Ene . 14, 2025 11:12

Back to list

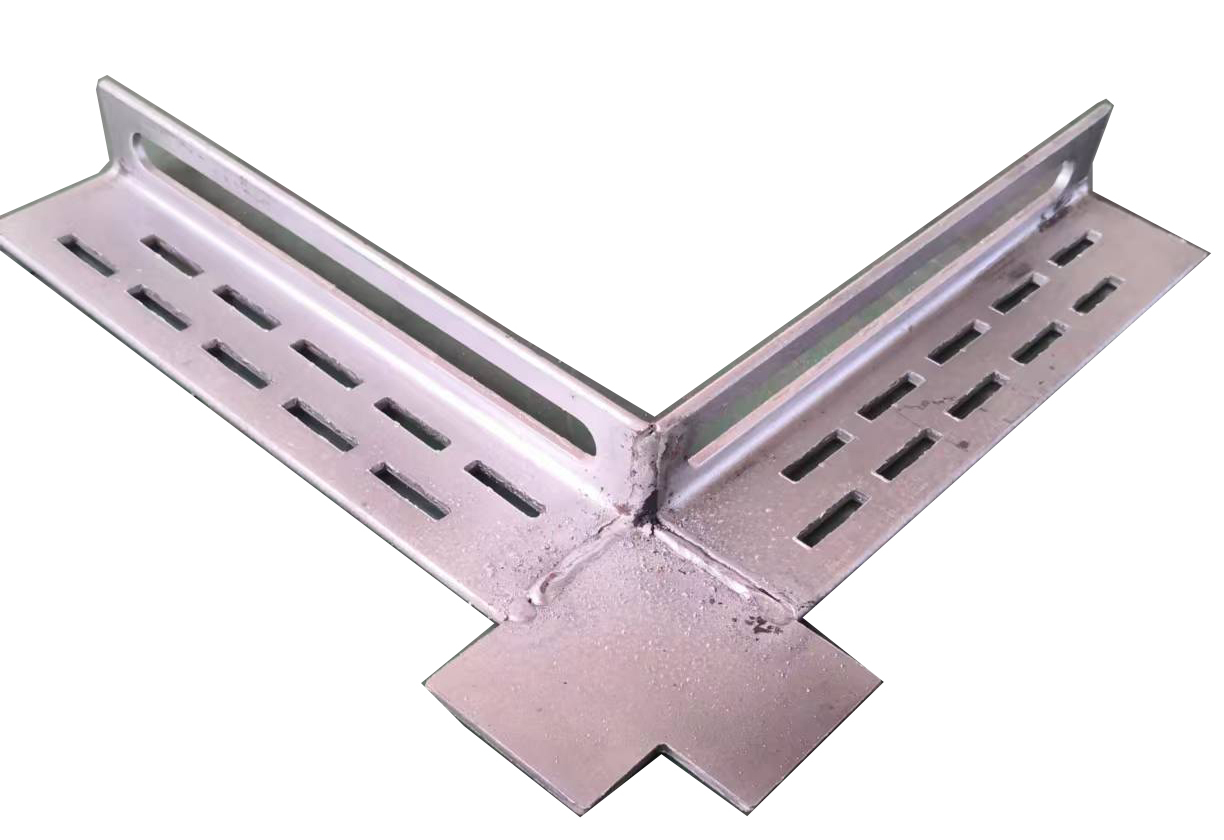

Square Column Reinforcement

Formwork for ground slabs plays an essential role in construction, providing both a mold for concrete placement and ensuring the structural integrity and surface quality of the finished slab. As such, selecting the right formwork is critical. Here we delve into the insights gained from extensive industry experience, professional expertise, and authoritative sources to guide you in making informed decisions about ground slab formwork.

Achieving excellence in formwork relies heavily on adhering to industry standards and regulations. Authoritative bodies, such as the American Concrete Institute (ACI) and the European Committee for Standardization (CEN), provide comprehensive guidelines that ensure safety and quality. It is crucial for construction professionals to stay updated with these standards to maintain compliance and deliver reliable results. Trust in formwork systems is built on proven performance over time. Case studies from leading construction projects demonstrate that selecting the right formwork can reduce cracking and enhance load-bearing capacities. Engaging with manufacturers who offer comprehensive support services and warranties is advisable, as this not only enhances trustworthiness but also aids in resolving any onsite challenges that may arise during the project. Innovative technologies continue to revolutionize formwork design and deployment. The use of self-compacting concrete (SCC) compatible formwork minimizes labor and improves finish quality by eliminating the need for mechanical vibration. Additionally, eco-friendly formwork solutions made from recycled materials are gaining popularity, aligning with growing environmental consciousness within the construction industry. In conclusion, the right formwork for ground slabs is a blend of material choice, system efficiency, adherence to standards, and trust in manufacturer support. By focusing on these aspects, construction professionals can ensure that their projects are guided by principles of experience, expertise, authoritativeness, and trustworthiness. This not only maximizes efficiency and quality but also strengthens the structural performance of their ground slabs, paving the way for sustainable and durable construction.

Achieving excellence in formwork relies heavily on adhering to industry standards and regulations. Authoritative bodies, such as the American Concrete Institute (ACI) and the European Committee for Standardization (CEN), provide comprehensive guidelines that ensure safety and quality. It is crucial for construction professionals to stay updated with these standards to maintain compliance and deliver reliable results. Trust in formwork systems is built on proven performance over time. Case studies from leading construction projects demonstrate that selecting the right formwork can reduce cracking and enhance load-bearing capacities. Engaging with manufacturers who offer comprehensive support services and warranties is advisable, as this not only enhances trustworthiness but also aids in resolving any onsite challenges that may arise during the project. Innovative technologies continue to revolutionize formwork design and deployment. The use of self-compacting concrete (SCC) compatible formwork minimizes labor and improves finish quality by eliminating the need for mechanical vibration. Additionally, eco-friendly formwork solutions made from recycled materials are gaining popularity, aligning with growing environmental consciousness within the construction industry. In conclusion, the right formwork for ground slabs is a blend of material choice, system efficiency, adherence to standards, and trust in manufacturer support. By focusing on these aspects, construction professionals can ensure that their projects are guided by principles of experience, expertise, authoritativeness, and trustworthiness. This not only maximizes efficiency and quality but also strengthens the structural performance of their ground slabs, paving the way for sustainable and durable construction.

Share

Latest news

-

The Impact of Weather Conditions on Scaffold Platform PerformanceNewsAug.01,2025

-

The Fundamental Role of Steel Keel in Building StructuresNewsAug.01,2025

-

The Advantages of Aluminium Scaffolding for Sale in the Construction MarketNewsAug.01,2025

-

Supply Chain Optimization in Joist Reinforcement Plate ProductionNewsAug.01,2025

-

Material Grades and Their Significance in Column Rebar SelectionNewsAug.01,2025

-

How to Select the Right Timber Steel for Structural ApplicationsNewsAug.01,2025

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

Related Products