Fév . 13, 2025 02:42

Back to list

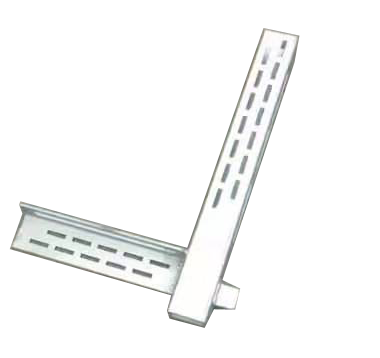

aluminium scaffolding for sale

Formwork scaffolding is an indispensable component in the construction industry, offering support and shaping for concrete structures during the building process. As buildings reach for the sky and architectural designs become more intricate, the demand for reliable and efficient formwork scaffolding systems rises, necessitating expertise and trustworthiness in their selection and usage.

Authoritativeness in the field of formwork scaffolding often comes from manufacturers with long-standing reputations for quality. Companies with decades of experience in construction technology provide superior products backed by extensive research and development. They also offer substantial warranties and guarantees, standing by the durability and effectiveness of their systems. Construction managers and engineers are at an advantage when they actively seek insights and training on the latest formwork advancements and safety practices. Participating in workshops, engaging with industry experts, and staying updated with the latest industry standards are essential steps toward becoming proficient in formwork scaffolding applications. Trustworthiness is further established through transparent customer service and robust after-sales support. Leading manufacturers and suppliers typically provide on-site training and demonstrations, ensuring that the construction teams are well-versed in handling and assembling the scaffolding systems correctly. They also offer dedicated support channels to address any concerns or issues that may arise during the project's duration. In conclusion, selecting the right formwork scaffolding goes beyond mere acquisition; it involves understanding the complexities of the construction project, the specific demands of the design, and ensuring adherence to safety protocols. By choosing systems from reputable manufacturers with proven expertise and a commitment to quality and safety, construction projects can achieve greater efficiency, reliability, and safety, enhancing overall project success.

Authoritativeness in the field of formwork scaffolding often comes from manufacturers with long-standing reputations for quality. Companies with decades of experience in construction technology provide superior products backed by extensive research and development. They also offer substantial warranties and guarantees, standing by the durability and effectiveness of their systems. Construction managers and engineers are at an advantage when they actively seek insights and training on the latest formwork advancements and safety practices. Participating in workshops, engaging with industry experts, and staying updated with the latest industry standards are essential steps toward becoming proficient in formwork scaffolding applications. Trustworthiness is further established through transparent customer service and robust after-sales support. Leading manufacturers and suppliers typically provide on-site training and demonstrations, ensuring that the construction teams are well-versed in handling and assembling the scaffolding systems correctly. They also offer dedicated support channels to address any concerns or issues that may arise during the project's duration. In conclusion, selecting the right formwork scaffolding goes beyond mere acquisition; it involves understanding the complexities of the construction project, the specific demands of the design, and ensuring adherence to safety protocols. By choosing systems from reputable manufacturers with proven expertise and a commitment to quality and safety, construction projects can achieve greater efficiency, reliability, and safety, enhancing overall project success.

Share

Next:

Latest news

-

The Impact of Weather Conditions on Scaffold Platform PerformanceNewsAug.01,2025

-

The Fundamental Role of Steel Keel in Building StructuresNewsAug.01,2025

-

The Advantages of Aluminium Scaffolding for Sale in the Construction MarketNewsAug.01,2025

-

Supply Chain Optimization in Joist Reinforcement Plate ProductionNewsAug.01,2025

-

Material Grades and Their Significance in Column Rebar SelectionNewsAug.01,2025

-

How to Select the Right Timber Steel for Structural ApplicationsNewsAug.01,2025

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

Related Products