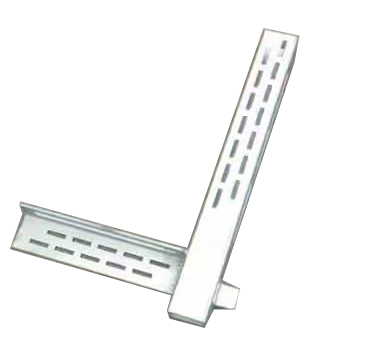

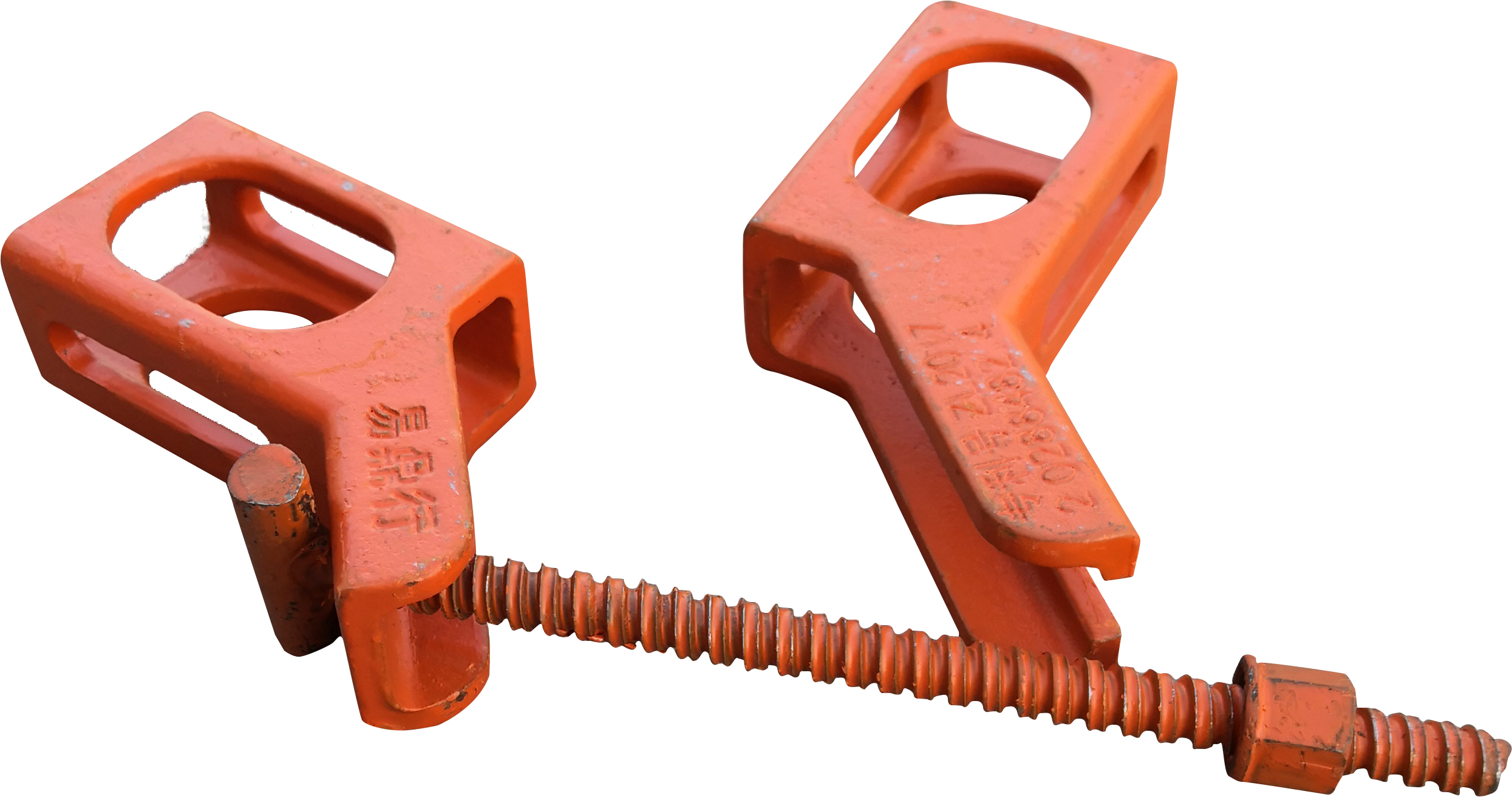

Selecting the appropriate concrete cover for rebar involves understanding critical technical parameters that dictate performance and suitability for specific applications. These parameters ensure the spacer can withstand construction loads, resist environmental degradation, and provide the exact cover depth required by design specifications. Key considerations include the material composition, compressive strength, design geometry (e.g., chair, wheel, bar, block), and the specific cover height it provides.

Here's a general overview of common technical parameters for various types of reinforcing bar positioners:

| Parameter | Plastic Spacers (PVC/HDPE) | Fiber Cement Spacers | Concrete Block Spacers |

|---|---|---|---|

| Material Composition | Recycled/Virgin PVC, HDPE. | Cement, sand, aggregates, cellulose fibers. | High-strength concrete, typically with polypropylene fibers. |

| Compressive Strength | Typically 3-5 kN (depending on design). | > 60 MPa (matching concrete strength). | > 50 MPa (matching concrete strength). |

| Cover Height Range | 15mm - 75mm (common sizes). | 15mm - 100mm+. | 25mm - 100mm+. |

| Durability / Lifespan | Excellent chemical resistance, UV stability varies. | Matches concrete lifespan, excellent chemical/fire resistance. | Matches concrete lifespan, excellent chemical/fire resistance. |

| Bonding with Concrete | Minimal mechanical bond, relies on formwork. | Excellent chemical and mechanical bond, minimal cracking risk. | Excellent chemical and mechanical bond, minimal cracking risk. |

| Temperature Range | -20°C to +80°C. | -40°C to +400°C (fire resistant). | -40°C to +400°C (fire resistant). |

These parameters are critical for structural engineers and contractors to specify the right accessory, ensuring the designed cover reinforcement is achieved and maintained throughout the lifespan of the structure. Our products are designed and tested to meet or exceed these stringent requirements, providing confidence in every application.

Manufacturing Process of Concrete Cover Spacers

The production of reliable concrete cover for rebar involves a meticulous process to ensure uniformity, strength, and precise dimensions. While specific methods vary by material, the general workflow emphasizes quality control at every stage. For plastic spacers, the primary manufacturing process is injection molding. High-quality virgin or recycled polymers (like PVC or HDPE) are melted and injected into precision-machined molds under high pressure. This process allows for complex geometries, consistent dimensions, and efficient mass production. Cooling and demolding complete the cycle, after which products undergo visual inspection and dimension checks.

Fiber cement and concrete spacers, on the other hand, typically utilize vibration casting or pressing techniques. A carefully proportioned mix of cement, fine aggregates, water, and often cellulose or polypropylene fibers is prepared. This mix is then poured or pressed into molds, and vibration is applied to ensure full compaction and eliminate air voids, leading to high-density, high-strength products. After initial setting, the spacers undergo a curing process, often in controlled humidity and temperature environments, to achieve their final design strength. This process is critical for developing the compressive strength and durability required for demanding construction environments.

Throughout both processes, stringent quality control measures are in place. This includes raw material inspection, in-process dimensional checks, and final product testing for compressive strength, impact resistance, and precise cover height. Adherence to international standards like ISO 9001 for quality management and relevant ASTM or EN standards for material properties and performance is non-negotiable, ensuring every reinforcing bar positioner contributes effectively to the structural integrity and longevity of concrete elements. The typical service life of these high-quality spacers is designed to match or exceed that of the concrete structure itself, often ranging from 50 to 100 years or more, depending on environmental conditions and product material.

Technical Advantages and Performance Benefits

The deployment of well-designed concrete cover for rebar offers a multitude of technical advantages that directly impact the performance and lifespan of concrete structures. Foremost among these is superior corrosion protection for the reinforcement steel. By maintaining a uniform and adequate concrete cover, the rebar is shielded from aggressive environmental agents like chlorides, carbon dioxide, and moisture, which are primary catalysts for steel corrosion. This barrier effect significantly extends the service life of the structure, reducing maintenance costs and ensuring long-term structural safety.

Another critical advantage is enhanced fire resistance. Concrete itself acts as an excellent thermal insulator. When the reinforcing steel is adequately covered, it remains protected from high temperatures during a fire, delaying the loss of its strength and ductility. This is vital for maintaining the structural integrity of a building during a fire event, providing valuable evacuation time and minimizing collapse risk. Products designed for optimal cover reinforcement are integral to achieving specified fire ratings for concrete elements.

Furthermore, precise `reinforcing bar positioners` ensure that the rebar is correctly placed, optimizing the composite action between steel and concrete. This proper positioning guarantees that the designed structural capacity (e.g., flexural strength, shear strength) is achieved, as the stress transfer between the two materials relies heavily on accurate bar location. In terms of efficiency, using high-quality spacers streamlines the rebar fixing process, saving time and labor on site, which contributes to overall project efficiency and cost savings. Unlike `slotted angle steel` or `rack slotted angle` which provide structural support or shelving, concrete spacers directly enhance the performance of the concrete itself, making them indispensable components for resilient and durable construction.

Versatile Application Scenarios

The application of concrete cover for rebar is pervasive across virtually all sectors of the construction industry, underpinning the integrity of diverse structures. From residential buildings to monumental infrastructure projects, the necessity of accurate reinforcing bar positioners remains constant. In high-rise commercial and residential buildings, these accessories ensure the durability of load-bearing columns, beams, and slabs, critical for safety and long-term performance in urban environments.

In large-scale infrastructure projects such as bridges, tunnels, and highways, where structures are exposed to harsh environmental conditions, precise cover reinforcement is paramount to resist corrosion from de-icing salts, marine environments, and continuous heavy loads. Similarly, in water treatment facilities and drainage systems, where concrete is constantly exposed to moisture and aggressive chemicals, robust concrete cover is essential for preventing premature deterioration and ensuring system longevity. The petrochemical and metallurgy sectors also rely on reinforced concrete for critical structures, where excellent fire resistance and chemical attack resistance, facilitated by precise concrete cover, are non-negotiable.

Beyond these, specialized applications include precast concrete manufacturing, where automated processes demand consistently accurate spacers, and marine structures like jetties and offshore platforms, requiring maximum protection against chloride ingress. Even in less demanding applications, like general paving or foundation work, maintaining adequate concrete cover for rebar ensures uniformity and aesthetic quality. The adaptability of our spacer solutions allows them to be seamlessly integrated into various construction methodologies, providing essential support for critical structural elements.

Comparative Analysis and Selection Criteria

When selecting the ideal concrete cover for rebar, contractors and engineers often weigh the benefits of different types of spacers and the reliability of manufacturers. While direct manufacturer comparisons require specific product data, we can outline key considerations when evaluating options for `reinforcing bar positioners` and `cover reinforcement`.

- Material Compatibility: Fiber cement or concrete spacers offer excellent compatibility with the surrounding concrete, minimizing differential thermal expansion and potential for cracking. Plastic spacers are cost-effective and easy to handle but may have limitations in high-temperature or fire-rated applications.

- Load Bearing Capacity: High-strength spacers are essential for heavy rebar cages or when subjected to significant foot traffic during construction. This is where robust concrete or fiber cement options often excel.

- Exposure Conditions: For aggressive environments (e.g., marine, chemical plants), spacers must possess inherent corrosion resistance and low permeability. Fiber cement spacers generally perform better in such scenarios than some types of plastic.

- Installation Ease and Stability: While plastic wheel spacers are quick to install on vertical bars, bar-type or block spacers provide superior stability for horizontal applications and heavier reinforcement.

- Cost-Effectiveness: Initial cost, labor savings, and long-term performance must be balanced. While plastic spacers might have lower unit costs, their suitability for critical applications needs careful evaluation.

Our expertise in `cover reinforcement` allows us to guide clients through these selection criteria, recommending optimal solutions based on project specifics, budget constraints, and long-term durability goals. We emphasize not just product features but also their performance in real-world scenarios.

Custom Solutions and Tailored Cover Reinforcement

Not all construction projects fit standard specifications, particularly large-scale infrastructure or highly specialized industrial facilities. Recognizing this, we offer bespoke solutions for concrete cover for rebar, working closely with clients to meet unique structural, environmental, or logistical challenges. This might involve designing custom reinforcing bar positioners with specific cover heights, unique geometries for complex reinforcement cages, or specialized materials for extreme conditions such as high temperatures or aggressive chemical exposure.

Our process for custom `cover reinforcement` solutions begins with a detailed consultation to understand the project's precise requirements, including structural drawings, environmental conditions, and construction methodologies. Our engineering team then leverages advanced design tools and material science expertise to develop prototypes and conduct rigorous testing to ensure performance. This collaborative approach ensures that the customized concrete cover for rebar not only meets but exceeds project-specific demands, preventing future issues and ensuring long-term structural integrity.

Whether it's for unique formwork systems, specialized rebar configurations, or demanding environmental exposure, our capacity for custom solutions ensures that every project achieves optimal `cover reinforcement`, minimizing risks and maximizing durability. Our service goes beyond off-the-shelf products, offering true partnership in complex construction ventures.

Application Cases and Client Success Stories

Our `reinforcing bar positioners` and `cover reinforcement` solutions have been integral to the success of numerous projects across diverse industries, validating their performance and reliability in real-world applications. For instance, in a major coastal bridge construction project, our high-strength fiber cement spacers were chosen for their superior resistance to chloride ingress, ensuring the long-term durability of the bridge in a saline environment. The precise placement capabilities of our products were critical for maintaining the specified concrete cover for rebar, which was a key design parameter for mitigating corrosion risks.

Another notable case involves a large industrial complex in a petrochemical facility, where fire resistance and chemical stability were paramount. Our specialized concrete spacers, designed to withstand extreme temperatures and corrosive substances, were deployed in critical structural elements. The client reported significant confidence in the enhanced safety and longevity provided by the consistent `cover reinforcement`. This project underscored the importance of selecting not just any spacer, but one engineered for the specific demands of the application.

In a high-density urban development featuring multiple high-rise towers, the efficiency of installation and precision of concrete cover for rebar were key factors. Our plastic wheel and bar spacers facilitated rapid and accurate rebar placement for both vertical and horizontal elements, contributing to significant time savings and ensuring compliance with stringent building codes. These varied applications demonstrate our commitment to delivering reliable solutions that meet the diverse needs of the construction industry, consistently achieving superior structural outcomes and client satisfaction.

Quality Assurance, Certifications, and Industry Authority

Our dedication to delivering exceptional concrete cover for rebar solutions is underpinned by a robust quality assurance framework and adherence to international standards. We operate under ISO 9001 certified quality management systems, ensuring consistency and excellence across all manufacturing and supply chain processes. Our products, including all `reinforcing bar positioners` and `cover reinforcement` accessories, undergo rigorous testing, often exceeding the requirements of industry benchmarks such as ASTM (American Society for Testing and Materials) and EN (European Standards).

These tests include compressive strength, material durability, impact resistance, and precise dimensional accuracy, confirming that our spacers provide the exact concrete cover for rebar specified by engineering designs. Our long-standing relationships with leading contractors and engineering firms, some spanning over a decade, attest to our consistent product quality and reliable service. We actively participate in industry associations and contribute to the development of best practices in concrete construction, further solidifying our position as an authoritative voice in the field of formwork accessories.

Our internal laboratory capabilities allow for continuous product improvement and validation, providing clients with data-driven confidence in our offerings. This commitment to quality and scientific rigor ensures that our products are not merely compliant but are designed for superior performance and longevity in the most demanding construction environments.

Frequently Asked Questions (FAQ)

-

Q: What is the primary purpose of concrete cover for rebar?

A: The primary purpose is to protect the reinforcing steel (rebar) from corrosion, provide adequate fire resistance, and ensure proper bond between the concrete and steel, which is critical for the structural integrity and durability of concrete elements.

-

Q: How do you ensure the correct concrete cover depth?

A: We ensure correct cover depth through the use of precisely manufactured reinforcing bar positioners (spacers) that are designed to specific heights. These spacers are placed at regular intervals on the reinforcement cage to maintain the exact distance between the rebar and the formwork.

-

Q: What materials are your concrete cover spacers made from?

A: Our spacers are primarily manufactured from high-quality recycled or virgin plastics (PVC, HDPE) for general applications, and high-strength fiber cement or concrete for demanding environments where fire resistance, chemical inertness, and superior bonding are required.

-

Q: What is your typical delivery lead time for orders?

A: Our standard delivery lead time typically ranges from 7 to 14 business days, depending on the order volume, product type, and destination. For large-scale or custom orders, we provide a detailed production and delivery schedule during the quotation process to ensure timely project execution.

-

Q: Do you offer a warranty on your cover reinforcement products?

A: Yes, we stand by the quality of our products. Our concrete cover accessories come with a standard warranty against manufacturing defects, ensuring they meet specified performance criteria. For detailed warranty terms and conditions, please contact our sales team.

-

Q: How do your products contribute to sustainable construction?

A: By ensuring optimal concrete cover for rebar, our products extend the lifespan of concrete structures, reducing the need for premature repairs or replacement, which conserves resources and reduces waste. Additionally, we utilize recycled materials where feasible in our plastic spacers, contributing to circular economy principles.

Contact and Support

At Formwork Reinforced, we are committed to providing exceptional service and technical support for all your concrete cover for rebar needs. Our team of experts is available to assist with product selection, technical specifications, custom solutions, and logistical planning. We pride ourselves on responsive customer service and building long-term partnerships based on trust and reliability.

Whether you are planning a new project or require immediate assistance, our dedicated support channels are ready to help ensure your construction projects achieve optimal `cover reinforcement` and structural durability.

References

- ACI Committee 318. (2019). Building Code Requirements for Structural Concrete (ACI 318-19) and Commentary. American Concrete Institute.

- European Committee for Standardization. (2004). Eurocode 2: Design of concrete structures – Part 1-1: General rules and rules for buildings (EN 1992-1-1).

- Mehta, P. K., & Monteiro, P. J. M. (2014). Concrete: Microstructure, Properties, and Materials (4th ed.). McGraw-Hill Education.

- Broomfield, J. P. (2007). Corrosion of Steel in Concrete: Understanding, Investigation and Repair. Spon Press.

- International Organization for Standardization. (2015). Quality management systems – Requirements (ISO 9001:2015).

-

The Impact of Weather Conditions on Scaffold Platform PerformanceNewsAug.01,2025

-

The Fundamental Role of Steel Keel in Building StructuresNewsAug.01,2025

-

The Advantages of Aluminium Scaffolding for Sale in the Construction MarketNewsAug.01,2025

-

Supply Chain Optimization in Joist Reinforcement Plate ProductionNewsAug.01,2025

-

Material Grades and Their Significance in Column Rebar SelectionNewsAug.01,2025

-

How to Select the Right Timber Steel for Structural ApplicationsNewsAug.01,2025

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025