ינו . 30, 2025 01:42

Back to list

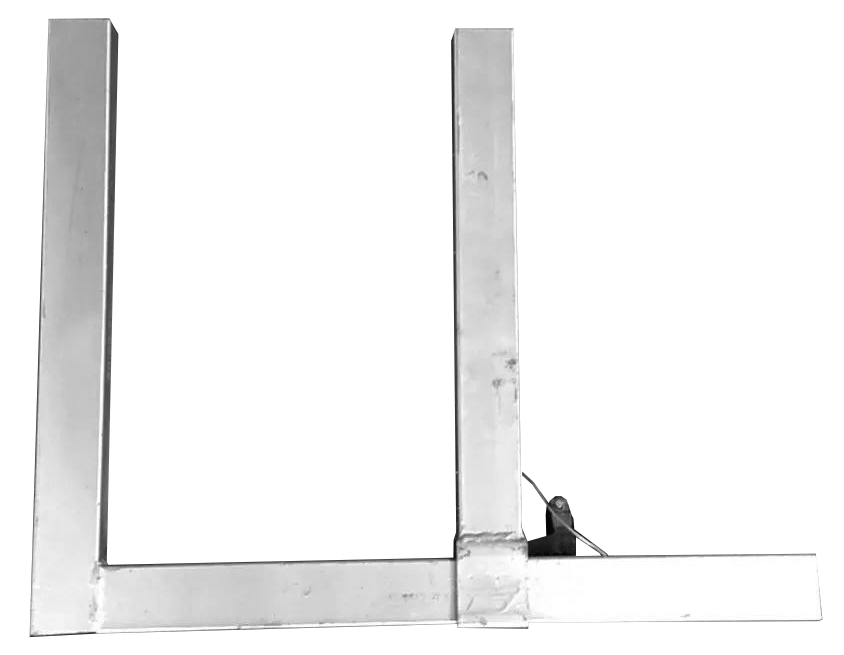

insulated formwork

Insulated formwork, often considered a game-changer in the construction industry, marries the adaptability of modern construction techniques with the thermal efficiencies of contemporary materials. From my extensive experience in the field, integrating insulated formwork into projects provides undeniable benefits in both energy performance and structural integrity. This cutting-edge technology is not just about building walls; it's about reshaping the future of sustainable construction.

Authoritativeness in the construction sector frequently aligns with a commitment to environmental responsibility. Insulated formwork systems demonstrate this commitment by significantly reducing a building's carbon footprint. The materials used are often recyclable, and the reduced energy consumption during the building’s lifespan further mitigates environmental impact. Trust is established with clients and stakeholders when they see a concerted effort to adhere to green building standards without sacrificing quality or safety. One must not overlook the operational efficiencies gained during the construction phase. From a project manager's perspective, the speed of assembly with insulated formwork is notably quicker compared to traditional methods. With panels ready to be slotted together like pieces of a puzzle, construction teams can complete projects faster, reducing labor costs and minimizing project timelines. This expediency does not sacrifice precision, as the formwork ensures uniformity and high-quality finishes. The safety profile of insulated formwork is equally commendable. Concrete pouring between insulating panels provides a stable structure less prone to fire hazards, given concrete's inherent fire resistance. This factor alone makes insulated formwork an attractive option in building markets where safety regulations are stringent and paramount. Conclusively, choosing insulated formwork is a commitment to future-proofing construction practices. It merges traditional building knowledge with modern innovations, ensuring that structures stand the test of time while contributing positively to environmental conservation. As someone deeply involved in the progression of construction technologies, it is this synthesis of performance, innovation, and sustainability that positions insulated formwork as an indispensable component of modern architectural design and execution. By integrating insulated formwork, professionals can assure clients of a project’s longevity, efficiency, and compliance with the highest environmental standards.

Authoritativeness in the construction sector frequently aligns with a commitment to environmental responsibility. Insulated formwork systems demonstrate this commitment by significantly reducing a building's carbon footprint. The materials used are often recyclable, and the reduced energy consumption during the building’s lifespan further mitigates environmental impact. Trust is established with clients and stakeholders when they see a concerted effort to adhere to green building standards without sacrificing quality or safety. One must not overlook the operational efficiencies gained during the construction phase. From a project manager's perspective, the speed of assembly with insulated formwork is notably quicker compared to traditional methods. With panels ready to be slotted together like pieces of a puzzle, construction teams can complete projects faster, reducing labor costs and minimizing project timelines. This expediency does not sacrifice precision, as the formwork ensures uniformity and high-quality finishes. The safety profile of insulated formwork is equally commendable. Concrete pouring between insulating panels provides a stable structure less prone to fire hazards, given concrete's inherent fire resistance. This factor alone makes insulated formwork an attractive option in building markets where safety regulations are stringent and paramount. Conclusively, choosing insulated formwork is a commitment to future-proofing construction practices. It merges traditional building knowledge with modern innovations, ensuring that structures stand the test of time while contributing positively to environmental conservation. As someone deeply involved in the progression of construction technologies, it is this synthesis of performance, innovation, and sustainability that positions insulated formwork as an indispensable component of modern architectural design and execution. By integrating insulated formwork, professionals can assure clients of a project’s longevity, efficiency, and compliance with the highest environmental standards.

Share

Latest news

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

Related Products