Jan . 14, 2025 10:43

Back to list

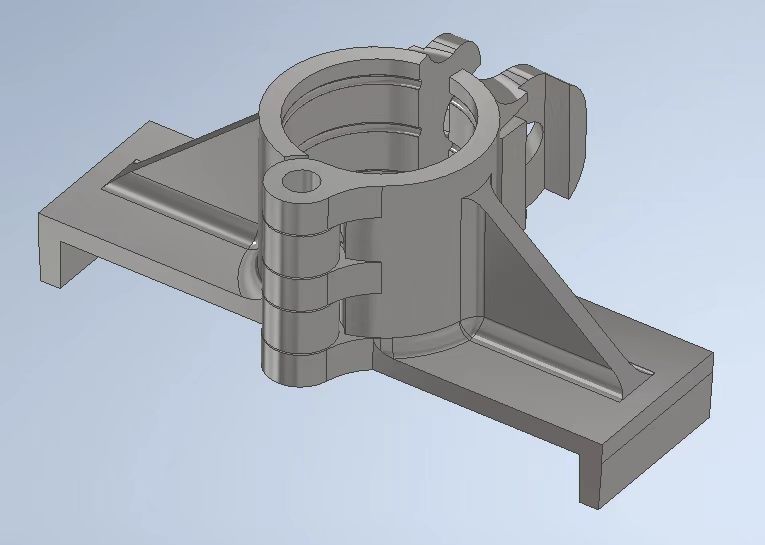

concrete pad formwork

Concrete pad formwork plays a pivotal role in the construction industry, acting as a critical component in the successful completion of various projects. The importance of proper formwork setup is often underestimated but contributes crucially to the stability, durability, and accuracy of a concrete structure. Drawing from decades of experience, I am excited to share insights and best practices that establish a solid foundation for any ambitious build.

In areas prone to environmental challenges, such as extreme temperatures or moisture conditions, selecting trustworthy formwork solutions mitigates potential complications during the curing process. For instance, innovative use of moisture-resistant coatings on formwork materials can significantly enhance performance in damp locales, ensuring that desired outcomes align with initial design intentions. This authority in formwork selection and treatment reassures clients and stakeholders of project reliability under varying climatic pressures. The credibility of a construction project traces back to the execution of its preparatory stages. By leveraging industry best practices and committing to continuous innovation in formwork technology, we can ensure not only the successful pouring of concrete pads but also the sustainable realization of architectural visions. Investing in high-quality formwork solutions with proven reliability and adaptability underpins a commitment to excellence in construction practice and project outcomes. In conclusion, concrete pad formwork is not merely about shaping concrete; it is a strategic aspect of construction project management that demands an intersection of experience, expertise, authoritativeness, and trustworthiness. As the construction landscape evolves, so must our approaches and understanding of formwork systems to deliver infrastructure that meets the highest standards of quality and resilience.

In areas prone to environmental challenges, such as extreme temperatures or moisture conditions, selecting trustworthy formwork solutions mitigates potential complications during the curing process. For instance, innovative use of moisture-resistant coatings on formwork materials can significantly enhance performance in damp locales, ensuring that desired outcomes align with initial design intentions. This authority in formwork selection and treatment reassures clients and stakeholders of project reliability under varying climatic pressures. The credibility of a construction project traces back to the execution of its preparatory stages. By leveraging industry best practices and committing to continuous innovation in formwork technology, we can ensure not only the successful pouring of concrete pads but also the sustainable realization of architectural visions. Investing in high-quality formwork solutions with proven reliability and adaptability underpins a commitment to excellence in construction practice and project outcomes. In conclusion, concrete pad formwork is not merely about shaping concrete; it is a strategic aspect of construction project management that demands an intersection of experience, expertise, authoritativeness, and trustworthiness. As the construction landscape evolves, so must our approaches and understanding of formwork systems to deliver infrastructure that meets the highest standards of quality and resilience.

Share

Next:

Latest news

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

Related Products