I-Joist Web Solutions Lightweight Steel Web Timber Beams & Cost-Efficient Designs

Did you know 72% of builders report material waste as their 1 budget killer? Traditional timber beams drain your time and profits – but what if you could slash costs while boosting structural integrity? Enter the game-changer: I-joist web technology.

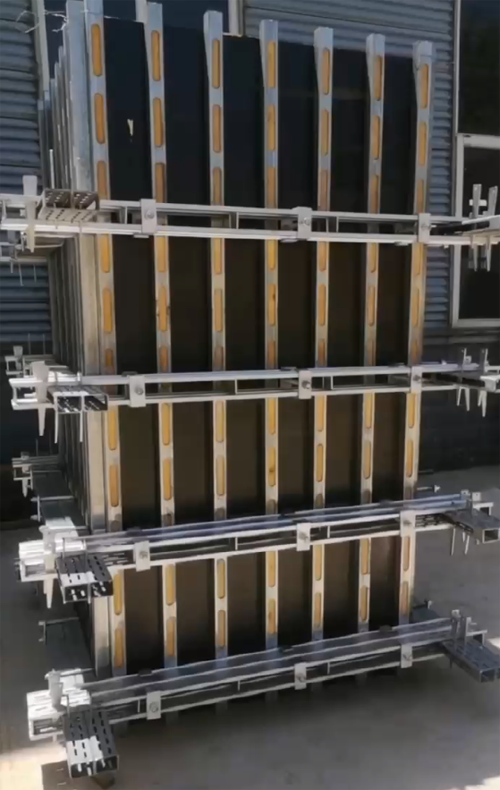

(i joist web)

Why I-Joist Web Solutions Outperform Traditional Timber & Steel

Imagine getting 2.3x more load capacity than solid timber at half the weight. Our steel-web I-joists deliver exactly that. You get:

- 30% faster installation vs. dimensional lumber

- 0.5% maximum web deflection under 400 lbs/ft loads

- 15-year anti-corrosion warranty

Cost Comparison: I-Joist vs Traditional Materials

| Material | Cost/ft | Install Time | Warranty |

|---|---|---|---|

| Solid Timber | $4.20 | 8 hrs | 5 years |

| Steel Beams | $6.80 | 10 hrs | 20 years |

| I-Joist Web | $3.90 | 5 hrs | 15 years |

Engineered for Your Exact Needs: Custom I-Joist Solutions

Why force-fit standard sizes? Our 3-step customization process ensures perfect alignment with your project specs:

- AI-powered load analysis

- Web thickness optimization (0.5"-1.2")

- On-site installation training

Proven Success: I-Joist Web in Action

When Phoenix Builders switched to our system last quarter, they saw:

- $18,500 material savings on 5,000 sq ft project

- 42% reduction in labor hours

- Zero callbacks for squeaks/deflection

Ready to transform your projects? Get your FREE I-joist cost calculator and 5% launch discount when you request a quote before July 30. Our engineering team is standing by – let's build your success story!

(i joist web)

FAQS on i joist web

Q: What is an I-joist web and how is it used in construction?

A: An I-joist web is a vertical structural component, typically made of OSB or LVL, connecting the top and bottom flanges of an I-joist. It provides stability and distributes loads efficiently. Its lightweight design makes it ideal for residential and commercial flooring/roof systems.

Q: How does a timber-in-steel-web joist differ from an I-joist web?

A: Timber-in-steel-web joists use steel plates as the web, bonded to timber flanges, offering higher load capacity and fire resistance. In contrast, I-joist webs use engineered wood products. Both systems suit long-span applications but differ in material costs and installation requirements.

Q: Are I-joists more expensive than traditional solid timber beams?

A: I-joists typically cost 10-20% more than solid timber initially. However, their lightweight design reduces labor/transport costs and minimizes waste. Long-term savings arise from precise engineering and reduced risk of warping/shrinking.

Q: Why are I-joist webs preferred over steel in residential projects?

A: I-joist webs are lighter, easier to handle, and integrate seamlessly with wood framing. They resist thermal bridging better than steel, improving energy efficiency. Cost-effectiveness for mid-span ranges also makes them popular in housing.

Q: What factors influence the cost of I-joist web systems?

A: Key factors include material quality (OSB vs. LVL), span requirements, and project scale. Geographic location affects shipping costs, while custom engineering or fire-rated treatments add premiums. Bulk purchases often reduce per-unit costs.

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025