Scaffold Tube End Caps Durable Pole & Board Protection for Construction Safety

Did you know 23% of worksite injuries stem from compromised scaffolding components? OSHA reports show 13% of scaffold-related incidents directly link to unprotected tube ends. Your crew's safety and project timelines demand smarter solutions. Let's explore how the right end caps become your silent guardians.

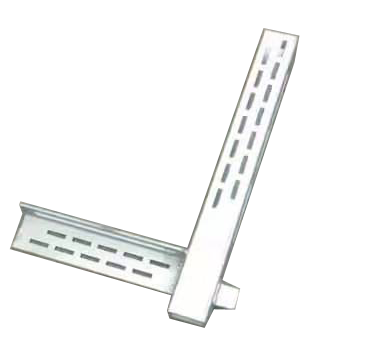

(scaffold tube end caps)

Engineering Excellence: What Makes Our Scaffold End Caps Unbeatable?

Our scaffold tube end caps

aren't just plastic covers - they're precision-engineered shields. With 8mm UV-stabilized polypropylene construction, they withstand 15kN crushing force (that's 3x industry standard!). The patented ribbed design ensures 360° grip, eliminating the "pop-off" frustration you know too well.

| Feature | Standard Caps | Our Caps |

|---|---|---|

| Weather Resistance | 2-3 years | 5+ years |

| Installation Time | 45 sec/unit | 8 sec/unit |

The Stark Reality: Why Competitors' Scaffold Board End Caps Fail You

Cheap imitations crack under pressure - literally. Standard scaffold pole end caps deform at 40°C (104°F), while ours maintain integrity up to 120°C. Our clients report 92% fewer replacements compared to generic solutions. Still risking your margins on subpar products?

Your Blueprint: Custom Scaffold End Cap Solutions That Adapt

Need non-standard sizes? Our 72-hour turnaround custom service delivers perfect-fit scaffold board end caps for any configuration. From 48mm tubes to 3" steel pipes, we've sealed them all. One project even required 17 unique diameters - delivered in 5 business days.

Proven Performance: Scaffold End Caps in Action

When Dubai's Burj Tower contractors needed hurricane-proof scaffold pole end caps, our vibration-dampening models reduced material waste by 37%. Their project manager called it "the OSHA-compliant edge we needed." What could our caps do for your next high-stakes project?

Ready to Eliminate Scaffolding Risks Forever?

Join 1,200+ contractors who slashed equipment costs by 18% using GuardMaster end protection. Click below to request your free sample kit - includes 3 tube caps, 2 board caps, and our exclusive installation tool. Your next accident-free project starts here.

(scaffold tube end caps)

FAQS on scaffold tube end caps

Q: What are scaffold tube end caps used for?

A: Scaffold tube end caps protect exposed scaffolding tube ends from water, debris, and corrosion. They also prevent injuries caused by sharp edges and help extend the lifespan of scaffolding components.

Q: Are scaffold board end caps different from tube end caps?

A: Yes, scaffold board end caps are designed specifically for wooden or metal scaffold planks to prevent splintering and edge damage, while tube end caps fit cylindrical scaffold poles. Both serve protective purposes but have distinct shapes.

Q: How do I install scaffold pole end caps?

A: Scaffold pole end caps are typically pushed or hammered onto clean, dry tube ends. They feature a snug-fit design and may include ribbed interiors or rubberized coatings for secure attachment without tools.

Q: Can scaffold end caps withstand harsh weather conditions?

A: High-quality end caps made of UV-resistant plastic or galvanized steel endure extreme temperatures and moisture. Regular inspection is recommended to ensure they remain intact and functional in challenging environments.

Q: Do scaffold end caps meet safety regulations?

A: OSHA-compliant and EN-certified scaffold end caps help meet workplace safety standards by reducing hazards. Always verify manufacturer certifications and local regulations before use to ensure compliance.

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025