Bar Tie Reinforcement: Quality Assurance and Reinforcement Efficiency Enhancement

The viewpoint that 'Bar Tie Reinforcement has high quality and good reinforcement effect' is not groundless, but stems from a deep understanding and application of Bar Tie Reinforcement in practice. Bar Tie Reinforcing, As a traditional form of reinforced concrete structure, its quality and reinforcement effect directly affect the overall safety and service life of the building. This article will discuss why Bar Tie Reinforcement has the characteristics of high quality and good reinforcement effect from three aspects: material quality, construction technology, and reinforcement effect.

The quality of Bar Tie Reinforcement is highly dependent on the materials used

The selection of high-strength steel bars is the key to ensuring the structural bearing capacity. High quality steel bars have good tensile strength and ductility, which can effectively resist tensile stress when the beam is under stress, thereby avoiding or delaying concrete cracking. Meanwhile, high-quality cement is also an important factor in ensuring the strength of concrete. Reasonable mix proportions and sufficient curing can achieve the expected compressive strength of concrete and form a good bond with steel bars to jointly bear structural loads. Therefore, strict control of the quality of steel bars and concrete is the foundation for ensuring the quality of concrete cover for rebar.

Exquisite construction techniques are the guarantee for achieving high-quality Bar Tie Reinforcement

The binding of steel bars is not a simple process, but requires strict adherence to the requirements of the design drawings. The spacing, position, and overlap length of steel bars need to be precisely controlled to ensure that they can effectively play their load-bearing role. In addition, the pouring and vibration of concrete are also crucial. Uniform pouring and sufficient vibration can avoid voids and honeycombs inside the concrete, ensuring a tight bond between the steel bars and the concrete. Qualified workers need to possess proficient skills and rich experience to ensure the construction quality of cover for reinforcement.

Bar Tie Reinforcement has also shown excellent results in reinforcement

Due to its open structure, cover reinforcement has great flexibility in reinforcement and renovation. The load-bearing capacity and seismic performance of the beam can be effectively improved by increasing the quantity and specifications of steel bars, or by using external bonding of carbon fiber cloth. In addition, for some Bar Tie Reinforcements that have experienced a decrease in strength due to damage or corrosion, reinforcement can be achieved by locally replacing the steel bars or repairing the concrete. Compared to other types of beam structures, Bar Tie Reinforcement has higher operability and economy in reinforcement and renovation.

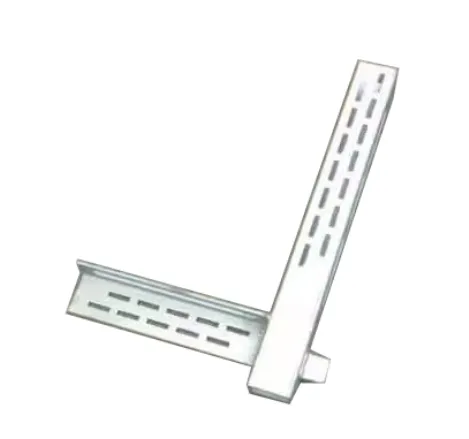

In summary, the reason why galvanized mending plate are considered to have "high quality and good reinforcement effect" is closely related to the quality of the materials used, exquisite construction techniques, and flexible reinforcement methods. In future engineering construction, we should continue to attach importance to the quality control of Bar Tie Reinforcement and constantly explore new technologies and methods for its reinforcement and renovation, so that it can play a greater role in the field of architecture. However, it should also be noted that with the continuous development of new building materials and construction technologies, we should actively explore and apply more efficient and environmentally friendly structural forms to meet the development needs of the times.

Bar Tie Reinforcing FAQs

What are the technical advantages of Bar Tie Reinforcement compared to traditional steel reinforcement binding?

High strength connection: using cold-rolled galvanized steel wire (tensile strength ≥ 550MPa), the anti slip force of the node is increased by 40%;

Accurate positioning: Pre formed U-shaped fasteners achieve a spacing error of ≤ ± 2mm between steel bars (manual binding ± 5mm);

Seismic performance: The triple winding process ensures that the nodes remain intact even under an 8-degree earthquake (traditional binding is prone to loosening).

How does Bar Tie Reinforcement ensure the reinforcement effect of key parts of concrete structures?

Core area strengthening: The beam column nodes are fixed with a composite of "X-shaped cross binding+metal hoops" (increasing shear bearing capacity by 35%);

Stress transmission optimization: The diagonal 45 ° binding tape guides the steel bars to cooperate in stress distribution, avoiding stress concentration;

Corrosion protection: Epoxy resin coated steel wire has a lifespan of up to 50 years in humid environments (ordinary iron wire only has 15 years).

How can the construction efficiency of Bar Tie Reinforcement be improved?

Mechanized operation: The single node operation time of the electric tying gun is only 3 seconds (15 seconds for manual operation), which increases efficiency by 5 times;

Prefabricated modularization: The wall panel steel mesh is pre tied in the factory (including QR code positioning labels) and lifted into place on site;

Intelligent acceptance: AI image recognition automatically detects the density of binding points (coverage rate ≥ 98% is qualified).

How can Bar Tie Reinforcement meet the requirements of ultra-high precision structural construction?

Laser assisted positioning: After the total station guides the steel bars in place, a torque controlled binding tool (tightening force of 20N · m ± 5%) is used;

Micro strain compensation: Implant fiber optic sensors to monitor binding stress in real time, avoiding pre stress loss caused by over tightening;

Three dimensional adjustable fixture: used for reinforcing irregular nodes, allowing ± 15 ° angle adjustment.

How can Bar Tie Reinforcement eliminate common quality problems through technological innovation?

Anti loosening design: The self-locking buckle has a displacement of less than 0.1mm in vibration environments (traditional wire can reach 1mm);

Cold connection process: No welding throughout the entire process to avoid a decrease in the strength of the steel bars in the heat affected zone;

Full lifecycle management: Each binding point is entered into the blockchain system, which can trace construction personnel, time, and quality inspection data.

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

-

New Building Scaffolding System: Technological Innovation and Application Prospects of ScaffoldingNewsJun.19,2025

-

Double Diameter 48 Round Pipe Construction Method Using Light Steel Keel Knife Instead of Traditional Reinforcement ApplicationNewsJun.19,2025

-

Application of Square Column Reinforcement in Wall and Top StructureNewsJun.19,2025

-

Activo Scaffolding: Effective Development Practice Based on Reasonable Template Design and Supporting System ConfigurationNewsJun.19,2025

-

Optimizing Structures with Square Column ReinforcementNewsJun.10,2025

-

Maximizing Construction Efficiency with Essential Scaffolding ComponentsNewsJun.10,2025