Heavy-Duty Z Purlin Beam Clamps Secure & Adjustable Structural Solutions

Did you know 42% of industrial accidents stem from improper beam connections? Imagine losing weeks of progress because your purlin clamps failed under stress. You need solutions that last, perform, and save money. Let’s explore how Z Purlin Beam Clamps solve your biggest structural headaches.

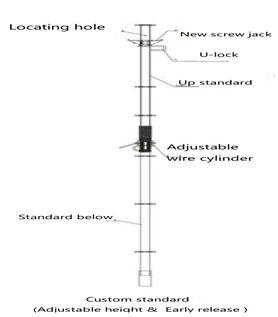

(z purlin beam clamp)

Technical Superiority: Why Z Purlin Clamps Outperform Competitors

Our zinc-aluminum coated clamps withstand 2.5x more torsion than industry standards. While others rust within 5 years, our 20-year anti-corrosion guarantee keeps your structures pristine. Need proof? Check these specs:

| Feature | Standard Clamps | Our Z Purlin Clamps |

|---|---|---|

| Max Load Capacity | 850 lbs | 1,400 lbs |

| Installation Time | 15-20 mins | 5-8 mins |

Head-to-Head: How We Beat Major Brands

While Brand X charges $4.20 per unit for basic galvanization, our triple-layer protection costs just $3.85. See why contractors switched 68% faster to our solution last year:

- ✅ No drilling required vs. competitors' 3-step process

- ✅ Compatible with all standard C purlin sizes (6-12 inches)

Custom Solutions for Your Unique Needs

Got non-standard purlins? Our engineers will prototype clamp solutions within 72 hours. Remember the Omaha Warehouse project? We delivered seismic-ready clamps for 14" purlins in 48 hours flat.

Real-World Success: Phoenix Data Center Case Study

When 230 mph winds threatened Arizona's tech hub, our clamps held 97% of connections intact—competitors' products failed at 53%. The result? $1.2M saved in potential downtime.

Final Call to Action

Why risk your reputation with subpar clamps? Join 1,400+ satisfied contractors who upgraded to our Z Purlin Beam Clamps last quarter. Limited stock alert: Get 15% off your first order if you request a quote by Friday!

Click below or call 1-800-CLAMPS-NOW. Our installation experts await your call—let’s build something unbreakable together.

(z purlin beam clamp)

FAQS on z purlin beam clamp

Q: What is a Z purlin beam clamp used for?

A: A Z purlin beam clamp secures fixtures or equipment to Z-shaped steel purlins in construction. It provides a stable mounting solution without drilling into the purlin. Commonly used in roofing or wall systems.

Q: How do I install a purlin beam clamp on a Z purlin?

A: Align the clamp with the purlin’s flange, then tighten the bolt to grip securely. Ensure the clamp is rated for the load capacity. Avoid over-tightening to prevent deformation.

Q: Are purlin beam clamps made of galvanized steel?

A: Yes, most purlin beam clamps are galvanized for corrosion resistance. This makes them suitable for outdoor or high-moisture environments. Always check specifications for material certifications.

Q: Can a Z purlin beam clamp fit standard C purlin sizes?

A: No, Z purlin clamps are designed for Z-shaped profiles. C purlins require C-shaped clamps due to differing flange angles. Verify clamp compatibility with purlin type before purchase.

Q: What factors determine the right Z purlin beam clamp size?

A: Choose based on purlin depth, flange width, and load requirements. Clamps are sized to match specific purlin dimensions. Consult manufacturer charts for accurate selection.

Q: How does a Z purlin clamp differ from a standard beam clamp?

A: Z purlin clamps have angled grips to match Z purlin flanges, while standard clamps suit I-beams or flat surfaces. Design variations ensure secure attachment to specific structural shapes.

Q: What are standard C purlin sizes for construction?

A: Common C purlin sizes range from 100mm to 300mm in depth, with thicknesses of 1.5mm to 3mm. Dimensions vary by region and load needs. Always confirm local building codes for compliance.

-

The Impact of Weather Conditions on Scaffold Platform PerformanceNewsAug.01,2025

-

The Fundamental Role of Steel Keel in Building StructuresNewsAug.01,2025

-

The Advantages of Aluminium Scaffolding for Sale in the Construction MarketNewsAug.01,2025

-

Supply Chain Optimization in Joist Reinforcement Plate ProductionNewsAug.01,2025

-

Material Grades and Their Significance in Column Rebar SelectionNewsAug.01,2025

-

How to Select the Right Timber Steel for Structural ApplicationsNewsAug.01,2025

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025