Feb . 16, 2025 02:06

Back to list

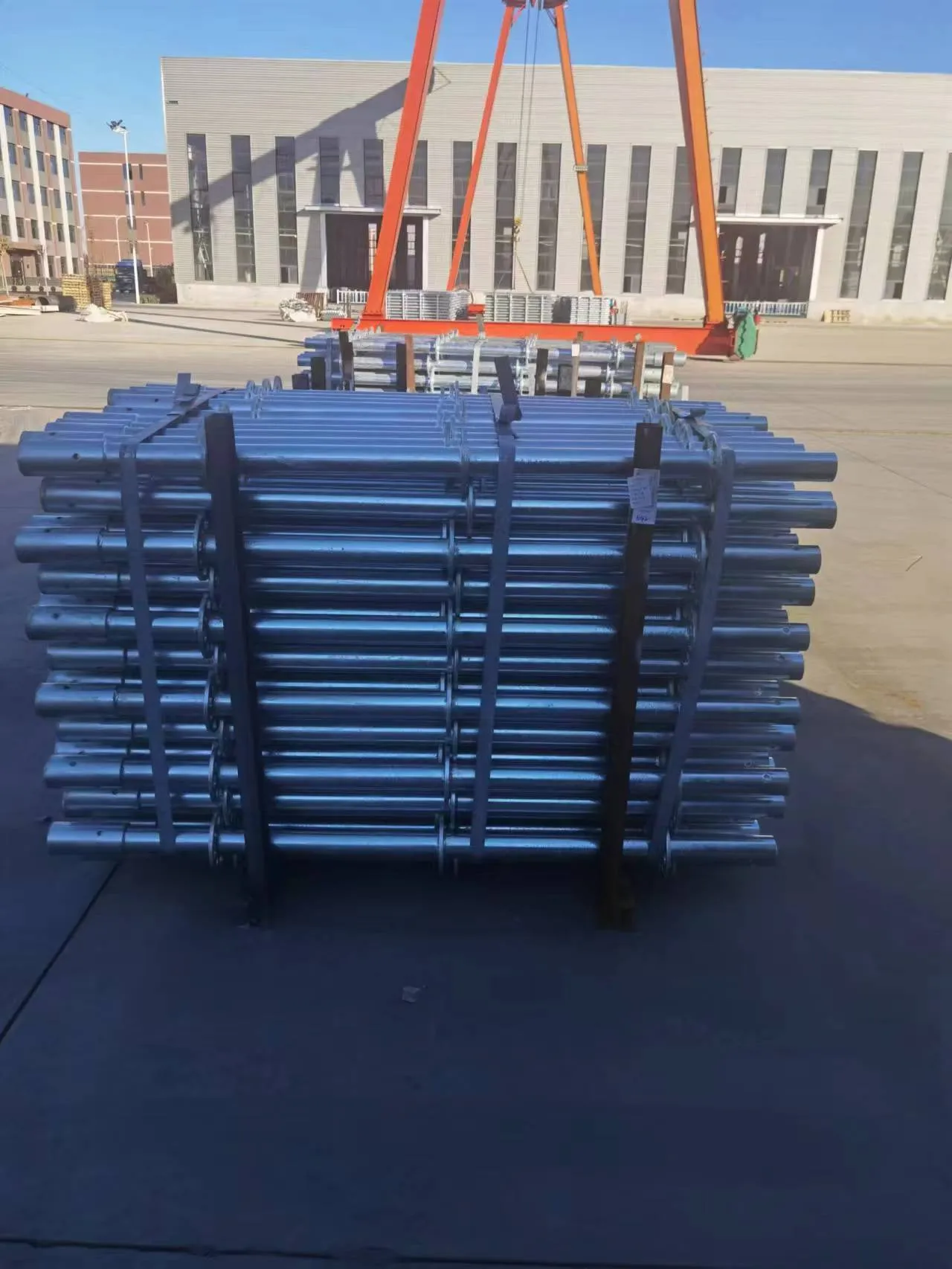

Scaffolding

In the construction industry, the importance of safety and stability cannot be overstated. A crucial component that ensures the robustness of scaffolding systems is the scaffold girder clamp. This subtle yet vital piece is pivotal in facilitating the secure connection of scaffolding tubes to steel beams, guaranteeing both worker safety and structural integrity. With years of experience in construction safety solutions, I have garnered extensive insight into the functionality, application, and significance of scaffold girder clamps.

My years of experience set me apart, particularly when assessing construction tools' expertise. Understanding the specific requirements of your project is paramount when selecting the appropriate type of scaffold girder clamp. There are swivel girder clamps, which allow for angular adjustments, and fixed girder clamps for stable, straight connections. Each type serves a different purpose and therefore must be matched accurately with project specifications to ensure safety and efficiency. Investing in high-quality scaffold girder clamps is synonymous with investing in the overall safety and efficiency of a project. An authoritative figure in the construction equipment realm knows that improper usage or installation of girder clamps can lead to catastrophic results. Thus, professional training and comprehensive understanding of these tools are essential. This encompasses knowing the weight limits, installation procedures, and inspection routines for scaffold girder clamps. Trustworthiness is built through consistent performance and reliability in the harshest working conditions, which is what top-tier scaffold girder clamps offer. Many of my clients have shared their experiences of how robust girder clamps have saved valuable time and resources by minimizing downtimes typically caused by equipment failures. This real-world testimony underscores the importance of this seemingly unassuming component. In conclusion, scaffold girder clamps might appear as mere accessories in the grand scheme of construction projects, but their impact on ensuring safe and efficient construction processes is profound. From controlling load paths to accommodating diverse structural designs, these clamps are indispensable. By maintaining a keen eye on quality and compliance, and coupling it with expert knowledge and experience, construction professionals can harness the full potential of scaffold girder clamps, laying a foundation for not just buildings, but for safe and enduring practices in construction engineering.

My years of experience set me apart, particularly when assessing construction tools' expertise. Understanding the specific requirements of your project is paramount when selecting the appropriate type of scaffold girder clamp. There are swivel girder clamps, which allow for angular adjustments, and fixed girder clamps for stable, straight connections. Each type serves a different purpose and therefore must be matched accurately with project specifications to ensure safety and efficiency. Investing in high-quality scaffold girder clamps is synonymous with investing in the overall safety and efficiency of a project. An authoritative figure in the construction equipment realm knows that improper usage or installation of girder clamps can lead to catastrophic results. Thus, professional training and comprehensive understanding of these tools are essential. This encompasses knowing the weight limits, installation procedures, and inspection routines for scaffold girder clamps. Trustworthiness is built through consistent performance and reliability in the harshest working conditions, which is what top-tier scaffold girder clamps offer. Many of my clients have shared their experiences of how robust girder clamps have saved valuable time and resources by minimizing downtimes typically caused by equipment failures. This real-world testimony underscores the importance of this seemingly unassuming component. In conclusion, scaffold girder clamps might appear as mere accessories in the grand scheme of construction projects, but their impact on ensuring safe and efficient construction processes is profound. From controlling load paths to accommodating diverse structural designs, these clamps are indispensable. By maintaining a keen eye on quality and compliance, and coupling it with expert knowledge and experience, construction professionals can harness the full potential of scaffold girder clamps, laying a foundation for not just buildings, but for safe and enduring practices in construction engineering.

Share

Next:

Latest news

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

Related Products