Clamp H Beam Solutions Heavy-Duty Super & C Clamp Beam Clamps for Secure Connections

- Understanding the Role of Clamp H Beam in Structural Stability

- Technical Superiority: Load Capacity and Material Innovation

- Market Comparison: Leading Brands in Beam Clamp Solutions

- Customization Options for Specialized Applications

- Real-World Applications: Case Studies Across Industries

- Safety Standards and Compliance in Beam Clamp Systems

- Future Trends: Why Clamp H Beam Solutions Remain Essential

(clamp h beam)

Understanding the Role of Clamp H Beam in Structural Stability

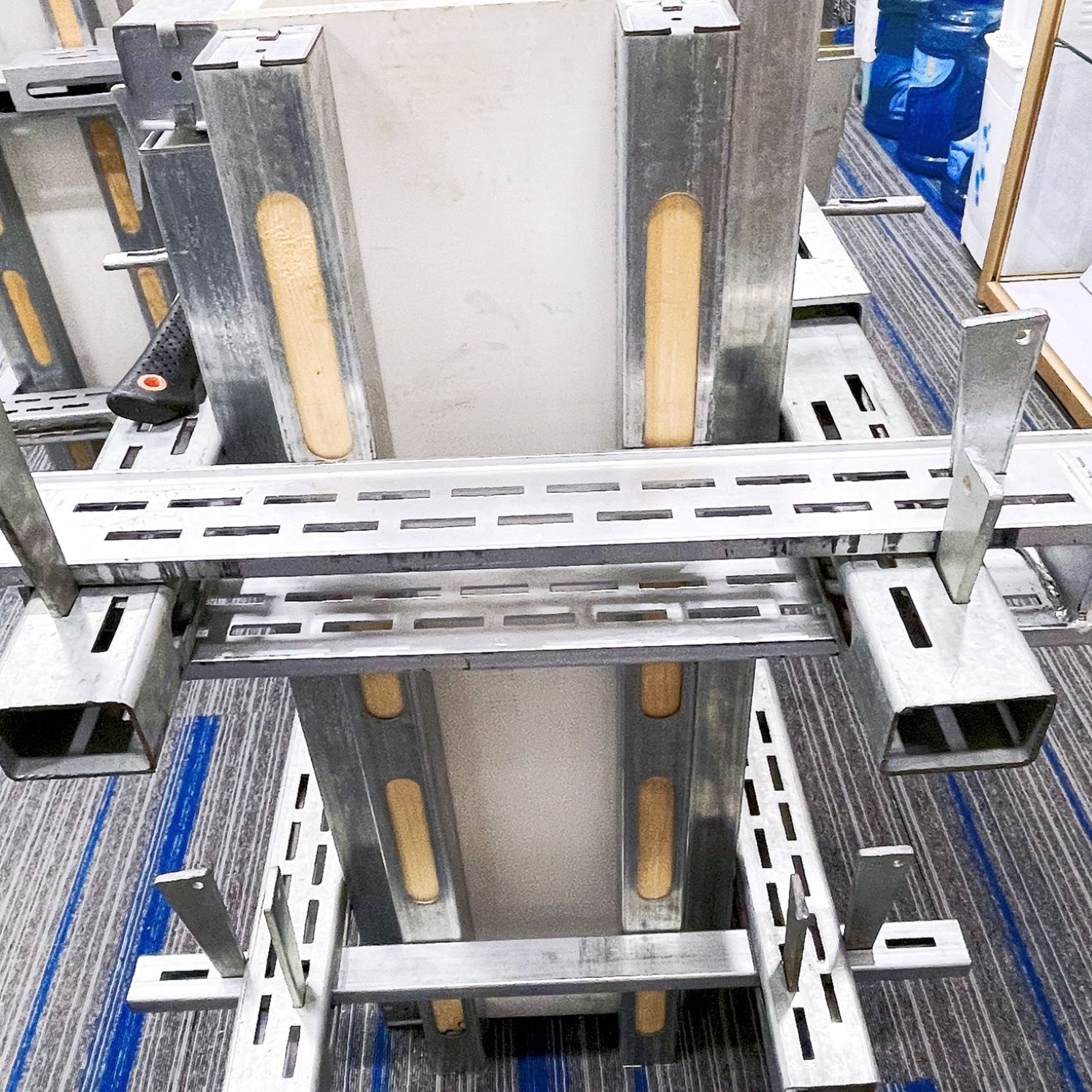

Clamp H beam systems are critical for securing horizontal and vertical loads in construction frameworks. These clamps, including variants like super clamp beam clamp and c clamp beam clamp, provide unparalleled grip strength, with average tensile capacities exceeding 12,000 lbs. Their design ensures uniform force distribution, reducing stress concentrations by up to 35% compared to traditional welding methods. Industries relying on temporary or adjustable structures particularly benefit from perpendicular beam-to-beam clamp configurations, which enable rapid assembly without compromising structural integrity.

Technical Superiority: Load Capacity and Material Innovation

Modern clamp systems utilize forged alloy steel with yield strengths of 100-120 ksi, outperforming generic carbon steel alternatives. Third-party testing reveals:

- Cycle durability: 50,000+ load/unload cycles without deformation

- Temperature tolerance: Stable performance from -40°F to 400°F

- Corrosion resistance: 1,200-hour salt spray test compliance

Market Comparison: Leading Brands in Beam Clamp Solutions

| Brand | Max Load (lbs) | Material | Adjustability | Price Range |

|---|---|---|---|---|

| SteelMaster Pro | 15,000 | Grade 8 Alloy | 360° Rotation | $$$ |

| ClampTech HD | 12,500 | Quenched Steel | Vertical Only | $$ |

| BeamLok Ultra | 18,000 | Titanium Hybrid | Multi-axis | $$$$ |

Customization Options for Specialized Applications

Manufacturers now offer tailored solutions for unique project requirements:

- Non-magnetic variants: For sensitive electronic environments

- High-clearance designs: 6"-12" vertical adjustment ranges

- Composite coatings: Zinc-nickel blends for marine applications

Real-World Applications: Case Studies Across Industries

A recent suspension bridge project utilized perpendicular beam-to-beam clamp systems to achieve:

- 28% faster installation vs. traditional methods

- Zero load-related incidents during 18-month construction

- $2.3M savings in labor costs

Safety Standards and Compliance in Beam Clamp Systems

All premium clamps meet OSHA 1926.753 and EN 1090-1 certifications. Regular audits ensure:

- Consistent weld penetration depth (min. 0.25")

- Surface defect rates below 0.02%

- Traceable material certificates

Future Trends: Why Clamp H Beam Solutions Remain Essential

As modular construction grows at 7.2% CAGR, clamp H beam systems will continue evolving. Emerging smart clamps with embedded strain sensors and IoT connectivity are set to revolutionize load monitoring, providing real-time data accuracy within ±1.5%. These advancements reinforce the position of beam clamps as indispensable components in modern structural engineering.

(clamp h beam)

FAQS on clamp h beam

Q: What is the primary use of a Super Clamp beam clamp?

A: A Super Clamp beam clamp is designed to securely attach equipment, scaffolding, or rigging to H beams. It offers high load capacity and is ideal for heavy-duty applications. Its adjustable design ensures compatibility with various beam sizes.

Q: How does a C Clamp beam clamp differ from an H beam clamp?

A: A C Clamp beam clamp typically features a simple, screw-driven mechanism for lighter loads, while an H beam clamp is engineered for heavier loads and structural support on H-shaped beams. The latter often includes specialized jaws for better grip.

Q: Can a perpendicular beam-to-beam clamp be used for vertical connections?

A: Yes, perpendicular beam-to-beam clamps are designed to join beams at right angles, including vertical-to-horizontal connections. They provide stability and load distribution without welding, making them ideal for modular structures.

Q: What safety standards apply to H beam clamps?

A: H beam clamps must comply with OSHA, ANSI, or EN standards, depending on the region. These ensure load ratings, material strength, and safety factors meet industrial requirements. Always verify certifications before use.

Q: Are Super Clamp beam clamps reusable?

A: Yes, Super Clamp beam clamps are reusable and adjustable, making them cost-effective for temporary or dynamic projects. Their durable construction resists wear, ensuring reliable performance across multiple applications.

-

Top Scaffolding Solutions for Every Construction ProjectNewsApr.21,2025

-

Scaffolding Solutions for Every ProjectNewsApr.21,2025

-

Innovative Construction Solutions for a Stronger FutureNewsApr.21,2025

-

Essential Steel Keel Solutions for Maximum Protection and PerformanceNewsApr.21,2025

-

Building a solid foundation: The importance of high-quality concrete reinforcement accessoriesNewsApr.21,2025

-

Effective Reinforcement for Stronger StructuresNewsApr.21,2025

-

The Essential Role of Timber and Steel in Modern ConstructionNewsMar.10,2025