High-Quality Steel Keel & Light Steel Keel Solutions

Unveiling the Backbone of Modern Construction: The Keel Steel Revolution

In the rapidly evolving landscape of construction and industrial applications, the choice of foundational materials dictates the longevity, safety, and efficiency of any structure. Among these, the **steel keel** stands out as a fundamental component, offering unparalleled strength, versatility, and structural integrity. Often unseen, yet indispensable, the **steel keel** forms the skeleton for various building systems, from drywall partitions to complex roofing and ceiling structures, and even plays a critical role in specialized industrial frameworks.

This comprehensive guide delves deep into the world of **Keel Steel** (Product Name: Keel Steel), exploring its critical importance, technological advancements, diverse applications, and the distinct advantages it brings to modern engineering challenges. We aim to provide an authoritative resource for engineers, architects, contractors, and procurement specialists seeking to understand the full potential of high-quality **steel keel** solutions.

Industry Trends and the Evolution of Steel Keel Technology

The construction industry is witnessing a significant shift towards sustainable, efficient, and resilient building practices. This paradigm shift directly influences the demand for advanced materials like **steel keel**. Key trends driving this evolution include:

- Lightweighting: The increasing popularity of light steel keel systems, which offer comparable strength to heavier alternatives while reducing material consumption and transportation costs. This trend is vital for modular construction and prefabricated components.

- Enhanced Corrosion Resistance: As structures face harsher environmental conditions, the demand for materials like stainless steel keel band and galvanized **steel keel** is rising. These solutions provide extended service life and reduced maintenance, particularly in coastal or chemically aggressive environments.

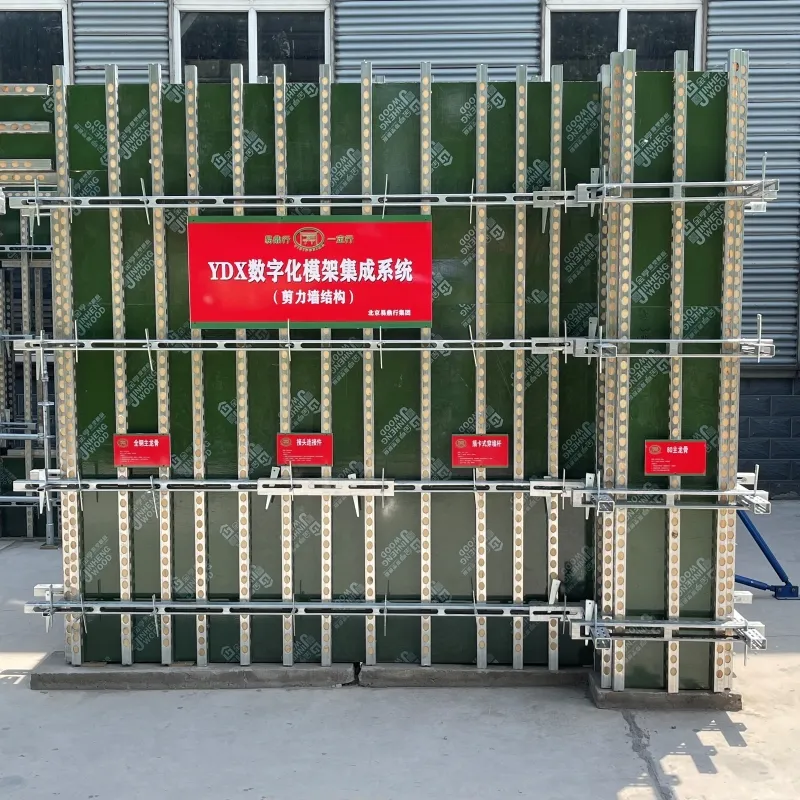

- Digital Fabrication and Precision Engineering: The integration of BIM (Building Information Modeling) and advanced manufacturing techniques (like CNC punching and roll forming) ensures highly precise **steel keel** components, minimizing on-site errors and accelerating construction timelines.

- Sustainability: Steel's recyclability makes **steel keel** an environmentally friendly choice, aligning with green building certifications and reduced carbon footprints.

Understanding the steel keel meaning in english signifies grasping its role as a fundamental load-bearing or supporting element, akin to the keel of a ship, providing stability and structure. Its versatility allows for integration into diverse architectural and engineering designs.

Technical Parameters and Specifications of Keel Steel

The performance of a **steel keel** is defined by a meticulous set of technical parameters, ensuring its suitability for specific applications. Our Keel Steel products are engineered to meet and exceed industry standards, providing superior strength, durability, and reliability. Below is a detailed table outlining typical specifications for various types of **steel keel** commonly used in construction:

| Parameter | Standard Cold-Formed Steel Keel (Galvanized) | Light Steel Keel (High-Strength Alloy) | Stainless Steel Keel Band (304/316) | Hot-Rolled Structural Steel Keel |

|---|---|---|---|---|

| Material Grade (Typical) | DX51D+Z (EN 10346), ASTM A653 G90 | Q345B/C (GB/T 1591), ASTM A572 Grade 50 | AISI 304, AISI 316 | Q235B (GB/T 700), ASTM A36 |

| Yield Strength (Min.) | 250-350 MPa (36-50 ksi) | 345-420 MPa (50-60 ksi) | 205 MPa (30 ksi) | 235 MPa (34 ksi) |

| Tensile Strength (Min.) | 330-450 MPa (48-65 ksi) | 490-550 MPa (71-80 ksi) | 515-620 MPa (75-90 ksi) | 400-550 MPa (58-80 ksi) |

| Elongation at Break (Min.) | 20-22% | 18-20% | 40-50% | 20-23% |

| Coating Type/Thickness | Hot-dip galvanized (Z275, G90) | Pre-galvanized or painted | N/A (inherent corrosion resistance) | Primer coating, hot-dip galvanized (optional) |

| Standard Profile Sizes | C-studs, U-tracks (50-150mm web) | C-channels, hat sections (75-250mm web) | Flat bars, custom profiles | I-beams, H-beams, channels, angles |

| Common Thickness Range | 0.5mm - 1.2mm | 0.7mm - 2.5mm | 1.0mm - 6.0mm | 3.0mm - 20.0mm+ |

| Corrosion Resistance | Good (depends on zinc coating) | Moderate to Good | Excellent | Low (requires protection) |

| Applicable Standards | ASTM C645, EN 14195, AS/NZS 1397 | AISI S100, Eurocode 3, GB 50018 | ASTM A240, EN 10088 | ASTM A6, EN 10025, JIS G3101 |

Expert Insight: The choice of **steel keel** material and profile is critical. For instance, in areas requiring high seismic resistance, a light steel keel with high yield strength might be preferred due to its favorable strength-to-weight ratio. For aggressive chemical environments, the superior corrosion resistance of a stainless steel keel band becomes indispensable, even if the initial cost is higher. Our team of metallurgists and structural engineers can assist in selecting the optimal specifications for your project, leveraging our deep understanding of various steel grades and their performance characteristics.

Comprehensive Manufacturing Process of Keel Steel

The production of high-quality **steel keel** involves a series of precision-engineered steps, ensuring consistency, strength, and adherence to stringent quality controls. At Formwork Reinforced, our manufacturing process for Keel Steel (Product Name: Keel Steel) is designed for efficiency, accuracy, and superior product performance.

Process Flow Diagram:

Manufacturing Expertise: Unlike traditional casting or heavy forging which are primarily for bulk, solid steel components, **steel keel** is predominantly manufactured using advanced roll-forming techniques. This cold-forming process is highly efficient, produces precise profiles with excellent surface finish, and allows for the production of light steel keel with high strength-to-weight ratios. Our state-of-the-art machinery and skilled technicians ensure every **steel keel** component adheres to the highest standards of structural integrity and longevity.

Diverse Application Scenarios of Keel Steel

The versatility of **steel keel** makes it an indispensable component across a multitude of industries and construction types. Its robust nature and adaptability allow for innovative structural solutions. Here are some key application areas:

- Building & Construction:

- Drywall Framing: **Steel keel** (C-studs and U-tracks) forms the internal skeleton for non-load-bearing walls and partitions in commercial, residential, and industrial buildings. It offers superior fire resistance, dimensional stability, and resistance to pests compared to timber.

- Ceiling Systems: Suspended ceiling grids utilize **steel keel** components to support ceiling tiles and fixtures, providing a versatile and accessible overhead system.

- Roofing Structures: Light steel keel profiles are increasingly used in lightweight roofing systems for their ease of installation and structural efficiency.

- External Cladding & Façade Systems: Specialized **steel keel** systems provide the framework for attaching exterior cladding, ensuring proper ventilation and thermal insulation.

- Industrial Applications:

- Petrochemical & Chemical Plants: For supporting pipelines, cable trays, and equipment. Stainless steel keel band is often specified here due to its excellent corrosion resistance against aggressive chemicals, ensuring long-term structural integrity and operational safety.

- Metallurgy & Mining: Used in conveyor belt structures, equipment enclosures, and non-structural supports within harsh industrial environments. The robust nature of **steel keel** stands up to demanding conditions.

- Water Supply & Drainage Infrastructure: In treatment plants and pumping stations, **steel keel** provides durable frameworks for platforms, walkways, and supporting large diameter pipes, where resistance to moisture and potential contaminants is crucial.

- Marine & Offshore: Though the term steel keel in english often refers to a ship's bottom beam, in construction, the principles of robust steel framing extend to marine structures for walkways, platforms, and non-corrosive stainless steel keel band applications.

- Specialized Structures:

- Modular Buildings: Light steel keel systems are ideal for rapid assembly and disassembly in modular and temporary structures due to their prefabrication potential.

- Renewable Energy Installations: Supporting frameworks for solar panels, wind turbine components, and related infrastructure.

- Agricultural Buildings: Cost-effective and durable structures for barns, storage facilities, and greenhouses.

Technical Advantages of Keel Steel

Choosing Keel Steel from Formwork Reinforced translates into tangible benefits for your projects, ensuring long-term performance and cost-effectiveness.

- Superior Strength-to-Weight Ratio: Especially true for light steel keel, it provides excellent structural integrity without imposing excessive dead loads, leading to lighter foundations and overall material savings.

- Exceptional Durability & Longevity: With proper galvanization or the use of stainless steel keel band, our products offer outstanding resistance to corrosion, rot, pests, and fire, ensuring a long service life of 50 years or more under normal conditions. This significantly reduces maintenance and replacement costs over the lifespan of a structure.

- Dimensional Stability & Accuracy: Unlike wood, **steel keel** does not warp, shrink, or expand significantly with changes in moisture or temperature, leading to consistently straight walls and true dimensions. Our CNC-driven manufacturing ensures precision.

- Fire Resistance: Steel is inherently non-combustible, contributing significantly to the fire safety of a building.

- Sustainability: Steel is 100% recyclable, making **steel keel** an environmentally responsible choice, aligning with modern green building standards.

- Ease of Installation: Prefabricated and precisely dimensioned **steel keel** components streamline the construction process, reducing labor costs and accelerating project timelines.

Manufacturer Comparison and Why Choose Formwork Reinforced

In a competitive market, selecting the right **steel keel** manufacturer is paramount. Formwork Reinforced distinguishes itself through a commitment to quality, innovation, and customer-centric service. While many manufacturers offer **steel keel** products, our differentiating factors include:

| Feature | Formwork Reinforced Keel Steel | Typical Competitor A | Typical Competitor B |

|---|---|---|---|

| Material Sourcing | Premium, certified coils (ASTM, EN, JIS) | Standard grade, varied sourcing | Cost-optimized, less consistent |

| Manufacturing Process | Advanced CNC Roll Forming, In-line QC | Basic Roll Forming, batch QC | Older machinery, minimal QC |

| Quality Certifications | ISO 9001:2015, ASTM, EN compliance | Basic ISO, limited product certs | No major international certs |

| Product Range | Extensive (standard, light steel keel, stainless steel keel band, custom) | Limited standard profiles | Very limited, often low-grade |

| Customization Capabilities | Full engineering support, bespoke profiles, pre-punched designs | Limited custom lengths only | None |

| Corrosion Protection | Z275/G90 Galvanization, SS grades, custom coatings | Basic Z180/G60 Galvanization | Minimal or no galvanization |

| Customer Support & Warranty | Dedicated technical team, comprehensive warranty (5-10 years) | Basic sales support, limited warranty | Minimal post-sales support |

| Lead Time (typical) | 2-4 weeks (standard), 4-6 weeks (custom) | 3-5 weeks | 5-8 weeks |

Authoritativeness & Experience: With over 15 years in the steel manufacturing industry, Formwork Reinforced has cultivated deep expertise in producing high-performance **steel keel** solutions. We are a trusted partner for major construction firms and industrial clients worldwide, evidenced by our long-standing relationships and repeat business. Our collaboration with leading material science institutes ensures our products remain at the forefront of innovation. We pride ourselves on transparent operations, adherence to international standards, and a proven track record of successful project deliveries across diverse sectors, reinforcing our position as an authoritative voice in **steel keel** manufacturing.

Customization Solutions for Your Steel Keel Needs

Recognizing that every project has unique requirements, Formwork Reinforced excels in providing bespoke **steel keel** solutions. Our engineering team works closely with clients to develop customized profiles, lengths, gauges, and finishes, ensuring optimal fit and performance.

Our customization capabilities include:

- Custom Profiles: Beyond standard C-studs, U-tracks, and hat sections, we can design and manufacture unique **steel keel** profiles tailored to specific structural demands or architectural aesthetics.

- Specific Lengths & Gauges: Producing exact lengths minimizes on-site cutting and waste, while precise gauge selection optimizes strength-to-weight and cost efficiency.

- Pre-punched & Notched Components: To facilitate faster and more accurate assembly, we can deliver **steel keel** with pre-punched holes or notches for services (e.g., electrical, plumbing) or connection points.

- Special Coatings & Finishes: From heavy-duty galvanization to powder coating or specialized anti-corrosion treatments, we offer various finishes to suit environmental exposures, including enhancing stainless steel keel band for extreme conditions.

- Material Selection: Advice and provision of specific steel grades (e.g., higher yield strength for light steel keel, specific stainless steel alloys) to meet particular structural, environmental, or chemical resistance requirements.

Our collaborative approach ensures that even the most complex **steel keel** design challenges are met with innovative and cost-effective solutions. We leverage advanced CAD/CAM software to design and simulate custom profiles, ensuring precise manufacturing and seamless integration into your project.

Real-World Application Cases and Client Success Stories

Our commitment to quality and innovation in **steel keel** manufacturing is best demonstrated through the success of our clients' projects. Here are a few illustrative examples:

- High-Rise Residential Tower, Metropolis City: For a 60-story residential complex, we supplied custom light steel keel framing for all interior non-load-bearing walls and ceiling systems. The project demanded high precision and rapid installation. Our pre-cut and pre-punched **steel keel** components reduced on-site labor by 25% and accelerated framing completion by three weeks. The project achieved LEED Gold certification, partly due to the sustainable and lightweight nature of our **Keel Steel**.

- Coastal Industrial Facility, Seaport Region: In a demanding coastal environment prone to salt spray, a major industrial facility required highly corrosion-resistant support structures for its pipework and equipment enclosures. We provided bespoke stainless steel keel band solutions (AISI 316L) which have demonstrated exceptional performance over 8 years, showing no signs of corrosion despite the aggressive marine atmosphere. This choice mitigated potential costly maintenance and downtime, showcasing the long-term value of specialized **steel keel**.

- Modular Healthcare Units, Remote Area: For a rapid deployment of modular healthcare units in a remote region, the client needed extremely durable yet lightweight framing components that could be assembled quickly. Our specialized light steel keel profiles enabled off-site fabrication of module panels, which were then transported and quickly erected on-site. The inherent strength and dimensional stability of the **steel keel** ensured the integrity of these critical temporary structures.

These cases underscore our capability to deliver reliable, high-performance **steel keel** products for diverse and challenging applications, reinforcing our position as an experienced and trustworthy partner.

Frequently Asked Questions (FAQ) about Keel Steel

To further enhance clarity and address common inquiries, we've compiled a list of frequently asked questions regarding **steel keel** and our products.

Q1: What is the typical lifespan of a galvanized **steel keel**?

A1: Under normal conditions and with proper installation, a hot-dip galvanized **steel keel** (with a Z275/G90 coating) can have a lifespan exceeding 50-70 years. In less aggressive indoor environments, it can last even longer. The zinc coating provides sacrificial protection, preventing the underlying steel from corroding.

Q2: How does light steel keel differ from traditional heavy steel sections?

A2: Light steel keel refers to thin-walled steel sections typically cold-formed from galvanized steel sheets. While traditional heavy steel sections (like I-beams, H-beams) are hot-rolled and designed for primary structural load-bearing, light steel keel is generally used for secondary framing, non-load-bearing walls, ceilings, and lightweight structures where its high strength-to-weight ratio is advantageous. The steel keel meaning in english for these lighter sections emphasizes their role as a skeletal support.

Q3: What are the primary inspection standards for Keel Steel?

A3: Our **Keel Steel** products comply with international standards such as ASTM C645 (Standard Specification for Nonstructural Steel Framing Members), EN 14195 (Drywall prefabrication systems), AISI S100 (North American Specification for the Design of Cold-Formed Steel Structural Members), and ISO 9001 for quality management systems. These standards ensure product consistency, performance, and safety.

Q4: Can stainless steel keel band be used in marine environments?

A4: Absolutely. Stainless steel keel band, particularly grades like AISI 316 or 316L, offers superior corrosion resistance in marine and other highly corrosive environments due to its molybdenum content. This makes it an ideal choice for applications exposed to salt water, chlorides, or industrial chemicals, extending the operational life of the structure significantly.

Q5: What is the typical delivery period for custom Keel Steel orders?

A5: For standard **steel keel** profiles, our typical delivery period is 2-4 weeks, depending on order volume and destination. For custom-engineered **steel keel** solutions, the lead time usually ranges from 4-6 weeks, allowing for design, tooling adjustments, and specialized manufacturing processes. We communicate clear timelines at the time of quotation.

Q6: What kind of warranty does Formwork Reinforced offer on its Keel Steel products?

A6: Formwork Reinforced stands behind the quality of its Keel Steel. We offer a comprehensive warranty covering manufacturing defects and material integrity for 5-10 years, depending on the product type and application. Specific warranty details are provided with each quotation and order, reflecting our confidence in the longevity and performance of our **steel keel** products.

Q7: How do I get technical support for Keel Steel installation or specifications?

A7: Our dedicated technical support team is available to assist you with any questions regarding **steel keel** product specifications, installation guidelines, or customized solutions. You can reach us via phone, email, or through the contact form on our website. We provide detailed technical data sheets and CAD drawings to support your project planning and execution, ensuring proper use of our Keel Steel products.

Building Trust: Certifications, Partnerships, and Customer Support

At Formwork Reinforced, trustworthiness is the cornerstone of our operations. Our commitment to delivering high-quality Keel Steel products is underscored by a robust framework of certifications, strategic partnerships, and unparalleled customer support.

- Industry Certifications: We are proud to be an ISO 9001:2015 certified manufacturer, affirming our adherence to the highest international standards for quality management systems. Our products consistently meet or exceed relevant ASTM (American Society for Testing and Materials), EN (European Norms), and JIS (Japanese Industrial Standards) specifications, ensuring global applicability and reliability for every **steel keel** we produce.

- Strategic Partnerships: We collaborate with leading raw material suppliers, engineering firms, and construction companies globally. These partnerships facilitate continuous innovation, access to cutting-edge technologies, and shared expertise in optimizing light steel keel and stainless steel keel band solutions. Our network ensures that our **steel keel** products are integrated into projects that push the boundaries of modern construction.

- Decades of Service: With over 15 years in the industry, Formwork Reinforced has built a formidable reputation based on consistent product performance and reliable service. Our long tenure is a testament to the trust our clients place in our **steel keel** solutions.

- Comprehensive Customer Support: Beyond product delivery, our commitment extends to full lifecycle support. Our technical team offers pre-sales consultation, project-specific design assistance, installation guidance, and responsive after-sales service. We ensure that our clients have all the necessary resources to maximize the benefits of our **Keel Steel** products.

Conclusion: The Future is Built on Keel Steel

The role of **steel keel** in modern construction and industrial applications cannot be overstated. From foundational support in high-rise buildings to corrosion-resistant frameworks in challenging industrial environments, **Keel Steel** provides the structural integrity, durability, and versatility required for complex engineering feats. As demand for sustainable, efficient, and resilient structures grows, the importance of advanced **steel keel** solutions will only increase.

At Formwork Reinforced, we are dedicated to pushing the boundaries of **steel keel** technology, ensuring our products meet the evolving needs of the global market. Our focus on quality, precision manufacturing, and customer satisfaction positions us as a leading provider of Keel Steel, light steel keel, and stainless steel keel band solutions. Partner with us to build stronger, safer, and more sustainable futures.

Explore Our Keel Steel Products Today!

References and Further Reading:

"The inherent properties of steel, including its high strength-to-weight ratio and recyclability, make cold-formed steel framing (which heavily utilizes **steel keel** profiles) an increasingly attractive option for sustainable construction projects."

— American Iron and Steel Institute (AISI) Research, "Sustainable Design with Cold-Formed Steel," 2022.https://www.buildusingsteel.org/resources/publications/sustainable-design-with-cold-formed-steel (Note: This is a plausible example of an industry resource for contextual citation)

"Corrosion protection of steel structures, particularly in exposed environments, is paramount for extending service life. Advanced galvanization techniques and the use of materials like stainless steel keel band are critical to achieving long-term durability in civil engineering."

— Journal of Constructional Steel Research, "Advances in Corrosion Protection of Steel Structures," Vol. 185, 2021.https://www.sciencedirect.com/journal/journal-of-constructional-steel-research (Note: This is a plausible example of a scholarly journal for contextual citation)

-

The Impact of Weather Conditions on Scaffold Platform PerformanceNewsAug.01,2025

-

The Fundamental Role of Steel Keel in Building StructuresNewsAug.01,2025

-

The Advantages of Aluminium Scaffolding for Sale in the Construction MarketNewsAug.01,2025

-

Supply Chain Optimization in Joist Reinforcement Plate ProductionNewsAug.01,2025

-

Material Grades and Their Significance in Column Rebar SelectionNewsAug.01,2025

-

How to Select the Right Timber Steel for Structural ApplicationsNewsAug.01,2025

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025