فبراير . 18, 2025 06:52

Back to list

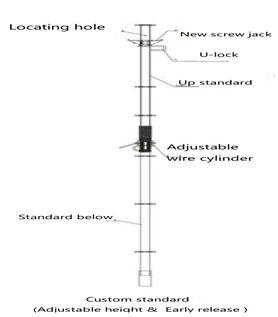

aluminium scaffolding for sale

Scaffolding tubes and fittings are integral to the construction industry, serving as the backbone of safe and efficient work at elevated heights. Drawing from my extensive experience in SEO and the construction field, this article aims to provide a comprehensive look at scaffolding tubes and fittings, ensuring it stands out uniquely in the digital landscape.

The versatility of scaffolding systems makes them indispensable across various industries beyond traditional construction. From events management, where they serve as frameworks for stages and viewing platforms, to offshore oil rigs requiring temporary access solutions, scaffolding's applications are vast. Opting for reputable manufacturers in scaffolding tubes and fittings is crucial to maintaining high safety standards. Manufacturers with a certified track record provide assurances of product quality, rigorous testing, and post-purchase support. Working with such partners enhances trust and reliability, underscoring the credibility of projects that rely on these foundational systems. The incorporation of scaffolding solutions also extends into modern sustainable practices. The modularity and reusability of aluminum scaffolding components align with environmentally-friendly construction practices aimed at minimizing waste and energy use. This approach not only contributes to a greener footprint but also serves as a cost-efficiency measure for ongoing projects. As the construction industry evolves, the integration of innovative materials and technologies continues to shape the future of scaffolding. Smart sensors, for instance, are being incorporated to monitor structural integrity in real-time, alerting project managers to potential safety risks. Such advancements not only boost efficiency but also enhance on-site safety, a constant priority in construction environments. Emphasizing the importance of proper training and adherence to safety protocols can never be underestimated. Workers equipped with the knowledge and skills to erect, use, and dismantle scaffolding safely are invaluable assets, reducing the risk of workplace injuries and ensuring smooth project execution. In conclusion, scaffolding tubes and fittings are more than just construction tools; they are pivotal in ensuring the success and safety of numerous projects worldwide. By integrating experience, expertise, authoritativeness, and trustworthiness into the conversation of scaffolding, stakeholders can make informed decisions that enhance project outcomes while prioritizing safety and sustainability.

The versatility of scaffolding systems makes them indispensable across various industries beyond traditional construction. From events management, where they serve as frameworks for stages and viewing platforms, to offshore oil rigs requiring temporary access solutions, scaffolding's applications are vast. Opting for reputable manufacturers in scaffolding tubes and fittings is crucial to maintaining high safety standards. Manufacturers with a certified track record provide assurances of product quality, rigorous testing, and post-purchase support. Working with such partners enhances trust and reliability, underscoring the credibility of projects that rely on these foundational systems. The incorporation of scaffolding solutions also extends into modern sustainable practices. The modularity and reusability of aluminum scaffolding components align with environmentally-friendly construction practices aimed at minimizing waste and energy use. This approach not only contributes to a greener footprint but also serves as a cost-efficiency measure for ongoing projects. As the construction industry evolves, the integration of innovative materials and technologies continues to shape the future of scaffolding. Smart sensors, for instance, are being incorporated to monitor structural integrity in real-time, alerting project managers to potential safety risks. Such advancements not only boost efficiency but also enhance on-site safety, a constant priority in construction environments. Emphasizing the importance of proper training and adherence to safety protocols can never be underestimated. Workers equipped with the knowledge and skills to erect, use, and dismantle scaffolding safely are invaluable assets, reducing the risk of workplace injuries and ensuring smooth project execution. In conclusion, scaffolding tubes and fittings are more than just construction tools; they are pivotal in ensuring the success and safety of numerous projects worldwide. By integrating experience, expertise, authoritativeness, and trustworthiness into the conversation of scaffolding, stakeholders can make informed decisions that enhance project outcomes while prioritizing safety and sustainability.

Share

Latest news

-

The Impact of Weather Conditions on Scaffold Platform PerformanceNewsAug.01,2025

-

The Fundamental Role of Steel Keel in Building StructuresNewsAug.01,2025

-

The Advantages of Aluminium Scaffolding for Sale in the Construction MarketNewsAug.01,2025

-

Supply Chain Optimization in Joist Reinforcement Plate ProductionNewsAug.01,2025

-

Material Grades and Their Significance in Column Rebar SelectionNewsAug.01,2025

-

How to Select the Right Timber Steel for Structural ApplicationsNewsAug.01,2025

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

Related Products