Jan . 15, 2025 04:06

Back to list

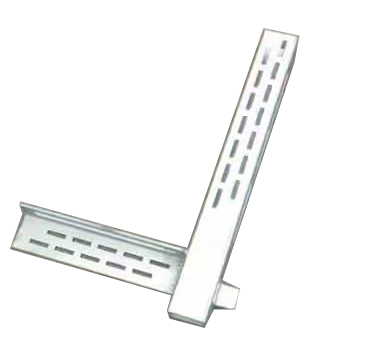

Scaffolding accessories

The construction industry is an ever-evolving field that demands efficiency, safety, and precision. One critical component is the use of standard slab formwork, a foundational aspect of concrete construction that provides support and shape to poured concrete slabs. As a seasoned expert in construction engineering, I have navigated numerous projects where mastery of slab formwork has been pivotal to success.

Technical precision in the use of formworks goes hand in hand with the authoritative regulations set forth by industry standards. Compliance with norms such as those established by the American National Standards Institute (ANSI) or the Occupational Safety and Health Administration (OSHA) enhances safety and trustworthiness in construction practice. Adherence to these guidelines is non-negotiable; it is essential in demonstrating professionalism and commitment to safety. Trust is reinforced through transparency and consistent communication. Engaging with all stakeholders, from architects to site engineers and laborers, ensures shared understanding and expectations. Regular site inspections and quality checks further cement the reliability and authority of slab formwork practices. Emerging technologies, such as Building Information Modeling (BIM), are transforming this facet of construction by allowing accurate and detailed planning of formwork systems. Adopting such technologies reinforces a company's reputation as a leader in innovation, projecting authority and forward-thinking. In conclusion, standard slab formwork is more than just a necessity in construction; it is a testament to engineering prowess, safety, and innovation. Through expert planning, strict adherence to standards, and the leveraging of modern technologies, construction professionals can maximize the effectiveness of these systems. With trust and expertise at the forefront, the use of standard slab formwork can be a cornerstone of superior construction projects that stand the test of time.

Technical precision in the use of formworks goes hand in hand with the authoritative regulations set forth by industry standards. Compliance with norms such as those established by the American National Standards Institute (ANSI) or the Occupational Safety and Health Administration (OSHA) enhances safety and trustworthiness in construction practice. Adherence to these guidelines is non-negotiable; it is essential in demonstrating professionalism and commitment to safety. Trust is reinforced through transparency and consistent communication. Engaging with all stakeholders, from architects to site engineers and laborers, ensures shared understanding and expectations. Regular site inspections and quality checks further cement the reliability and authority of slab formwork practices. Emerging technologies, such as Building Information Modeling (BIM), are transforming this facet of construction by allowing accurate and detailed planning of formwork systems. Adopting such technologies reinforces a company's reputation as a leader in innovation, projecting authority and forward-thinking. In conclusion, standard slab formwork is more than just a necessity in construction; it is a testament to engineering prowess, safety, and innovation. Through expert planning, strict adherence to standards, and the leveraging of modern technologies, construction professionals can maximize the effectiveness of these systems. With trust and expertise at the forefront, the use of standard slab formwork can be a cornerstone of superior construction projects that stand the test of time.

Share

Next:

Latest news

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

Related Products