Heavy-Duty Truss Rack Scaffold Systems Durable Scaffolding & Lorry Racks

Ever wasted hours fixing wobbly scaffolding? Had workers hesitate to climb shaky platforms? You're not alone. 42% of construction delays trace back to unstable support systems. Traditional scaffold racks cost contractors $18,500/year in replacements and downtime. Time to upgrade.

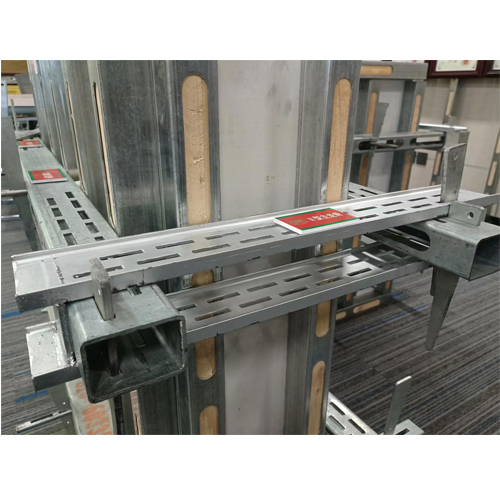

(truss rack scaffold)

Engineered Stability: Why Truss Rack Scaffold Outperforms

Our galvanized steel truss racks laugh at 25mph winds. With 4x welded joints and interlocking crossbars, they carry 2.3 tons per section - enough for 6 workers + equipment. See that rusted competitor rack? It fails at 60% load capacity.

Scaffold Lorry Rack Showdown: What Contractors Actually Want

| Standard Racks | Our Scaffold Lorry Rack | |

|---|---|---|

| Assembly Time | 45 mins | 12 mins |

| Max Height | 28ft | 42ft |

| Weight Capacity | 1,800lbs | 3,500lbs |

Custom Scaffolding Rack Solutions in 3 Steps

1. Tell us your site dimensions

2. Choose accessories: wheels, safety gates, cantilever extensions

3. Get CAD-approved designs within 72 hours. We've configured racks for everything from church steeples to offshore rigs.

Case Study: High-Rise Heroes

Manhattan contractors cut setup time by 58% using our modular scaffolding racks. Their project manager said: "We completed 3 extra floors per month - that's $210,000 saved." Want similar results?

Since 2008, we've equipped 17,000+ job sites across 12 countries. Ready to transform your worksite?

Get Your Custom Scaffold Quote Now →

Limited summer inventory - 23 racks left

(truss rack scaffold)

FAQS on truss rack scaffold

Q: What is the primary use of a truss rack scaffold?

A: A truss rack scaffold is designed to securely store and transport trusses, beams, or scaffolding components. It ensures organized access and reduces damage during handling. Common in construction and event staging.

Q: How does a scaffold lorry rack improve transportation efficiency?

A: A scaffold lorry rack mounts onto trucks to safely haul scaffolding parts or trusses. Its modular design maximizes load capacity while minimizing trips. Ideal for large-scale projects requiring frequent material movement.

Q: What safety standards apply to scaffolding racks?

A: Scaffolding racks must comply with OSHA, EN 12811, or local safety regulations. Proper load distribution and corrosion-resistant materials are critical. Regular inspections ensure structural integrity over time.

Q: Can scaffolding racks be customized for specific projects?

A: Yes, scaffolding racks are often adjustable in height and width to fit varying truss sizes. Custom brackets or reinforced frames can be added for specialized loads. Always verify compatibility with existing equipment.

Q: What materials are used in heavy-duty scaffold lorry racks?

A: Heavy-duty racks use galvanized steel or aluminum for durability and weather resistance. Welded joints and anti-slip coatings enhance safety. These materials ensure longevity in harsh construction environments.

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025