פבר . 16, 2025 02:24

Back to list

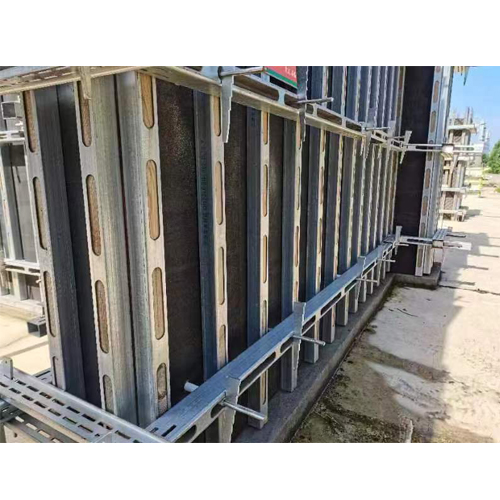

Scaffolding

Navigating through the construction landscape reveals a pivotal component that often goes unnoticed, yet plays an instrumental role in ensuring safety and efficiency—aluminium scaffold fittings. These fittings, the unsung heroes of scaffolding systems, elevate the performance of the frameworks supporting workers and materials at towering heights.

Trustworthiness is another pillar upon which the reputation of aluminium scaffold fittings is built. Their track record in diverse climates and conditions has earned them a position of reliability among construction professionals worldwide. Clients and project managers prefer these fittings due to the predictable quality they offer, which consistently aligns with the high safety standards expected within the industry. Trust further fosters collaborative relationships between providers of these fittings and the construction companies, leading to better results and enhanced project satisfaction. The environmental impact of construction activities is another aspect where aluminium scaffold fittings show their merit. Unlike other materials that might contribute significantly to environmental degradation, aluminium is applauded for its sustainability. It is 100% recyclable, meaning that at the end of its lifecycle, it can be reprocessed without loss of properties. This feature supports the growing trend toward sustainable construction practices, enabling companies to reduce their carbon footprint and contribute positively to environmental conservation efforts. Choosing the right aluminium scaffold fittings involves considering several crucial factors a builder cannot afford to overlook. Quality should take precedence to ensure durability and safety, and builders are encouraged to source fittings from reputable manufacturers with proven track records. Moreover, understanding the specific needs of a construction project—whether it's scale, design complexity, or environmental conditions—will guide in selecting the fittings that enhance both performance and cost-effectiveness. In conclusion, aluminium scaffold fittings play an indispensable role in the intricate web of the construction process. They ensure worker safety through their lightweight and corrosion-resistant properties, while also boasting versatility, making them adaptable to various scaffolding designs. Their compliance with international safety standards reinforces their authority, while their long-standing reliability underpins the trust they have garnered. Moreover, their contribution to sustainable building practices positions them as a forward-thinking choice in today's environmentally conscious market. As the industry progressively shifts toward more innovative and sustainable solutions, aluminium scaffold fittings will undoubtedly remain at the forefront, steering construction activities toward safer, more efficient, and eco-friendly horizons.

Trustworthiness is another pillar upon which the reputation of aluminium scaffold fittings is built. Their track record in diverse climates and conditions has earned them a position of reliability among construction professionals worldwide. Clients and project managers prefer these fittings due to the predictable quality they offer, which consistently aligns with the high safety standards expected within the industry. Trust further fosters collaborative relationships between providers of these fittings and the construction companies, leading to better results and enhanced project satisfaction. The environmental impact of construction activities is another aspect where aluminium scaffold fittings show their merit. Unlike other materials that might contribute significantly to environmental degradation, aluminium is applauded for its sustainability. It is 100% recyclable, meaning that at the end of its lifecycle, it can be reprocessed without loss of properties. This feature supports the growing trend toward sustainable construction practices, enabling companies to reduce their carbon footprint and contribute positively to environmental conservation efforts. Choosing the right aluminium scaffold fittings involves considering several crucial factors a builder cannot afford to overlook. Quality should take precedence to ensure durability and safety, and builders are encouraged to source fittings from reputable manufacturers with proven track records. Moreover, understanding the specific needs of a construction project—whether it's scale, design complexity, or environmental conditions—will guide in selecting the fittings that enhance both performance and cost-effectiveness. In conclusion, aluminium scaffold fittings play an indispensable role in the intricate web of the construction process. They ensure worker safety through their lightweight and corrosion-resistant properties, while also boasting versatility, making them adaptable to various scaffolding designs. Their compliance with international safety standards reinforces their authority, while their long-standing reliability underpins the trust they have garnered. Moreover, their contribution to sustainable building practices positions them as a forward-thinking choice in today's environmentally conscious market. As the industry progressively shifts toward more innovative and sustainable solutions, aluminium scaffold fittings will undoubtedly remain at the forefront, steering construction activities toward safer, more efficient, and eco-friendly horizons.

Share

Next:

Latest news

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

Related Products