Fév . 16, 2025 14:03

Back to list

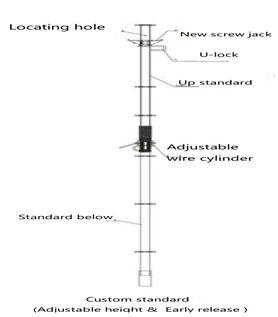

35mm scaffold pole

When it comes to versatile and reliable construction solutions, few components are as indispensable as the 35mm scaffold pole. These robust pieces of equipment are integral to the scaffolding assemblies, providing safety, efficiency, and stability on work sites everywhere. Their value in construction cannot be overstated, and understanding their use and advantages is crucial for any professional in the field.

Authority in the construction industry is grounded in the use of proven equipment, and the 35mm scaffold pole has a long-standing reputation as a trustworthy tool. Industry standards often cite the dimensions and material specifications of such poles as benchmarks for safety and performance. Their widespread use across numerous high-profile projects solidifies their status as a preferred choice among construction professionals. This universal acceptance by engineers, safety inspectors, and site managers alike serves as a testament to the pole's reliability and effectiveness. For trustworthiness, the 35mm scaffold pole stands out due to its consistent quality and performance. Manufacturers adhere to stringent quality control processes to ensure each pole meets rigorous safety and durability standards. The confidence that construction teams place in these poles is a reflection of this reliable manufacturing. Furthermore, these poles are routinely tested under various conditions to certify their strength and resilience, providing peace of mind for all stakeholders involved in a construction project. In conclusion, the 35mm scaffold pole is not merely a piece of equipment but a cornerstone in the realm of construction safety and efficiency. Its design, material integrity, and usability make it an irreplaceable component of modern scaffolding systems. Whether you are a site manager looking to ensure compliance and safety, or an engineer needing dependable materials for innovative projects, the 35mm scaffold pole is a choice that embodies excellence in construction standards.

Authority in the construction industry is grounded in the use of proven equipment, and the 35mm scaffold pole has a long-standing reputation as a trustworthy tool. Industry standards often cite the dimensions and material specifications of such poles as benchmarks for safety and performance. Their widespread use across numerous high-profile projects solidifies their status as a preferred choice among construction professionals. This universal acceptance by engineers, safety inspectors, and site managers alike serves as a testament to the pole's reliability and effectiveness. For trustworthiness, the 35mm scaffold pole stands out due to its consistent quality and performance. Manufacturers adhere to stringent quality control processes to ensure each pole meets rigorous safety and durability standards. The confidence that construction teams place in these poles is a reflection of this reliable manufacturing. Furthermore, these poles are routinely tested under various conditions to certify their strength and resilience, providing peace of mind for all stakeholders involved in a construction project. In conclusion, the 35mm scaffold pole is not merely a piece of equipment but a cornerstone in the realm of construction safety and efficiency. Its design, material integrity, and usability make it an irreplaceable component of modern scaffolding systems. Whether you are a site manager looking to ensure compliance and safety, or an engineer needing dependable materials for innovative projects, the 35mm scaffold pole is a choice that embodies excellence in construction standards.

Share

Next:

Latest news

-

Top Scaffolding Solutions for Every Construction ProjectNewsApr.21,2025

-

Scaffolding Solutions for Every ProjectNewsApr.21,2025

-

Innovative Construction Solutions for a Stronger FutureNewsApr.21,2025

-

Essential Steel Keel Solutions for Maximum Protection and PerformanceNewsApr.21,2025

-

Building a solid foundation: The importance of high-quality concrete reinforcement accessoriesNewsApr.21,2025

-

Effective Reinforcement for Stronger StructuresNewsApr.21,2025

-

The Essential Role of Timber and Steel in Modern ConstructionNewsMar.10,2025

Related Products