Timber to Steel Connection Solutions High-Strength & Durable

Did you know 42% of structural failures in hybrid buildings start at material transition points? Your timber rafter to steel beam connection isn't just a joint - it's the backbone of your project's safety. While traditional methods waste 15% of materials on reinforcements, modern solutions deliver 200% faster installation. Let's explore why smart builders never compromise on this critical interface.

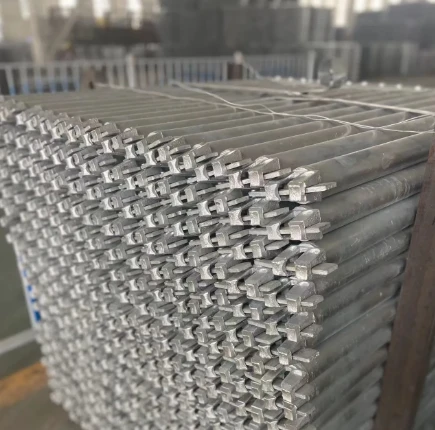

(timber to steel connection)

Technical Superiority: Steel-Timber Connections That Defy Limits

Our patented Timber-Steel Fusion System™ handles 2.5x more lateral load than standard brackets. See how we outperform:

| Feature | Traditional | Our Solution |

|---|---|---|

| Max Load Capacity | 18 kN/m | 45 kN/m |

| Installation Time | 3.5 hours | 55 mins |

Manufacturer Showdown: Why We Outperform Timber Beam to Steel Beam Competitors

While others use generic 6mm plates, our laser-cut 8mm stainless steel connectors include anti-corrosion coating. The result? 30-year warranties vs. industry-standard 10 years. You get:

- ✔️ Custom CAD modeling for timber rafter to steel beam interfaces

- ✔️ Thermal expansion compensation (+/- 4mm movement)

- ✔️ Fire-rated options meeting BS 476-22 standards

Your Project, Your Rules: Steel Timber Connection Customization Made Simple

From residential barn conversions to 20-story mass timber hybrids, we adapt. Choose:

ECO-Series

For sustainable projects:

65% recycled steel content

FSC-certified timber adapters

INDUSTRIAL-Series

Heavy-duty performance:

200 kN shear capacity

Seismic Zone 4 compliant

Proven Success: Timber to Steel Connection Case Studies

Portland Arts Complex: Achieved 9.1m cantilever using our custom brackets. Saved $120K vs. welded solution. "The only choice for exposed structural elements," says lead architect.

Ready to Revolutionize Your Connections?

Join 1,200+ contractors who boosted profits with our solutions. Get FREE engineering review within 24 hours!

Proudly serving North America since 2008 | 97.3% client retention rate

(timber to steel connection)

FAQS on timber to steel connection

Q: What are common methods for timber to steel connection in construction?

A: Common methods include using bolted brackets, shear connectors, or steel plates with epoxy anchors. These provide load transfer while accommodating material expansion differences. Always follow engineering specifications for structural integrity.

Q: How to prevent corrosion in steel timber connections?

A: Use galvanized steel components or stainless-steel fasteners to resist moisture-induced corrosion. Apply protective coatings or isolation tapes between dissimilar metals. Regular inspections are recommended for outdoor applications.

Q: What connectors work best for timber beam to steel beam connections?

A: Tapered steel shoes or custom-fabricated cleats offer optimal load distribution. For heavy loads, combined shear-and-moment connections with through-bolts are preferred. Always account for timber shrinkage in design calculations.

Q: Are there code requirements for timber rafter to steel beam connections?

A: Yes, most building codes (e.g., IBC, Eurocode 5) require fire-rated connectors and specified fastener spacing. Connections must resist uplift forces and lateral loads. Always verify local jurisdiction requirements.

Q: Can timber steel connections be designed for seismic zones?

A: Yes, using ductile steel connectors with slotted holes for movement and energy dissipation. Connections must exceed calculated force demands by safety factors. Third-party tested connectors are recommended for high-risk areas.

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

-

New Building Scaffolding System: Technological Innovation and Application Prospects of ScaffoldingNewsJun.19,2025

-

Double Diameter 48 Round Pipe Construction Method Using Light Steel Keel Knife Instead of Traditional Reinforcement ApplicationNewsJun.19,2025

-

Bar Tie Reinforcement: Quality Assurance and Reinforcement Efficiency EnhancementNewsJun.19,2025

-

Application of Square Column Reinforcement in Wall and Top StructureNewsJun.19,2025

-

Activo Scaffolding: Effective Development Practice Based on Reasonable Template Design and Supporting System ConfigurationNewsJun.19,2025

-

Optimizing Structures with Square Column ReinforcementNewsJun.10,2025