formwork and scaffolding

The Importance of Formwork and Scaffolding in Construction

In the realm of construction, the efficiency and safety of building processes are paramount. Two critical components that facilitate these processes are formwork and scaffolding. Each serves a unique purpose but is interconnected in the overall framework of a project. Understanding their roles, types, and best practices is essential for professionals in the industry.

What is Formwork?

Formwork refers to the temporary structure used to support the shaping of concrete until it cures and gains strength. Once the concrete has hardened, the formwork can be removed. This aspect of construction is critical as it determines the shape, structure, and finish of the final product. Formwork can be made from various materials, including wood, steel, plastic, or even aluminum, depending on the specific needs of the project.

There are several types of formwork

1. Traditional Timber Formwork This is the most common type, made from timber or plywood. It is usually easy to assemble and disassemble, making it suitable for various construction projects.

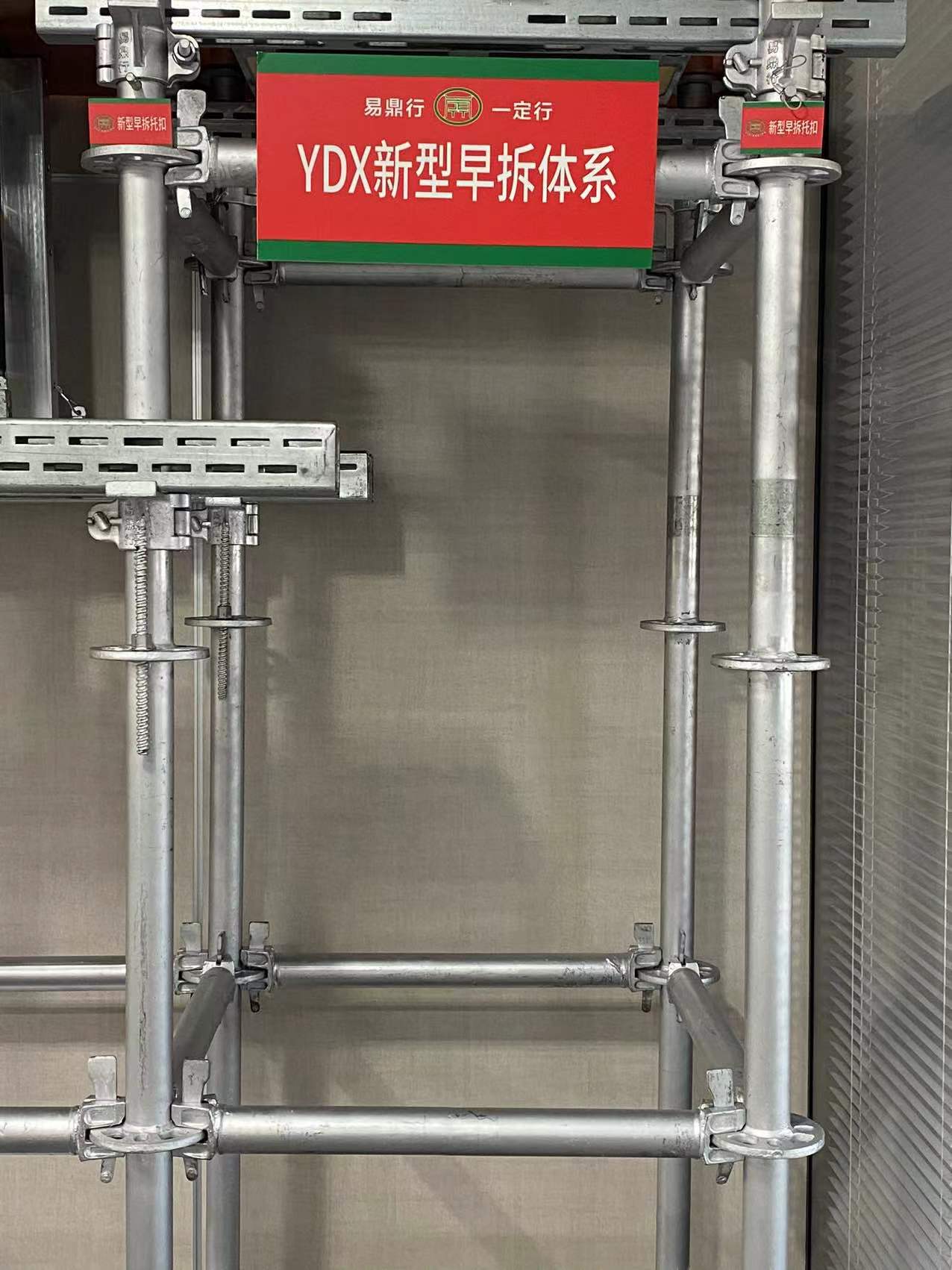

2. Engineered Formwork Systems These are prefabricated systems designed to be reused multiple times. They are typically made from steel or aluminum and are known for their durability and strength.

3. Single-Use Formwork As the name suggests, this type is used for a single pour and then discarded. It is commonly utilized in small-scale projects or where intricate shapes are needed.

4. Flexible Formwork This innovative approach allows for unique shapes and designs. Made from flexible materials, it is particularly useful for architectural projects requiring sculptural elements.

The Role of Scaffolding

Scaffolding complements formwork by providing a safe and stable platform for workers, materials, and equipment. It is essential for high-rise construction and projects that require work at height. Without proper scaffolding, construction tasks can become hazardous, significantly increasing the risk of accidents and injuries.

There are several types of scaffolding systems

formwork and scaffolding

1. Tube and Coupler Scaffolding This traditional method uses tubes and couplers to create a framework, offering flexibility in design and strength.

2. Prefabricated Modular Scaffolding These systems are manufactured off-site and are easier to assemble. They save time during the construction process and provide enhanced safety features.

3. Cantilever Scaffolding Used in situations where the scaffolding cannot be supported from the ground, such as extending over buildings, this type allows workers to work on higher elevations, enhancing operational efficiency.

4. Suspended Scaffolding Often used for tasks like window cleaning or façade repairs, this system is suspended from the structure itself and provides access to hard-to-reach areas.

Best Practices for Using Formwork and Scaffolding

Implementing best practices when using formwork and scaffolding is crucial for ensuring safety and efficiency. Here are some key considerations

- Planning and Design Proper planning should be undertaken to ensure that the formwork and scaffolding systems can support the necessary loads without compromising safety or structural integrity.

- Regular Inspections Routine checks on both formwork and scaffolding are essential. This includes assessing for wear and tear, potential structural weaknesses, and compliance with safety regulations.

- Training and Safety Protocols Workers must be trained on the correct use of formwork and scaffolding. Establishing clear safety protocols helps prevent accidents and ensures a secure working environment.

- Material Selection Choosing the right materials for both formwork and scaffolding can enhance safety and efficiency. For example, lightweight materials may ease transportation and assembly but should still meet strength requirements.

Conclusion

Formwork and scaffolding are indispensable tools in the construction industry. They not only promote efficient building practices but also ensure the safety of workers on site. As technology and materials continue to evolve, the capabilities of formwork and scaffolding systems will likely expand, leading to even more innovative construction solutions. By understanding and implementing best practices, construction professionals can harness the full potential of these critical components, contributing to successful project outcomes and a safer work environment.

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025