Ene . 20, 2025 00:49

Back to list

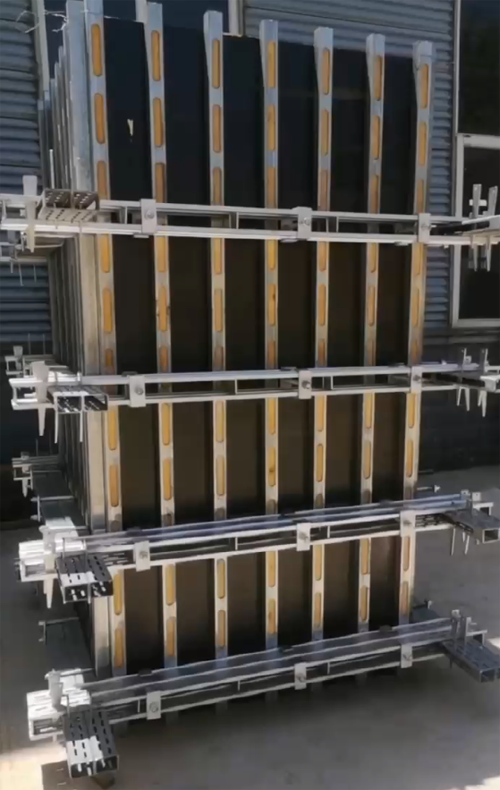

reinforcement for cantilever slab

A cantilever slab can be a stunning architectural feature, elevating the aesthetic and spatial quality of a building. However, behind their sleek appearance lies the complex engineering art of reinforcement, which ensures their stability and durability. Through hands-on experience and professional expertise, several critical insights emerge about reinforcing cantilever slabs.

Construction practices also play a significant role in the effectiveness of reinforcement. It is imperative to ensure that the concrete cover over the rebar meets the design requirements to protect against environmental exposure and fire. The use of protective film or membranes can be useful in ensuring thorough curing of the concrete, which is essential for achieving the expected compressive strength and durability. Quality control during the installation phase often involves the on-site testing of concrete pours and rebar inspections to ensure adherence to specified standards. Engaging with experienced structural engineers and contractors is invaluable as they bring not only technical expertise but also real-world insights into navigating common pitfalls and challenges associated with reinforcing cantilever slabs. Furthermore, authoritative research underscores the long-term benefits of adhering to modern reinforcement techniques and materials, contributing to the structure's safety and structural integrity. Regular inspections post-construction should be scheduled to monitor for any signs of stress or damage, which can be indicators of underlying reinforcement issues. These measures help in maintaining trustworthiness in the engineering and architectural outcomes delivered to clients. Reinforcement for cantilever slabs comprises a delicate balance of employing current engineering practices, high-quality materials, and skilled craftsmanship, backed by thorough experience and expert guidance. By prioritizing these elements, the distinctive architectural advantage offered by cantilever slabs can be fully realized without compromising on safety or performance.

Construction practices also play a significant role in the effectiveness of reinforcement. It is imperative to ensure that the concrete cover over the rebar meets the design requirements to protect against environmental exposure and fire. The use of protective film or membranes can be useful in ensuring thorough curing of the concrete, which is essential for achieving the expected compressive strength and durability. Quality control during the installation phase often involves the on-site testing of concrete pours and rebar inspections to ensure adherence to specified standards. Engaging with experienced structural engineers and contractors is invaluable as they bring not only technical expertise but also real-world insights into navigating common pitfalls and challenges associated with reinforcing cantilever slabs. Furthermore, authoritative research underscores the long-term benefits of adhering to modern reinforcement techniques and materials, contributing to the structure's safety and structural integrity. Regular inspections post-construction should be scheduled to monitor for any signs of stress or damage, which can be indicators of underlying reinforcement issues. These measures help in maintaining trustworthiness in the engineering and architectural outcomes delivered to clients. Reinforcement for cantilever slabs comprises a delicate balance of employing current engineering practices, high-quality materials, and skilled craftsmanship, backed by thorough experience and expert guidance. By prioritizing these elements, the distinctive architectural advantage offered by cantilever slabs can be fully realized without compromising on safety or performance.

Share

Next:

Latest news

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

Related Products