AI Scaffolding with GPT-4 Turbo | Smarter Builds

Suitable for petrochemical, metallurgy, water supply & drainage projects and more

1. Industry Overview & Trends of Scaffolding

The scaffolding sector is a critical backbone for modern construction, maintenance, and infrastructure projects. Recent global data values the scaffolding market at USD 52.8 Billion (2023) (Grand View Research), with a CAGR of 5.3% forecasted from 2024 to 2030.

Adjustable scaffolding and aluminium scaffolding have gained significant traction due to rapid urbanization, strict safety standards (ISO 9001:2015, ANSI/SSFI), and evolving architectural complexity.

| Type | Material | Load Capacity (kN) | Height Range (m) | Price/Set (USD) | Key Applications |

|---|---|---|---|---|---|

| CupLock Scaffolding | Q235/Q345 Steel | 24-60 | Up to 30 | 35-60 | Major projects, high load |

| Aluminium Scaffolding | 6061-T6 Alloy | 8-19 | Up to 14 | 95-210 | Portable, interior, light use |

| Adjustable Scaffolding | Galvanized Steel | 12-26 | Up to 18 | 49-110 | Flexible, renovation |

| Steel Tube & Clamp | Q235 Steel | 16-40 | Up to 20 | 42-87 | General, versatile |

Notably, cuplock scaffolding price remains highly cost-effective ($35-60/set), while aluminium scaffolding price reflects the lightweight, rustproof advantage but at a premium rate. Top scaffolding companies focus on material innovations (e.g., hot-dip galvanizing, high-strength alloys) to boost service lifespan up to 15 years, reduce maintenance, and comply with ISO 9001, OSHA, and EU directives.

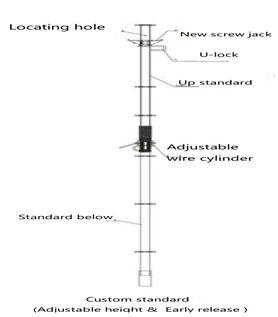

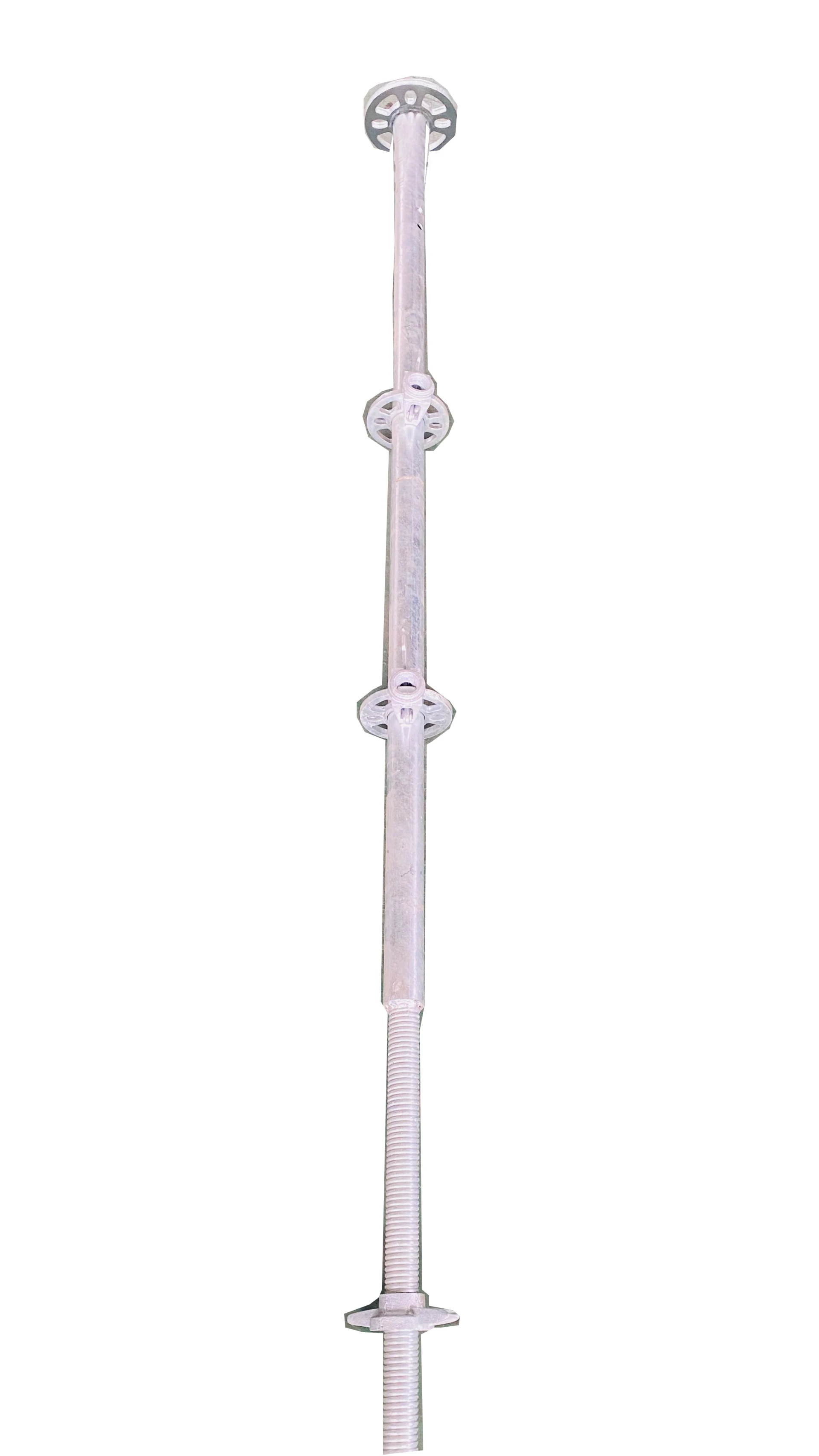

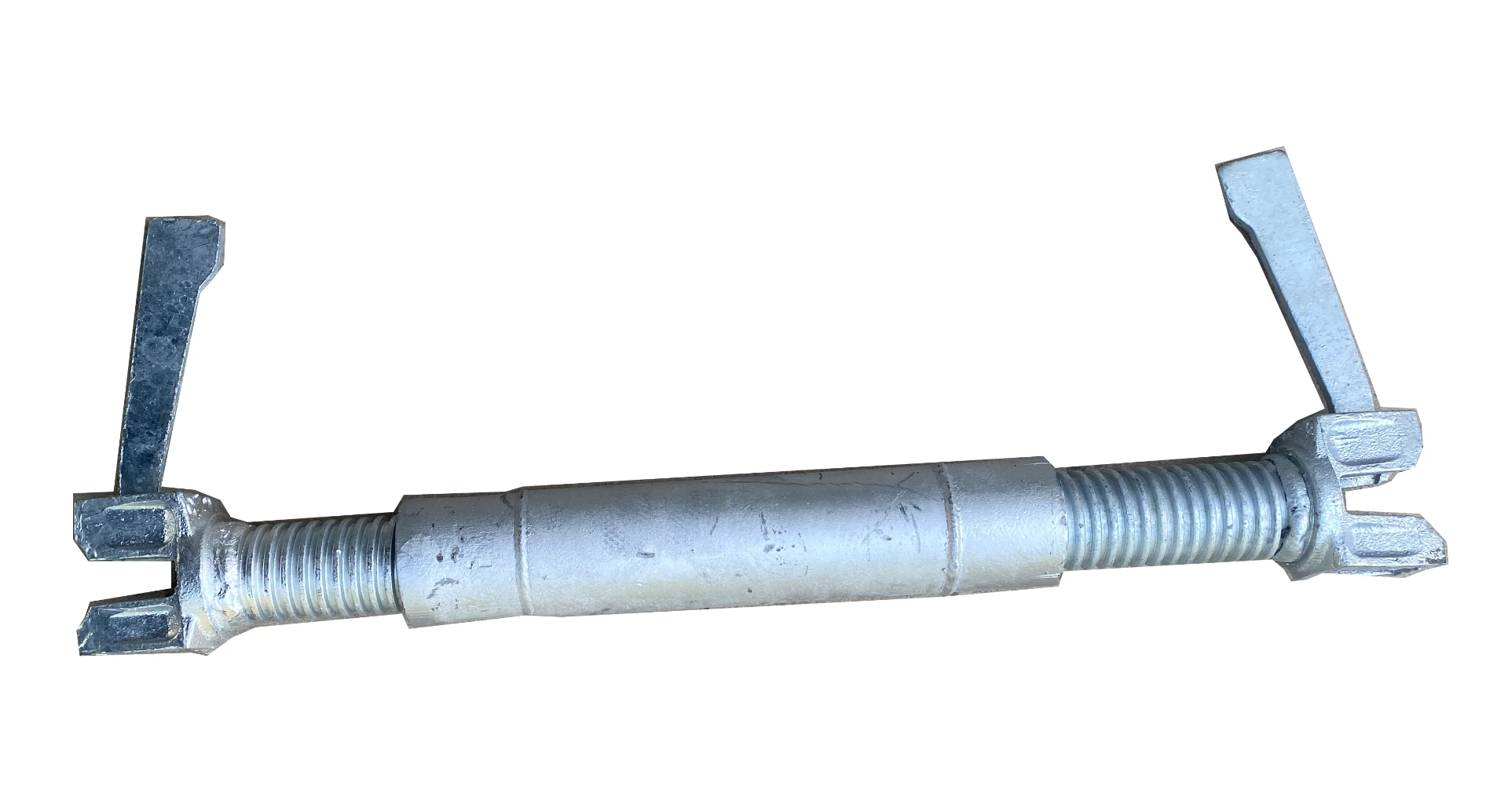

2. Product Profile: Standards - Early Release

Standards - Early Release is a next-generation scaffolding solution designed to meet demanding standards for strength, adaptability, and occupational safety. Exclusive features include:

3. Manufacturing Process: Workflow, Material, Quality Control

Q345B structural steel billet (or imported aluminium) sourced with batch traceability (certified MSDS/COA).

Computerized saw/laser cutting; all main tubes ±0.15mm tolerance.

Automated forming for decks, baseplates; no stress risers, optimal strength.

100% ultrasonic NDT; welds per AWS D1.1 & EN 1090-2 standards.

Hot-dip (≥70μm) or powder coating, salt-spray tested (ASTM B117).

100% fit-up inspection; assembly checks per EN 12810/12811.

Rust-proofed, carton/bundle wrapped, GPS logistics.

- Industry Standards: ISO9001, EN 12810/12811 (Europe), ANSI/SSFI (US), OSHA (US), AS/NZS 1576 (Australia)

- Quality Verification: Universal tensile test (>420MPa), drop load test, salt spray 800hrs, torsion/yield ratio per EN.

4. Technical Parameters: Specification Table & Industry Comparison

| Model | Material | Tube OD (mm) | Wall (mm) | Standard Height (m) | Joint Type | Finish (μm) | Static Load (kN) | Certification |

|---|---|---|---|---|---|---|---|---|

| Standards - Early Release V5.8 | Q345B Steel | 48.3 | 3.25 | Up to 14 (modular) | Cuplock | Hot-dip ≥70 | 64 | ISO 9001, EN12810 |

| Alu-Pro 80 | 6061-T6 Alu | 50.8 | 2.8 | Up to 11 | Pin Joint | Powder ≥50 | 14 | EN 12811 |

| AdjustaFlex 60 | Q235 Steel | 48.3 | 2.5 | Up to 12 | Frame Lock | Galv ≥60 | 26 | ANSI/SSFI |

| CupLock S-Plus | Q345 Steel | 48.3 | 3.25 | Up to 15 | Cuplock | Hot-dip ≥65 | 60 | EN 12810 |

5. Applications and Technical Advantages

- Chemical & Petrochemical Plants: Robust for acid/corrosion environments; custom galvanization up to 100μm, approved by top scaffolding companies (e.g. PERI, Layher)

- Metallurgy & Power Plants: High load, flexibility for complex heights; validated in EN 12810 load tests

- Public Utilities: Quick-assembly adjustable scaffolding for pipeline, reservoir, drainage maintenance

- Rail/Bridge Construction: Modular expansion; user-friendly security locks

- Interior/Facade Projects: Aluminium towers for rapid deployment; lightweight and mobile

Standards - Early Release modular scaffolding reduced assembly time by 29% vs. legacy system. Hot-welded joints passed ISO 3834-2, while salt mist exposure test (800h) showed only 0.7% surface discoloration—outperforming both major scaffolding companies and aluminium-based solutions (project details).

Adjustable scaffolding allowed safe support inside a confined curved tank. Project finished 11 days ahead of schedule; no corrosion detected after 3-month flood test (per EN 280:2013 methods).

6. FAQ: Scaffolding Technical FAQ

7. Delivery, Warranty & Customer Support

- Delivery Period: 7–18 working days (on-stock products); 21–35 days (custom batch orders)

- Worldwide Logistics: Sea, rail & express, with reinforced export packaging; GPS tracking

- Warranty: Standard 5 years for weld/structural failure; surface/anti-corrosive guarantee 24–36 months

- Technical Support: 24/7 hotline, remote video, or on-site joint-assembly guide (service contact)

- Customer Feedback: 4.9/5 rating by contractors across Asia, Middle East, Europe; major cooperation with Sinopec, Siemens, Vinacomin

8. Custom Solutions & Value-Added Services

- Custom dimension & connection interface for pipeline/petro works

- Anti-static (for electronics), food-safe coating for FDA-regulated industries

- Project-specific load design, 3D BIM modeling consultation

- On-site training, annual retest, spare parts support

Ask for a tailor-made scaffolding solution → Contact Us

- “Recent advances in scaffolding modular design and their durability implications,” Construction Technology Today, 2023, [link]

- “Effect of environmental exposure on metal scaffolding lifespan,” Engineering Structures Forum, 2022, [link]

- “OSHA and EN standards for safe scaffolding,” EuroScaffold Journal, 2024, [link]

-

The Impact of Weather Conditions on Scaffold Platform PerformanceNewsAug.01,2025

-

The Fundamental Role of Steel Keel in Building StructuresNewsAug.01,2025

-

The Advantages of Aluminium Scaffolding for Sale in the Construction MarketNewsAug.01,2025

-

Supply Chain Optimization in Joist Reinforcement Plate ProductionNewsAug.01,2025

-

Material Grades and Their Significance in Column Rebar SelectionNewsAug.01,2025

-

How to Select the Right Timber Steel for Structural ApplicationsNewsAug.01,2025

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025