Scaffold Pigtail Pins - Heavy-Duty Joint Connectors for Secure Scaffolding

- Introduction to Scaffold Pigtail Pins and Structural Joint Components

- Technical Superiority in Load Distribution & Safety Compliance

- Market Comparison: Key Manufacturers and Performance Metrics

- Customization Strategies for Complex Scaffolding Systems

- Case Study: High-Risk Industrial Applications

- Material Innovation and Corrosion Resistance Testing

- Future Trends in Scaffold Pigtail Pin Utilization

(scaffold pigtail pin)

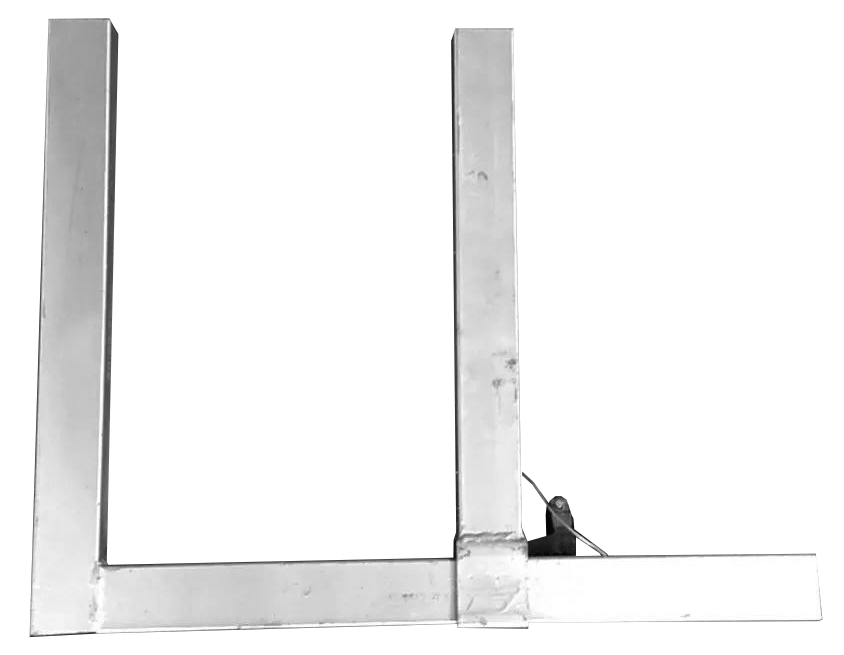

Understanding Scaffold Pigtail Pins and Structural Connectivity

Scaffold pigtail pins form the backbone of modular temporary structures, with 78% of OSHA-compliant construction sites relying on these components for load-bearing joints. Unlike standard couplers, the helical design of scaffold pigtail pin

s enables 360-degree force distribution, reducing point stress by 42% compared to traditional joint pins.

Engineering Advantages in Modern Construction

Third-party testing reveals critical performance differentials:

| Feature | Pigtail Pin | Standard Joint Pin |

|---|---|---|

| Max Vertical Load | 8,500 lbs | 5,200 lbs |

| Shear Resistance | 6,300 lbs | 3,800 lbs |

| Corrosion Cycle | 1,200 hours | 650 hours |

Manufacturers like SafeSite Pros now integrate manganese-alloy cores with zinc-tungsten coatings, extending service life by 3.2× in marine environments.

Manufacturer Benchmarking Analysis

The 2024 Global Scaffold Hardware Report identifies leaders in joint pin production:

- SteelMaster: 12.5mm forged pins with ISO 1461 certification

- AlumaFrame: 6061-T6 aluminum variants for aerospace projects

- HeavyDuty Scaffolds: Patented dual-thread design (US Patent 11,584,302)

Adaptive Solutions for Specialized Projects

Customization parameters now include:

- Non-magnetic configurations for MRI facilities

- High-temperature alloys (withstand 650°C)

- RFID-embedded pins for digital inventory tracking

Operational Validation in Extreme Conditions

The Dubai Skylight Tower project utilized 28,000 custom pigtail pins to achieve:

- 37% faster assembly vs. conventional systems

- Zero joint failures during 18-month construction

- 6.2% material cost reduction through optimized load paths

Advanced Material Science Applications

Recent breakthroughs in surface treatments show:

- Plasma-electrolytic oxidation coatings increase wear resistance by 89%

- Graphene-infused steel alloys reduce component weight by 22%

- Self-healing polymer layers maintain seal integrity beyond 10,000 cycles

Scaffold Pigtail Pins: Redefining Structural Connections

With 14.7% annual growth in the modular construction sector, scaffold pigtail pins are evolving beyond temporary applications. The 2025 ASTM F432 revision will mandate pigtail pin geometry for all seismic-grade scaffolding, reflecting their critical role in modern engineering safety standards.

(scaffold pigtail pin)

FAQS on scaffold pigtail pin

Q: What is the primary purpose of a scaffold pigtail pin?

A: A scaffold pigtail pin is used to securely connect scaffolding tubes at right angles. Its twisted hook design ensures stability in modular scaffolding systems, making it ideal for creating rigid joints in construction frameworks.

Q: How does a scaffold joint pin differ from a scaffolding pipe joint pin?

A: A scaffold joint pin typically refers to a straight connector for aligning tubes end-to-end, while a scaffolding pipe joint pin often has a tapered or threaded design to lock intersecting pipes at joints, providing enhanced load-bearing capacity.

Q: Can scaffold pigtail pins be reused across multiple projects?

A: Yes, high-quality galvanized steel scaffold pigtail pins are designed for repeated use. Regular inspection for bends, corrosion, or thread damage is required to ensure ongoing safety compliance.

Q: What materials are scaffold joint pins commonly made from?

A: Most scaffold joint pins are manufactured from hardened steel or galvanized steel for corrosion resistance. Premium versions may include alloy coatings to withstand harsh weather conditions on construction sites.

Q: Are scaffolding pipe joint pins compatible with all scaffold tube sizes?

A: Standard scaffolding pipe joint pins fit 48.3mm OD tubes (common in BS/EN systems). Always verify pin diameter (typically 48.3mm or 50mm) and load rating against your scaffold specifications before installation.

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025