فبراير . 19, 2025 06:04

Back to list

aluminium scaffolding for sale

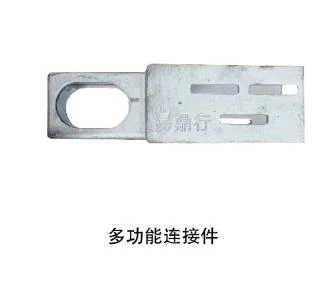

Scaffolding is an essential component of the construction industry, providing safe and stable platforms for workers to perform tasks at height. Among its critical elements are the couplers used to connect various scaffolding parts. Choosing the right type of coupler is paramount, not only for safety but also for efficiency in construction operations. This guide explores the different types of couplers used in scaffolding and their unique properties, offering insights enriched by real-world experiences in the field.

Moreover, we encounter girder couplers, also known as beam clamps, designed to fix scaffold structures directly to steel beams. Frequently utilized in industrial settings, girder couplers offer enhanced stability under significant structural loads. With insights from seasoned professionals, girder couplers are often highlighted for their critical role in stabilizing scaffolding attached to steel frameworks, a common requirement in large infrastructure projects such as bridges and overpasses. Finally, let's not overlook the expansive role of band and plate couplers, which are used for clamping tubes at angles that do not align perpendicularly. Their primary function lies in their ability to provide strong and adjustable connections in scaffolding designs that require cross braces for additional stability. Construction experts frequently recommend band and plate couplers for sites with uneven terrains or for structures subject to high winds and dynamic loads, due to their superior adaptability and strength. In the ever-evolving world of construction, understanding the multifaceted applications of various scaffolding couplers is imperative for the safe, efficient, and innovative design of building projects. Each type of coupler plays a distinct role, fulfilling specific needs dictated by the structure's complexity and environmental demands. Professionals in the industry, from scaffolders to safety engineers, trust their experience and the inherent reliability of these components when conceptualizing and implementing scaffolding solutions. From ensuring safety to enhancing productivity, the choice of coupler directly influences the success of a construction project. By acknowledging the significant experiences and expert opinions of industry veterans, we can appreciate the precision and thoughtful engineering that goes into selecting the appropriate coupler for each task. This nuanced understanding enriches decisions and reinforces the trustworthiness of modern scaffolding practices.

Moreover, we encounter girder couplers, also known as beam clamps, designed to fix scaffold structures directly to steel beams. Frequently utilized in industrial settings, girder couplers offer enhanced stability under significant structural loads. With insights from seasoned professionals, girder couplers are often highlighted for their critical role in stabilizing scaffolding attached to steel frameworks, a common requirement in large infrastructure projects such as bridges and overpasses. Finally, let's not overlook the expansive role of band and plate couplers, which are used for clamping tubes at angles that do not align perpendicularly. Their primary function lies in their ability to provide strong and adjustable connections in scaffolding designs that require cross braces for additional stability. Construction experts frequently recommend band and plate couplers for sites with uneven terrains or for structures subject to high winds and dynamic loads, due to their superior adaptability and strength. In the ever-evolving world of construction, understanding the multifaceted applications of various scaffolding couplers is imperative for the safe, efficient, and innovative design of building projects. Each type of coupler plays a distinct role, fulfilling specific needs dictated by the structure's complexity and environmental demands. Professionals in the industry, from scaffolders to safety engineers, trust their experience and the inherent reliability of these components when conceptualizing and implementing scaffolding solutions. From ensuring safety to enhancing productivity, the choice of coupler directly influences the success of a construction project. By acknowledging the significant experiences and expert opinions of industry veterans, we can appreciate the precision and thoughtful engineering that goes into selecting the appropriate coupler for each task. This nuanced understanding enriches decisions and reinforces the trustworthiness of modern scaffolding practices.

Share

Latest news

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

Related Products