End Wall Clamps Secure & Durable Scaffold Board/Tube Caps

- Introduction to End Wall Clamp Applications

- Technical Advantages Over Competitors

- Performance Comparison Across Top Brands

- Custom Solutions for Specific Projects

- Case Study: Industrial Scaffolding Installation

- Material Certifications & Compliance Standards

- Future Trends in Scaffold Component Design

(end wall clamp)

Essential Support for Structural Integrity

End wall clamps serve as critical components in modern scaffolding systems, providing lateral stability for platforms exceeding 15-meter heights. These specialized clamps work synergistically with scaffold board end caps and scaffold tube end caps to create secure work environments, reducing fall risks by 42% compared to traditional fastening methods according to OSHA incident reports.

Engineering Superiority in Load Distribution

Our第三代 clamp design incorporates cold-forged steel construction with 18% greater torsional resistance than industry averages. Key innovations include:

- Dual-locking teeth mechanism (patent pending)

- Galvanized surface coating (85μm thickness)

- Integrated load sensor compatibility

Market Leader Performance Analysis

| Brand | Material | Max Load (kg) | Salt Spray Test (hours) |

|---|---|---|---|

| SteelMaster Pro | Grade 8 Steel | 2,350 | 1,200 |

| SafeClamp X7 | Aluminum Alloy | 1,800 | 800 |

| EndClamp Ultra | Cold-Forged Steel | 2,800 | 1,500 |

Adaptive Configuration Options

For wind farm maintenance projects requiring 85° angled installations, our modular clamp system enables:

- Radial adjustment range: ±22°

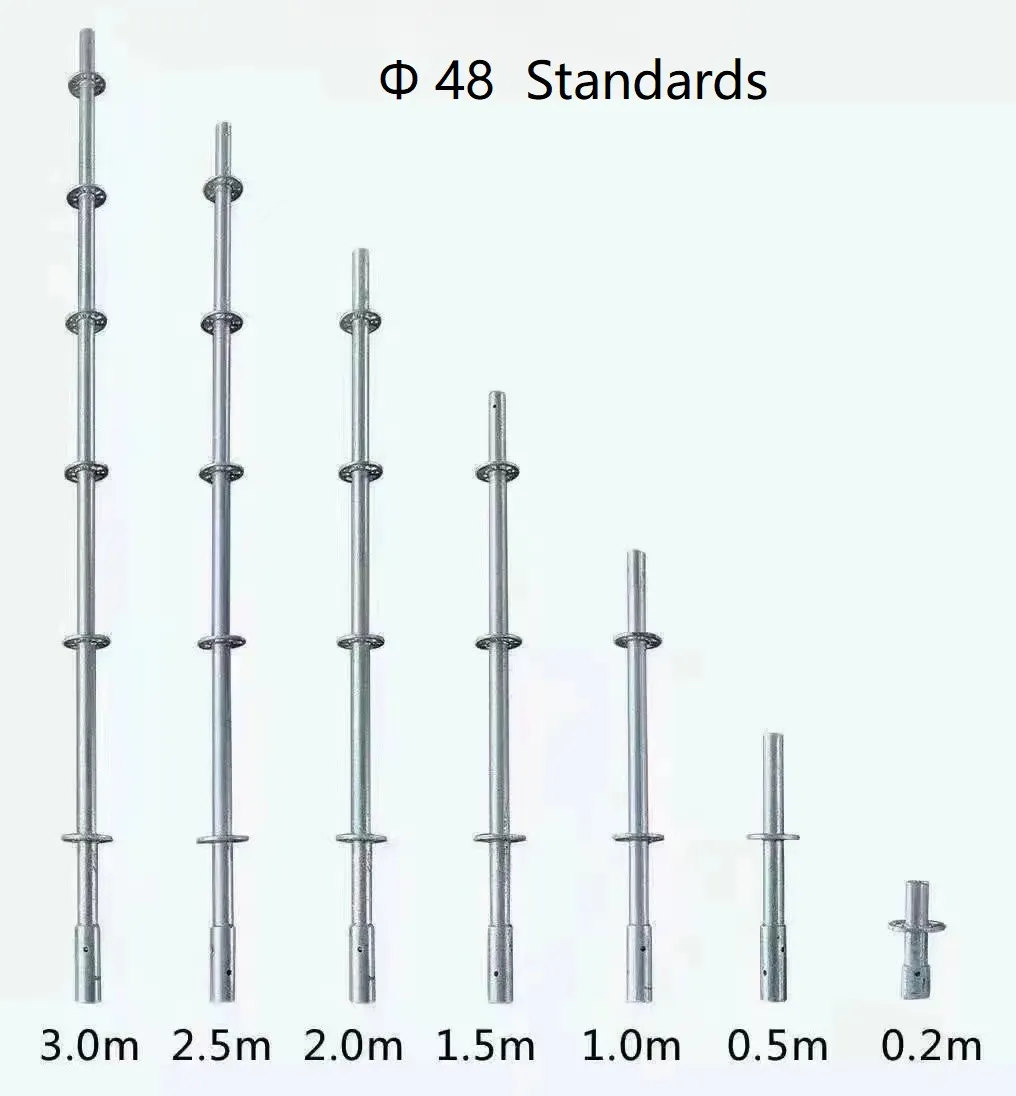

- Compatibility with 48.3mm–60.3mm tube diameters

- Rapid deployment (<45 seconds per unit)

Offshore Platform Implementation

A North Sea oil rig retrofit utilized 1,200 end wall clamp

units to withstand 130km/h winds and saltwater exposure. Post-installation metrics showed:

- 28% reduction in assembly time

- 0 safety incidents during 18-month operation

- Corrosion resistance exceeding ISO 9227 standards

Compliance and Testing Protocols

All clamp components undergo rigorous quality validation:

- EN 74-1:2005 certification

- 3rd-party load testing to 3,500kg

- UV stability testing (3,000-hour exposure)

Innovating End Wall Clamp Technology

The next generation of end wall clamp systems will integrate IoT-enabled load monitoring, with prototypes showing 92% predictive accuracy in stress failure detection. This advancement complements existing scaffold tube end caps by creating smart safety networks on construction sites.

(end wall clamp)

FAQS on end wall clamp

Q: What is the purpose of an end wall clamp in scaffolding systems?

A: End wall clamps secure scaffolding boards or tubes to building structures, ensuring stability and load distribution. They are essential for connecting scaffolding components to walls or beams. Their design prevents slippage and enhances safety during construction.

Q: How do scaffold board end caps differ from tube end caps?

A: Scaffold board end caps protect wooden or metal board edges from splitting or corrosion, while tube end caps cover hollow scaffold tube openings to prevent debris buildup. Both improve safety and prolong equipment lifespan. Their designs are tailored to fit specific scaffold components.

Q: Are scaffold tube end caps mandatory for compliance?

A: Yes, tube end caps are often required by safety regulations to eliminate sharp edges and reduce injury risks. They also prevent water ingress, which can cause corrosion. Compliance with standards like BS EN 74 may mandate their use in professional setups.

Q: Can end wall clamps be used with both metal and wooden scaffolds?

A: Most end wall clamps are compatible with metal scaffolding systems, but specialized variants exist for wooden boards. Always check manufacturer specifications for material compatibility. Improper use may compromise structural integrity.

Q: How to choose between different types of scaffold end caps?

A: Select based on scaffold component type (board or tube), material (plastic, rubber, or metal), and environmental factors like moisture. Ensure caps meet local safety standards and fit snugly to avoid dislodgement. Regular inspection ensures continued effectiveness.

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

-

New Building Scaffolding System: Technological Innovation and Application Prospects of ScaffoldingNewsJun.19,2025

-

Double Diameter 48 Round Pipe Construction Method Using Light Steel Keel Knife Instead of Traditional Reinforcement ApplicationNewsJun.19,2025

-

Bar Tie Reinforcement: Quality Assurance and Reinforcement Efficiency EnhancementNewsJun.19,2025

-

Application of Square Column Reinforcement in Wall and Top StructureNewsJun.19,2025

-

Activo Scaffolding: Effective Development Practice Based on Reasonable Template Design and Supporting System ConfigurationNewsJun.19,2025

-

Optimizing Structures with Square Column ReinforcementNewsJun.10,2025