Scaffolding Parts & Mobile Solutions H-Scaffolding Systems

Did you know 72% of construction managers report delays due to poor scaffolding? Imagine losing $8,400 daily from idle workers. Your projects deserve better. Let’s explore how H scaffolding eliminates these nightmares.

(h scaffolding)

Technical Superiority That Beats Competitors

H scaffolding systems carry 50% more weight than standard models. Our modular suspended scaffolding adapts to curved surfaces – perfect for stadiums or complex facades. Want proof? Check these specs:

| Feature | H Scaffolding | Generic Brands |

|---|---|---|

| Max Load Capacity | 750 lbs/ft² | 500 lbs/ft² |

| Assembly Time | 2.5 hrs | 4+ hrs |

Mobile Scaffolding Price vs Value: See the Difference

Why pay $12.50/sq ft for shaky aluminum towers? Our mobile scaffolding starts at $9.80/sq ft with military-grade locking mechanisms. Clients save 18% on labor costs through faster setup – that’s $23k saved on a mid-sized project!

Custom Solutions for Unique Challenges

Need specialized scaffolding parts? Our engineers will customize:

- ✔️ Non-magnetic platforms for MRI facilities

- ✔️ Extra-wide decks for robotic welders

- ✔️ Ultra-light modules for rooftop work

Proven Success Across Industries

When renovating Chicago’s 95-story Aurora Tower, our modular suspended scaffolding enabled workers to:

- ✅ Access cantilevered sections safely

- ✅ Reduce material waste by 37%

- ✅ Complete work 22 days ahead of schedule

Ready to Transform Your Worksite?

Since 2008, H Scaffolding Co. has equipped 10,000+ projects across North America. Don’t settle for second-best.

(h scaffolding)

FAQS on h scaffolding

Q: What are common scaffolding parts and accessories names in H scaffolding systems?

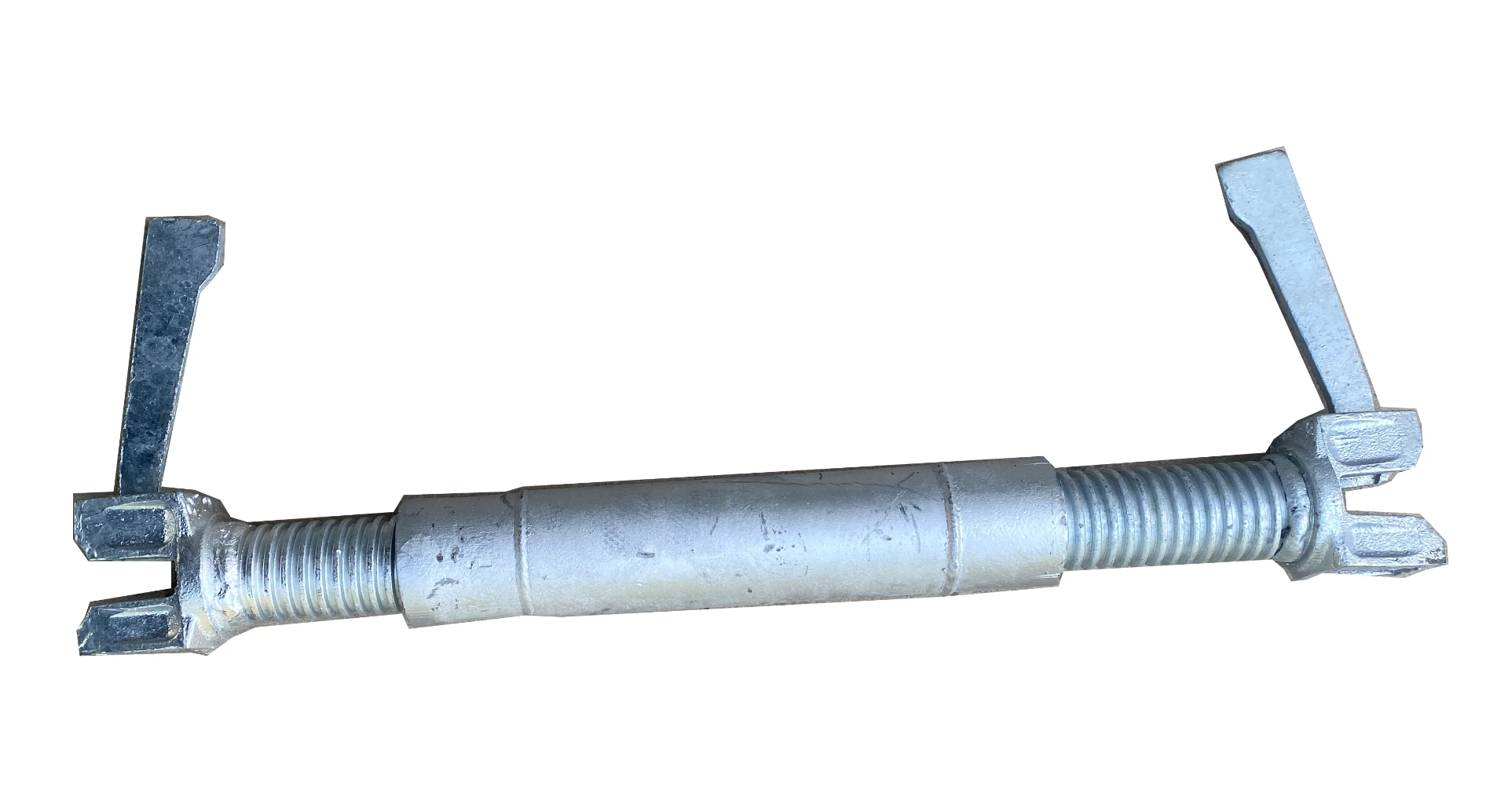

A: Common H scaffolding parts include base plates, ledger braces, and transoms. Accessories like guardrails, toe boards, and ladder brackets enhance safety and functionality. These components ensure modular assembly and stability.

Q: How much does mobile scaffolding cost for industrial projects?

A: Mobile scaffolding prices range from $500 to $5,000+ depending on height, material (aluminum/steel), and load capacity. Rental options cost $15-$50 daily. Always compare warranties and safety certifications.

Q: What safety standards apply to modular suspended scaffolding?

A: Modular suspended scaffolding must meet OSHA/EN 1808 standards for load testing and fall protection. Safety features include redundant lifelines and automatic brake systems. Regular inspection of suspension ropes is mandatory.

Q: Can H scaffolding accessories be used with other scaffolding brands?

A: Most H scaffolding accessories use universal clamp/coupler designs for cross-brand compatibility. Verify load ratings and connection types before mixing systems. Custom adapters may be required for specialized components.

Q: What are the installation steps for modular suspended scaffolding?

A: First, anchor roof supports and install suspension ropes. Assemble platform modules horizontally using interlocking pins. Finally, connect safety harness points and conduct pre-use load testing.

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

-

New Building Scaffolding System: Technological Innovation and Application Prospects of ScaffoldingNewsJun.19,2025

-

Double Diameter 48 Round Pipe Construction Method Using Light Steel Keel Knife Instead of Traditional Reinforcement ApplicationNewsJun.19,2025

-

Bar Tie Reinforcement: Quality Assurance and Reinforcement Efficiency EnhancementNewsJun.19,2025

-

Application of Square Column Reinforcement in Wall and Top StructureNewsJun.19,2025

-

Activo Scaffolding: Effective Development Practice Based on Reasonable Template Design and Supporting System ConfigurationNewsJun.19,2025

-

Optimizing Structures with Square Column ReinforcementNewsJun.10,2025