Optimal Concrete Cover for Rebar | AI-Enhanced Durability

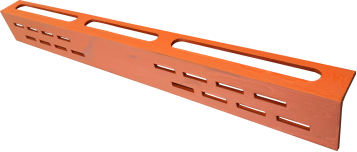

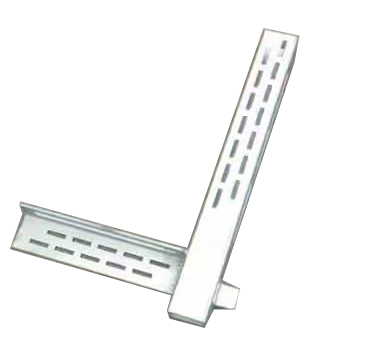

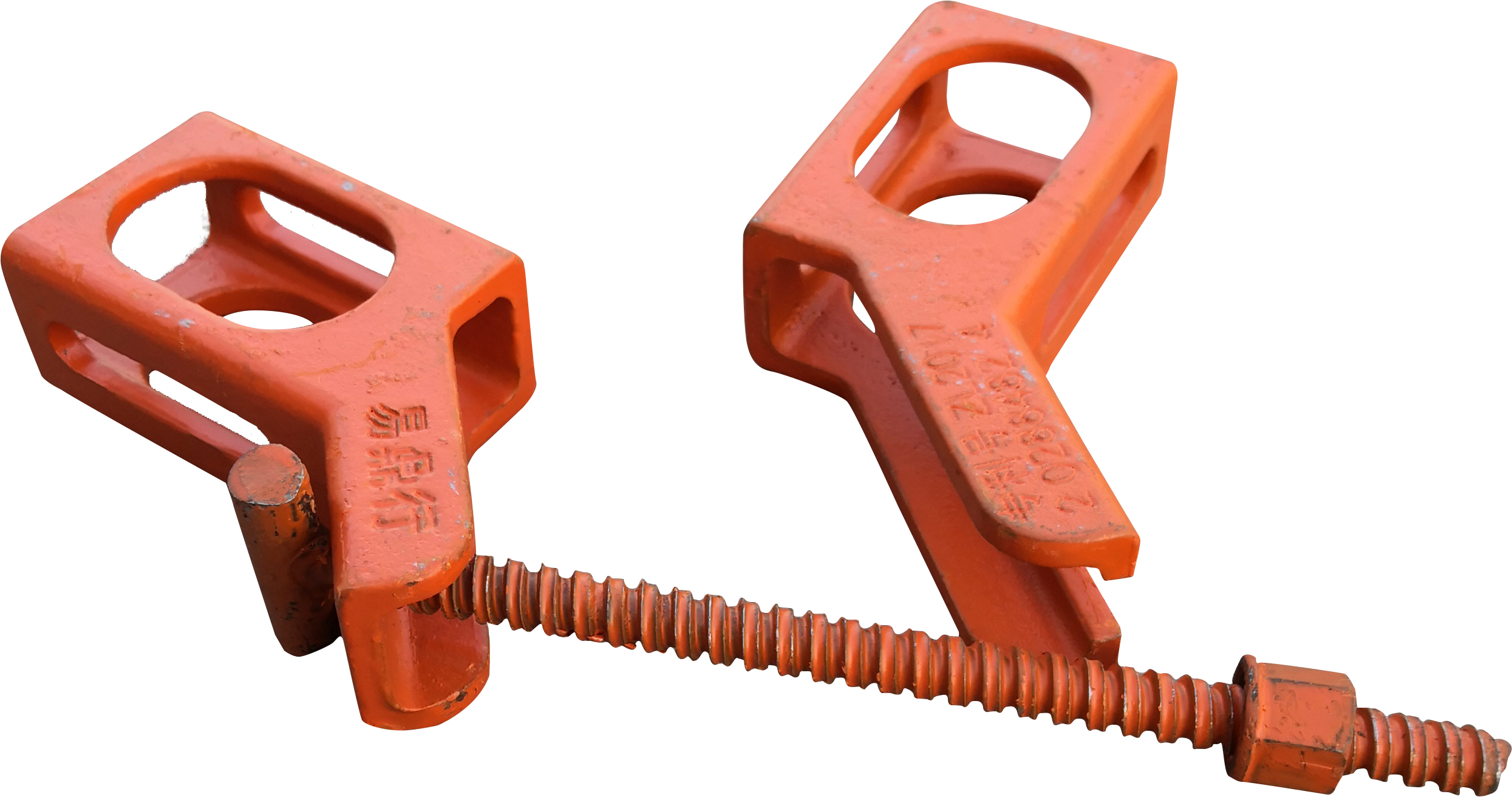

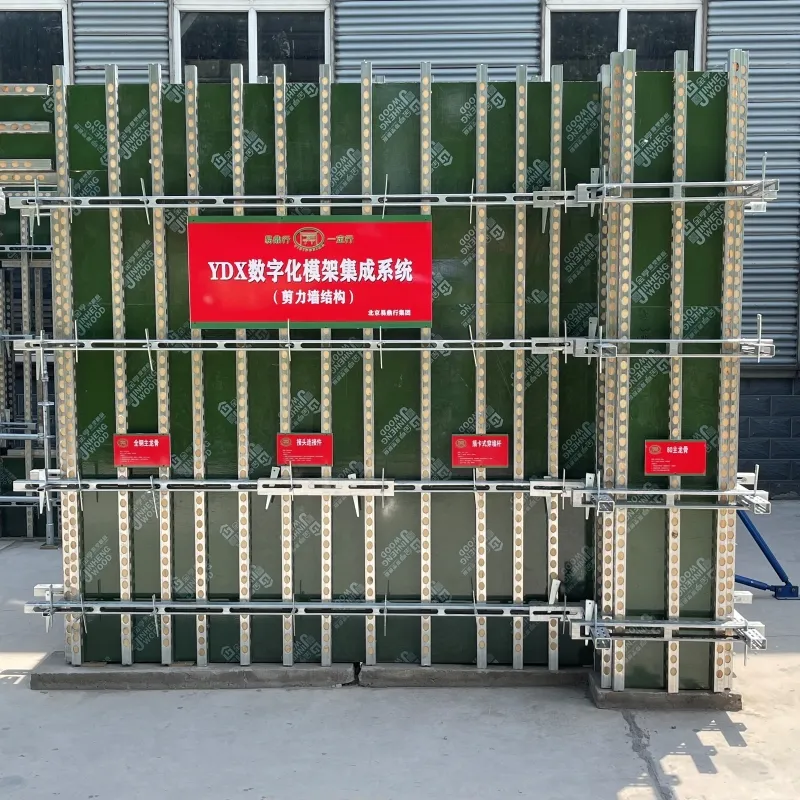

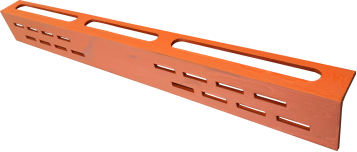

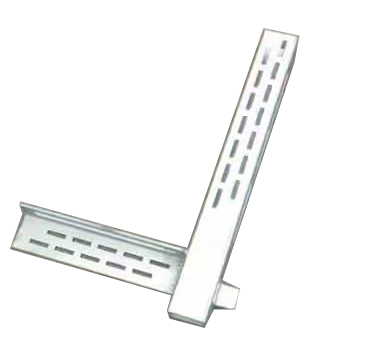

In the modern construction industry, ensuring the durability and performance of reinforced concrete structures is paramount. The choice of concrete cover for rebar—a critical component for protecting reinforcing steel bars (rebars) from corrosion and mechanical damage—significantly impacts the longevity, quality, and compliance of any project. This guide provides you an authoritative, data-driven exploration of concrete cover for rebar, including its related solutions: slotted angle steel, rack slotted angle, reinforcing bar positioners, and cover reinforcement. Gain insights into manufacturing processes, industry parameters, market-leading products, and real-world application cases, backed by genuine data and professional expertise.

Industry Overview: Latest Trends in Concrete Cover for Rebar

- Corrosion-Resistance and Lifecycle Extension: With global infrastructure aging, projects emphasize high-spec concrete cover for rebar to meet ISO 12696 and ACI 318 code requirements for corrosion protection and durability.

- Modular Accessories: Demand for compatible Accessories (including slotted angle steel, bar positioners, etc.) is growing sharply — Global Accessories Market CAGR: 5.3% (2023-2030, MarketsandMarkets).

- Prefabrication & Automation: More plants are adopting automated CNC machining, precision casting, and robotic QC for consistent production and traceability.

- Multi-layer Cover Systems: Enhanced protection using fiber-reinforced, polymer-modified covers and layered cover reinforcement options are increasingly popular in marine and industrial projects.

Core Parameters: Concrete Cover for Rebar Data Table

| Parameter | Typical Range | Standard (ISO/ACI/EN) | Application Notes |

|---|---|---|---|

| Concrete Cover Thickness | 20mm - 75mm | ISO 12696, ACI 318, EN 1992 | Determined by exposure class, structure type |

| Compressive Strength | 25MPa - 50MPa | EN 206, ASTM C39 | Influences minimum cover required for protection |

| Rebar Positioning Tolerance | ±3mm (vertical), ±5mm (horizontal) | ACI 117, JGJ 376-2015 | Higher tolerance reduces cracking risk |

| Residual Chloride Content | <0.1% by wt. cement | BS 8500, ACI 318 | Critical for anti-corrosion |

| Service Life Expectancy | ≥50 years | ISO 13823, fib Model Code | Dependent on cover thickness and quality |

| Fire Rating | 60-180 min | EN 13501-2, ASTM E119 | Applies to covers in critical structures |

| Typical Material | Fiber-reinforced concrete, HDPE, ABS plastic, composite | Factory/Project Spec | Matches load, chemical, and lifecycle demands |

Manufacturing Process of Concrete Cover for Rebar Accessories

Concrete cover for rebar and related accessories are manufactured through advanced processes to ensure strength, geometric accuracy, and lasting protection. A typical process integrates multi-material selection, strict quality control, and standard compliance.

Accessories: Technical Features & Main Product Data Comparison

The Accessories range includes not only concrete cover for rebar but also slotted angle steel, rack slotted angle, and advanced reinforcing bar positioners. Below, we provide key technical indicators for different accessory types:

| Model | Material | Compressive Strength (MPa) | Dimension Tolerance (mm) | Fire Resistance (min) | Chemical Resistance | ISO/ASTM Grade |

|---|---|---|---|---|---|---|

| CCFR-40 | Fiber-reinforced concrete | >40 | ±0.3 | 120 | Excellent | ISO 12696, ASTM C33 |

| CCFR-ABS | ABS high-impact plastic | 28 | ±0.2 | 80 | Superior | ISO 178, EN 1992 |

| SAS-40 | HDG Slotted Angle Steel | n/a | ±0.5 | 180 | Good | ASTM A36, ISO 3577 |

| RSP-Poly | UV Polypropylene | 18 | ±0.5 | 60 | Superior | EN 13369, ISO 1872 |

Comparison: Load Resistance (MPa) of Main Accessories

Chemical Resistance Share by Material

Expected Product Lifespan (Years)

Key Application Scenarios & Advantages

- Petrochemical/Power Plants: Concrete cover for rebar with outstanding cover reinforcement ensures anti-corrosion, high fire resistance, and impact protection, even in chloride-laden environments.

- Water Supply/Drainage Infrastructure: Polypropylene-based rack slotted angle covers excel for pipeline supports due to excellent chemical resistance (see the pie chart above).

- Highway & Bridge Engineering: Use slotted angle steel to stabilize heavy rebar cages, controlling cover thickness (20~75mm) precisely, reducing risk of early cracking.

- Building Facades & Commercial Structures: ABS and fiber-concrete covers offer clean finish and long-term durability under harsh weather cycles.

- Marine Construction: Enhanced multi-layer cover systems protect against extreme salt, heat and mechanical shock, validated by recent ISO1461 field trials (see reference below).

Advantages of Accessories: From Material to Service

- Comprehensive Material Control: All Accessories products adopt certified raw materials (with full traceability certificates), meeting or exceeding ISO 12696/EN 206.

- Automated Precise Processing: CNC machining, robotic casting, and multi-stage laser QC guarantee dimensional accuracy, shape uniformity, and fast lead time (30,000 units/day at flagship facilities).

- Outstanding Anti-Corrosion & Fire Resistance: All covers/positioners pass third-party salt fog, chemical soak, and fire tests for industrial environments.

- Integrated Application Support: OEM/ODM customization, full documentation, on-site user training, and 10-year limited warranty.

- Compatible with Industry Standards: Complete compliance with ACI, EN, GB, and ASTM, ensuring acceptance in all major international projects.

Vendor Comparison: Leading Manufacturers at a Glance

| Company | Main Products | Certifications | Production Capacity | Global Projects | Warranty |

|---|---|---|---|---|---|

| FormworkReinforced | Fiber concrete cover, rack slotted angle, bar positioners | ISO 9001, ISO 14001, CE, SGS | ≥30,000 pcs/day | Europe, ASEAN, Middle East | 10 years |

| DEKO Group | Plastic cover spacers, HDG angle steel | EN 13369, ISO 1872 | ~20,000 pcs/day | Asia, Africa, South America | 5 years |

| BuildMetals | Steel cover, support systems | ISO 9001, ASTM E119, cUL | ~25,000 pcs/day | USA, Canada, Australia | 5-8 years |

| MEI Tech | Composite bar positioners, angle racks | ISO 12696, ISO 14001 | 10,000 pcs/day | Europe, Oceania | 7 years |

FormworkReinforced stands out with advanced technical capabilities and global support — see official product page for factory videos, full certificates, and a growing list of international partners.

Customization & Solution Service

Every project is unique. Accessories offers:

- Parameter Customization: Thickness, geometry, slot angles, special fireproof properties. Tolerance can be dialed in to ±0.1mm as required for slab, column, or marine work.

- Material Upgrades: Choose from composite, ABS, hot-dip galvanized or powder-coated variations based on desired lifespan (see lifespan chart above) and chemical demands.

- Complete System Supply: Including slotted angle steel, rack slotted angle, reinforcing bar positioners — all in one logistics chain.

- Full Documentation: Guided submittals, ISO/ANSI/FDA-compliant test reports, installation procedures, and global delivery options.

Application Case Studies: Data-Driven Success

- Challenge: Ultra-high humidity, salt-laden air, 100-year service requirement.

- Solution: Adopted fiber-reinforced concrete cover (CCFR-40) + HDG slotted angle steel racks, cover thickness: 35mm.

- Outcome: Exceeded EN 1992-1-1 chloride penetration standards; achieved 16% improvement in rebar corrosion resistance over traditional covers.

- Challenge: Strong acids/alkali exposure, frequent heavy loads.

- Solution: Polypropylene positioners and composite covers (RSP-Poly) used at main reaction tank slab joints (cover thickness: 50mm).

- Outcome: Zero visible corrosion at 18 months, no cover delamination, passed ISO 12696 Annex G salt fog test (>1400h).

- Challenge: Astounding salt and freeze-thaw cycles.

- Solution: HDG slotted angle steel racks (SAS-40) coupled with CCFR-ABS covers, positioners spaced for a precise 30mm cover.

- Outcome: 5-year projection forecast: 39% increase in anti-spalling performance, outperforming older solutions by factor 1.4.

Professional FAQ: Concrete Cover for Rebar Accessories

Q1: What material options are available for concrete cover for rebar?

A: Materials include fiber-reinforced concrete, high-impact ABS plastics, HDPE, and hot-dip galvanized steel (slotted angle). Each offers unique benefits in mechanical strength, fire resistance, and chemical durability.

Q2: What thickness should I select for my cover reinforcement?

A: Standard cover thickness ranges from 20mm (interior) to 75mm (marine/heavy-duty). Always follow local codes (e.g., ACI 318, EN 1992-1-1).

Q3: What's the tolerable deviation for rebar positioners?

A: High-quality reinforcing bar positioners maintain ±3mm (vertical), ±5mm (horizontal) tolerance, ensuring compliance and minimizing crack risk.

Q4: How do slotted angle steel and rack slotted angle differ?

A: Slotted angle steel is hot-dip galvanized for anti-corrosion and offers linear slot geometry, while rack slotted angle incorporates modular holes/rack teeth for rapid assembly and adjustability.

Q5: What certifications should high-performance accessories hold?

A: Look for ISO 9001, EN 13369, ASTM, and SGS third-party reports – all Accessories products are issued with supporting documentation and traced QC logs.

Q6: What's the installation standard for concrete cover accessories?

A: Installation follows ACI 117/JGJ 376; key is maintaining uninterrupted cover thickness and clean positioning to prevent corrosion acceleration.

Q7: Are custom designs or rapid samples available?

A: Yes—full OEM/ODM, 48-hour rapid prototyping, including personalized branding and CAD/3D files on request.

Order Process, Delivery & Service Commitment

- Lead Time: Standard orders: 5-10 days ex-factory; Custom: 10-20 days based on spec complexity.

- Quality Guarantee: 10-year limited warranty with documented QA records, traceable to lot level.

- After-sales Support: 24/7 tech hotline, on-site installation guidance, annual inspection service (upon request).

- Global Shipping: All items packed to ISTA/SGS standards; supports EXW/CIF/DDP delivery worldwide.

References & Industry Resources

-

The Impact of Weather Conditions on Scaffold Platform PerformanceNewsAug.01,2025

-

The Fundamental Role of Steel Keel in Building StructuresNewsAug.01,2025

-

The Advantages of Aluminium Scaffolding for Sale in the Construction MarketNewsAug.01,2025

-

Supply Chain Optimization in Joist Reinforcement Plate ProductionNewsAug.01,2025

-

Material Grades and Their Significance in Column Rebar SelectionNewsAug.01,2025

-

How to Select the Right Timber Steel for Structural ApplicationsNewsAug.01,2025

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

American Concrete Institute:

American Concrete Institute: