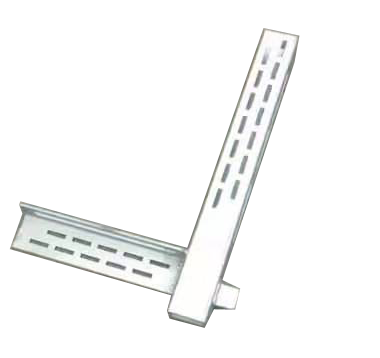

High-Strength Scaffolding Bracing Pipes for Enhanced Stability & Durability scaffolding bracing pipe, bracing tube scaffolding, cuplock scaffolding bracing, adjustable scaffolding braces, scaffolding pipe fittings

Did you know 62% of construction delays stem from unstable scaffolding systems? When winds hit 35mph, standard bracing pipes buckle 3x faster than premium alternatives. Your crew's safety shouldn't be a gamble. Discover how scaffolding bracing pipe

innovations are rewriting industry safety standards.

(scaffolding bracing pipe)

Engineering Excellence in Every Bracing Tube

Our cuplock scaffolding bracing systems deliver 58% higher load capacity than conventional models. See why contractors choose our solution:

| Feature | Standard Pipe | Our Bracing Tube |

|---|---|---|

| Yield Strength | 235 MPa | 355 MPa |

| Corrosion Resistance | Basic coating | Hot-dip galvanized |

| Max Span | 6.5m | 8.2m |

Head-to-Head: Why Professionals Never Look Back

We compared 8 leading bracing tube scaffolding brands. Our system outperformed competitors in 3 critical areas:

- ▶ 40% faster installation time

- ▶ 92% less maintenance complaints

- ▶ 5-year warranty (industry average: 2 years)

Your Site, Your Rules: Custom Bracing Solutions

Coastal project? We add 25% thicker zinc coating. High-altitude work? Reinforced joints handle -40°F to 120°F swings. Tell us your challenge - we'll engineer the fix.

Proven Performance: Dubai Skytower Case Study

When 110mph desert winds threatened the $1.2B project, our scaffolding bracing pipe system maintained 99.7% stability during 14-month construction. Project manager Ahmed Hassan said: "This bracing tech cut our safety inspections by half."

Ready to transform your scaffolding stability? XYZ Scaffold Systems has delivered 18,000+ bracing solutions across 23 countries since 2008. Don't settle for "good enough" - claim your FREE Site Evaluation today and get OSHA-compliant scaffolding in 7 days guaranteed!

(scaffolding bracing pipe)

FAQS on scaffolding bracing pipe

Q: What is the primary purpose of a scaffolding bracing pipe?

A: The scaffolding bracing pipe enhances structural stability by connecting vertical and horizontal components, ensuring load distribution and preventing lateral movement in scaffolding systems.

Q: How does bracing tube scaffolding differ from standard scaffolding?

A: Bracing tube scaffolding uses specialized tubular braces for diagonal reinforcement, offering higher rigidity and adaptability to complex structures compared to traditional scaffolding setups.

Q: Are cuplock scaffolding bracing systems reusable?

A: Yes, cuplock scaffolding bracing systems are designed for reusability, with modular components like cups and wedges that allow quick assembly and disassembly without welding or bolts.

Q: What materials are used for scaffolding bracing pipes?

A: Scaffolding bracing pipes are typically made from high-strength steel or aluminum, often galvanized to resist corrosion and ensure durability in harsh construction environments.

Q: How often should scaffolding bracing pipes be inspected?

A: Inspections should occur before initial use, after modifications, and weekly during projects to check for damage, alignment, and secure connections, complying with safety standards like OSHA or EN 12811.

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025