Jan . 30, 2025 02:06

Back to list

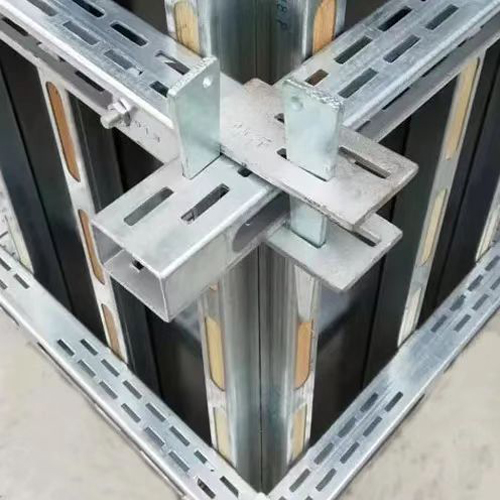

plastic construction formwork

Plastic construction formwork is rapidly becoming a key component in the modern construction industry, offering a blend of innovation, efficiency, and sustainability. Unlike traditional materials, such as wood or steel, plastic formwork provides a host of advantages that are particularly appealing to builders and engineers seeking both cost-effective and environmentally friendly solutions.

As for trustworthiness, plastic formwork satisfies several sustainability criteria, building confidence among both builders and end-users. The material is often made from recycled plastics, aligning with global efforts to reduce waste and promote recycling. Moreover, the reusability of plastic formworks is another significant advantage, as they can often be used repeatedly over many projects without a loss of integrity or performance. This not only reduces waste but also contributes to substantial cost savings over time. The sustainability factor of plastic construction formwork further extends to energy efficiency. During production, plastic formworks typically require less energy than traditional materials. Furthermore, their lightweight nature reduces transportation fuel consumption, lowering the carbon footprint of construction projects. This aligns with global environmental standards and provides a compelling argument for their increased adoption in green building practices. In conclusion, as the construction industry continually seeks ways to innovate and enhance building practices, plastic construction formwork emerges as a strong contender. It offers a combination of ease of use, durability, cost-effectiveness, and eco-friendliness that traditional materials cannot match. Whether focusing on large-scale infrastructure projects or smaller commercial developments, builders who leverage plastic formwork are poised to experience superior outcomes while actively contributing to a more sustainable future. As these benefits become more widely recognized, the adoption of plastic formwork is likely to increase, solidifying its role as a transformative force in the construction landscape.

As for trustworthiness, plastic formwork satisfies several sustainability criteria, building confidence among both builders and end-users. The material is often made from recycled plastics, aligning with global efforts to reduce waste and promote recycling. Moreover, the reusability of plastic formworks is another significant advantage, as they can often be used repeatedly over many projects without a loss of integrity or performance. This not only reduces waste but also contributes to substantial cost savings over time. The sustainability factor of plastic construction formwork further extends to energy efficiency. During production, plastic formworks typically require less energy than traditional materials. Furthermore, their lightweight nature reduces transportation fuel consumption, lowering the carbon footprint of construction projects. This aligns with global environmental standards and provides a compelling argument for their increased adoption in green building practices. In conclusion, as the construction industry continually seeks ways to innovate and enhance building practices, plastic construction formwork emerges as a strong contender. It offers a combination of ease of use, durability, cost-effectiveness, and eco-friendliness that traditional materials cannot match. Whether focusing on large-scale infrastructure projects or smaller commercial developments, builders who leverage plastic formwork are poised to experience superior outcomes while actively contributing to a more sustainable future. As these benefits become more widely recognized, the adoption of plastic formwork is likely to increase, solidifying its role as a transformative force in the construction landscape.

Share

Next:

Latest news

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

Related Products